33

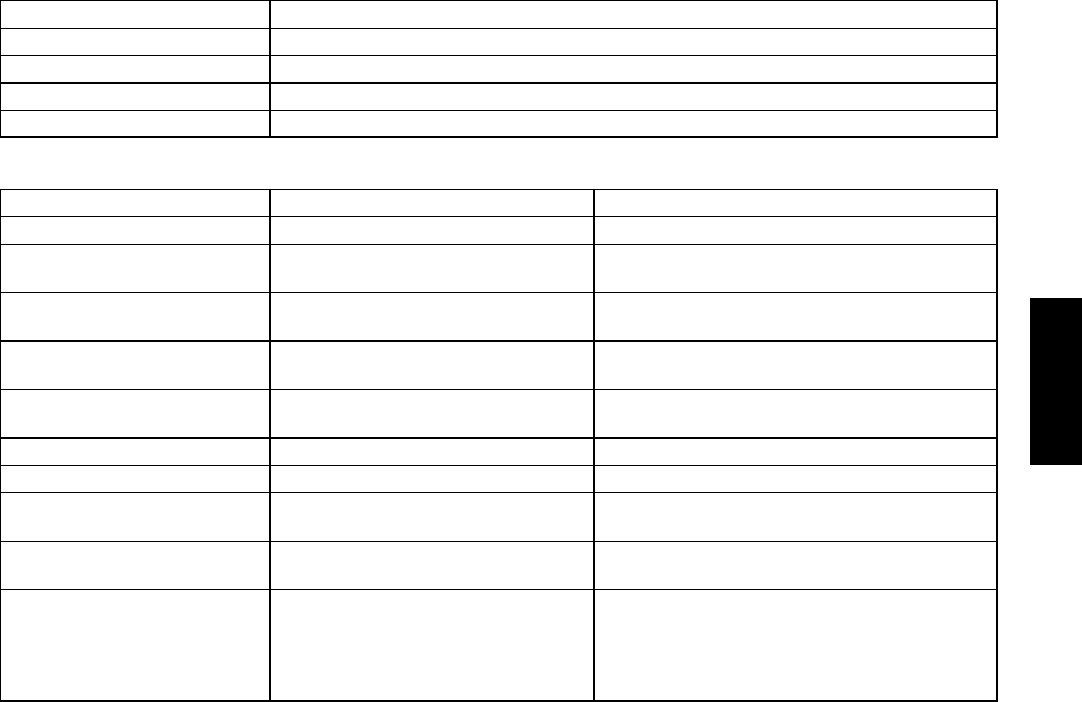

Table 9 – LEDs

The LEDs on the RTU--MP show the status of certain functions

If this LED is on... Status is...

Power The RTU MP has power

Rx The RTU MP is receiving data fro m the network segment

Tx The RTU MP is transmitting data over the network segment

DO# The digital output is active

The Run and Error LEDs indicate control module and network status

If Run LED shows...

And Error LED shows... Status is...

2 flashes per second Off Normal

2 flashes per second

2flashes,

alternating with Run LED

Five minute auto---restart delay after system error

2 flashes per second

3flashes,

then off

Control module has just been formatted

2 flashes per second

4flashes,

then pause

Two or more devices on this network have the

same ARC156 network address

2 flashes per second On

Exec halted after frequent system errors o r

control programs halted

5 flashes per second On Exec start---up aborted, Boot is running

5 flashes per second Off Firmware transfer in progress, Boot is running

7 flashes per second

7 flashes per second, alternating with

Run LED

Ten second recovery period after brownout

14 flashes per second

14 flashes per second,

alternating with Run LED

Brownout

On On

Failure. Try the following solutions:

S Turn the RTU---MP off, then on.

S Format the RTU --- MP.

S Download memory to the RTU---MP.

S Replace the RTU---MP.

NOTE: Refer to Form 48--50H--T--2T for complete

configuration of RTU--MP, operating sequences and

troubleshooting information. Refer to RTU--MP 3rd Party

Integration Guide for details on configuration and

troubleshooting of connected networks. Have a copy of these

manuals available at unit start--up.

Smoke Detectors

Smoke detectors are available as factory--installed options on

50HCQ models. Smoke detectors may be specified for

Supply Air only or for Return Air without or with

economizer or in combination of Supply Air and Return Air.

Return Air smoke detectors are arranged for vertical return

configurations only. All components necessary for operation

are factory--provided and mounted. The unit is

factory--configured for immediate smoke detector shutdown

operation; additional wiring or modifications to unit terminal

board may be necessary to complete the unit and smoke

detector configuration to meet project requirements.

Units equipped with factory--optional Return Air smoke

detectors require a relocation of the sensor module at unit

installation. See “Completing Installation of Return Air

Smoke Sensor:” on page 35 for details.

System —

The smoke detector system consists of a four--wire

controller and one or two sensors. Its primary function is

to shut down the rooftop unit in order to prevent smoke

from circulating throughout the building. It is not to be

used as a life saving device.

Controller —

The controller (see Fig. 58) includes a controller housing,

a printed circuit board, and a clear plastic cover. The

controller can be connected to one or two compatible duct

smoke sensors. The clear plastic cover is secured to the

housing with a single captive screw for easy access to the

wiring terminals. The controller has three LEDs (for

Power, Trouble and Alarm) and a manual test/reset button

(on the cover face).

Sensor —

The sensor (see Fig. 59) includes a plastic housing, a

printed circuit board, a clear plastic cover, a sampling

tube inlet and an exhaust tube. The sampling tube (when

used) and exhaust tube are attached during installation.

The sampling tube varies in length depending on the size

of the rooftop unit. The clear plastic cover permits visual

inspections without having to disassemble the sensor. The

cover attaches to the sensor housing using four captive

screws and forms an airtight chamber around the sensing

electronics. Each sensor includes a harness with an RJ45

terminal for connecting to the controller. Each sensor has

four LEDs (for Power, Trouble, Alarm and Dirty) and a

manual test/reset button (on the left--side of the housing).

50HCQA