31

5.3 - Evaporator water pump control

The unit can control one or two evaporator water pumps. The

evaporator water pump is turned on when this option is

configured (see User configuration) and when the unit is in one

of the on modes described above or in delay mode. Since the

minimum value for the delay at start-up is 1 minute

(configurable between 1 and 15 minutes), the pump will run

for at least one minute before the first compressor starts. The

pump is kept running for 20 seconds after the unit goes to stop

mode. The pump keeps working when the unit switches from

heating to cooling mode or vice-versa. It is turned off if the

unit is shut down due to an alarm unless the fault is a frost

protection error. The pump can be started in particular

operating conditions when the evaporator heater is active (see

section 5.5). See section 5.14 for the particular evaporator

pump control for the follower unit (master/slave assembly).

If two pumps are controlled and the reversing function has

been selected (see User 1 configuration), the control tries to

limit the pump run time delta to the configured pump change-

over delay. If this delay has elapsed, the pump reversing

function is activated, when the unit is running. During the

reversing function both pumps run together for two seconds.

If a pump has failed and a secondary pump is available, the

unit is stopped and started again with this pump.

The control provides a means to automatically start the pump

each day at 14.00 hours for 2 seconds when the unit is off. If

the unit is fitted with two pumps, the first pump is started on

odd days and the second pump is started on even days. Starting

the pump periodically for few seconds increases the life-time

of the pump bearings and the tightness of the pump seal.

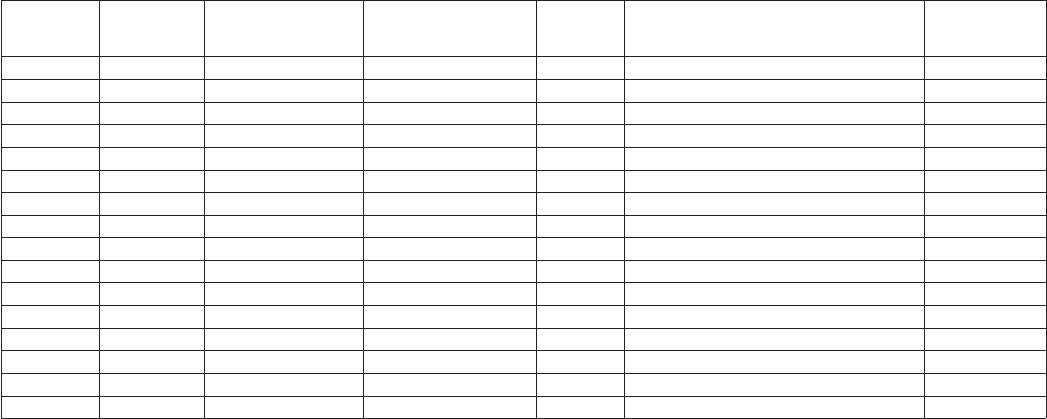

ON/OFF

STATUS

Off

On

On

On

On

On

On

On

On

On

On

On

On

On

On

On

CONTROL

TYPE

-

Local

Local

Local

Local

Local

Remote

Remote

Remote

Remote

Remote

CCN

CCN

CCN

CCN

CCN

HEATING/COOLING

SELECTION IN

LOCAL MODE

-

Cooling

Heating

Auto

Auto

Auto

-

-

-

-

-

-

-

-

-

-

REMOTE HEATING/

COOLING CONTACTS

-

-

-

-

-

-

Cooling mode

Heating mode

Auto mode

Auto mode

Auto mode

-

-

-

-

-

HC_SEL

-

-

-

-

-

-

-

-

-

-

-

Cooling

Heating

Auto

Auto

Auto

OUTDOOR TEMPERATURE

-

-

-

> Cooling threshold

< Heating threshold

Between cooling and heating thresholds

-

-

> Cooling threshold

< Heating threshold

Between cooling and heating thresholds

-

-

> Cooling threshold

< Heating threshold

Between cooling and heating thresholds

OPERATING

MODE

Cooling

Cooling

Heating

Cooling

Heating*

Standby

Cooling

Heating

Cooling

Heating*

Standby

Cooling

Heating

Cooling

Heating*

Standby

PARAMETER STATUS

5.4 - Control interlock contact

This contact checks the status of a loop (water flow switch and

customer safety loop, see section 3.6). It prevents the unit from

starting if it is open when the delay at start-up has expired. This

open contact leads to an alarm shut-down, if the unit is

running.

5.5 - Evaporator antifreeze protection

The heater for the evaporator and water pump cycling (for units

with a pump) can be energised to protect the evaporator, if it

can be damaged by freezing, when the unit is shut down for a

long time at low outdoor temperature.

NOTE: Evaporator heater control parameters can be

modified, using the Service configuration.

5.6 - Control point

The control point represents the water temperature that the unit

must produce. The inlet water is controlled by default, but the

outlet water can also be controlled (requires a Service

configuration modification).

Control point = active setpoint + reset

5.6.1 - Active setpoint

Two setpoints can be selected as active in cooling mode and

three in heating mode. Usually, the second cooling setpoint is

used for unoccupied periods or for ice storage (brine unit). The

second setpoint in heating mode is used for unoccupied

periods, and the third heating setpoint is used for holiday

periods or public holidays. Depending on the current opera-

tions, the active setpoint can be selected by choosing the item

in the Information menu, with the user’s volt-free contacts,

with network commands or with the setpoint timer program

(schedule 2).

* Does not apply to cooling only units that do not control a boiler.