15

a38-7099_gs

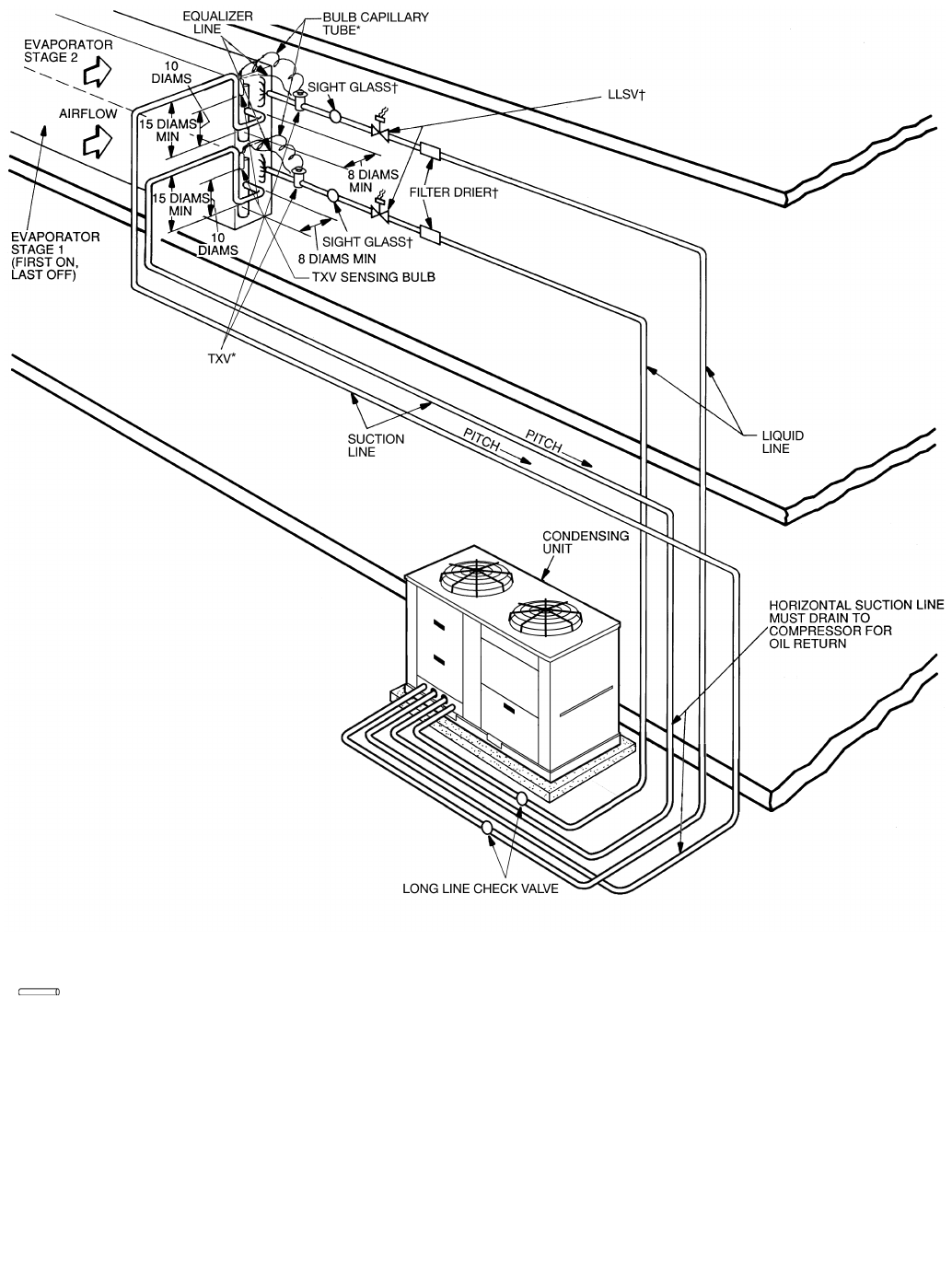

NOTES:

1. All piping must follow standard refrigerant piping techniques. Refer to Carrier System

Design Manual for details.

2. All wiring must comply with the applicable local and national codes.

3. Wiring and piping shown are general points-of-connection guides only and are not

intended for, or to include all details for, a specific installation.

4. Install field-supplied disconnect switch in accordance with all local and national electri-

cal codes.

5. Liquid line solenoid valves (solenoid drop control) are not required but are recom-

mended to prevent refrigerant migration to the compressor.

6. Factory-supplied accumulator not shown.

7. Dual-circuit piping shown. Single-circuit piping is similar but would only have one suc-

tion line and one liquid line.

8. A field-supplied, 5% bleed port TXV is required for every application.

9. Sight glass, LLSV, and filter drier are field supplied.

10. Long line length check valves are required for liquid line installation on all linear line

length applications of more than 100 ft (30.5 m). For any 025-030 size dual-circuit unit

application where evaporator is located higher than the condensing unit, check valves

are required for linear line length above 55 ft (16.8 m).

LEGEND

*Field supplied.

†Field supplied. See Table 6 for refrigerant spe-

cialties part numbers.

LLSV — Liquid Line Solenoid Valve

NEC — National Electrical Code

TXV — Thermostatic Expansion Valve

Piping

Fig. 11 — 38AP Unit Ground Level Installation