Step 2 — Rig and Place Unit

RIGGING — The 09BY units are mounted on skids. Leave

the unit on the skid until it is in the final position. While on

the skid, the unit can be rolled, dragged or forklifted; do not

apply force to the unit. Use a minimum of 3 rollers when

rolling, and raise from above to remove the skid when unit

is in the final position. See Fig. 4 for rigging details.

PLACING THE UNIT — Locate the condenser where an

adequate supply of outdoor air is available for the unit inlet.

NOTE: Unit inlet and discharge may both be ducted to the

outside.

Either provide inlet filters to protect the condenser coils,

or locate the condenser in an area free from airborne dirt or

other foreign material which could clog the coils. For mul-

tiple units, allow service clearance (Fig. 3) between units,

and locate unit discharges and inlets so that recirculation of

condenser air is prevented. Placement area must be level and

strong enough to support operating weight of the unit

(Table 2). Bolt unit securely in place when unit is positioned

and leveled. Fasteners for mounting unit are field supplied.

NOTE: It will be necessary to drill holes in the unit base or

side wall where bolts are to be mounted.

IMPORTANT: Use care if rain will enter the unit (if

unit is located fully or partially outdoors). DO NOT

drill through the unit drain pan or leaks will result.

VIBRATION ISOLATION — Units mounted in or above

occupied spaces should employ some type of vibration iso-

lation. For units that are floor mounted, rubber pads may be

located under each unit corner or unit may be mounted on

rubber shear isolators or on spring isolators. Unit may be

supported by its 4 corners, or a field-supplied support rail

may be used for each side. Size isolators with the corner

weights shown in Fig. 3. Units may also be suspended from

above. See Positioning the 09BY Unit section below and

Fig. 5 for recommended support and isolator mounting.

Ductwork attached to the condenser should be isolated from

the unit with a flexible collar on the inlet and outlet ducts.

POSITIONING THE 09BY UNIT — Refer to notes in

Fig. 3 for typical service clearances.

To suspend the unit, use 4, field-supplied,

1

⁄

2

-in. diameter

(or larger) threaded rods. Mount 2 heavy channels under the

entire width of the unit, allowing them to protrude beyond

the width of the unit so that supporting rods can be installed

on the channel ends. Attach minimum

1

⁄

2

-in. threaded sup-

porting rods (field-supplied) to channels through a rubber or

spring isolator. See. Fig. 5.

DO NOT use rods smaller than

1

⁄

2

-in. diameter. Smaller

rods may not be strong enough to support the unit. Rods

must be securely anchored in ceiling joists.

Use a double hex nut when attaching hanger rods to brack-

ets.A single nut could loosen from vibration of the unit. Pitch

unit approximately

1

⁄

4

-in. toward drainin both directions (length-

wise and widthwise) to aid in condensate and/or rain

removal.

Before sliding unit into final position, check for clearance

to access panels and service area to install piping.

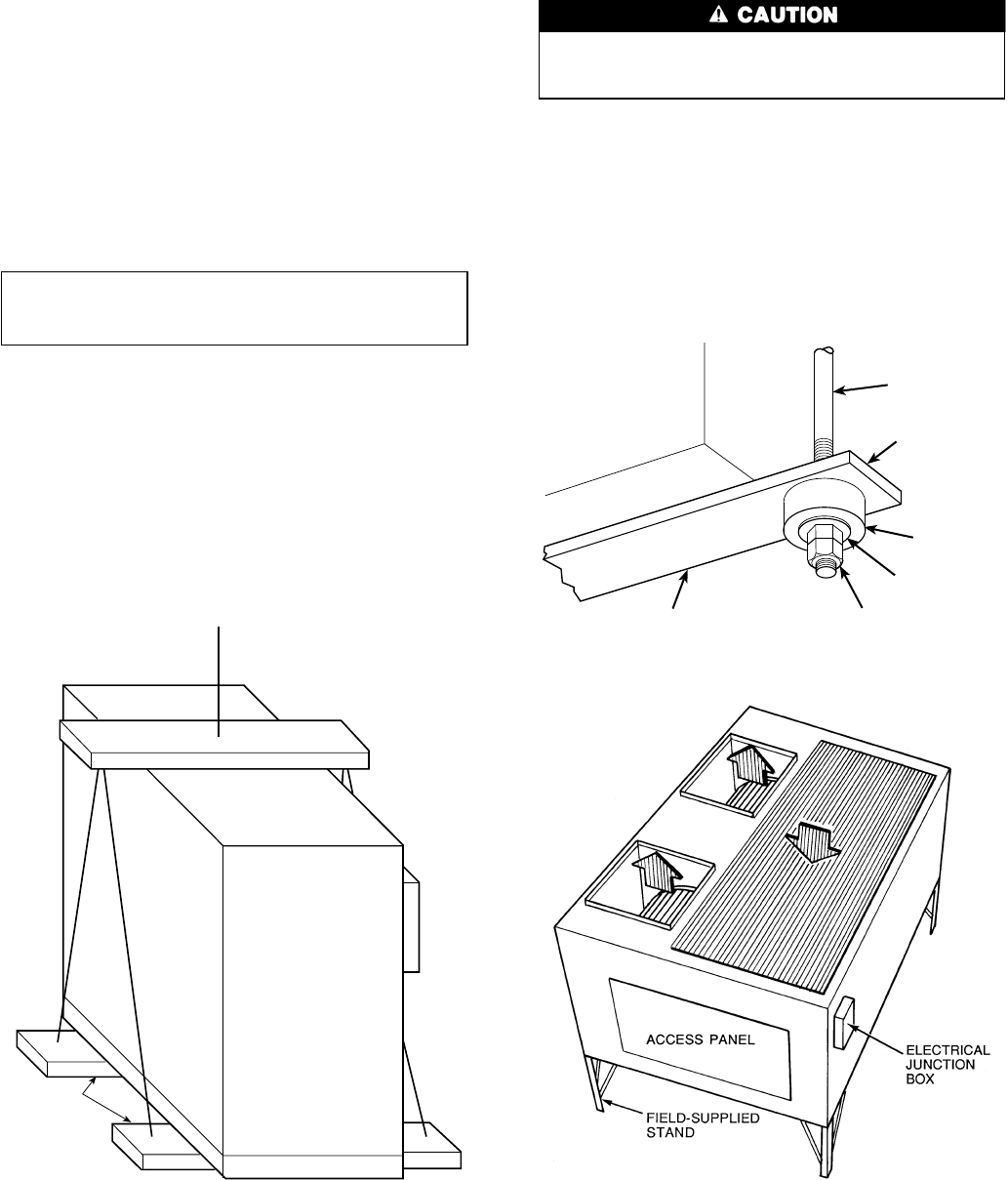

VERTICAL DISCHARGE— The 09BYunits can be mounted

on a field-supplied stand as shown in Fig. 6 for vertical dis-

charge. Also, provide a rain drain on the back of the unit.

SPREADER BAR

SUPPORTS

UNDER SKID

Fig. 4 — Unit Rigging

09BY

UNIT

BRACKET*

DOUBLE HEX NUT*

FIELD SUPPLIED

WASHER*

RUBBER

ISOLATOR*

PROTRUDING

CHANNEL END*

1/2" THREADED

ROD*

*Field supplied.

Fig. 5 — Threaded Rod Installed in Bracket

Fig. 6 — 09BY Vertical Discharge

7