START-UP

To prevent personal injury, be sure wire fan guards are

secured in place over each fan discharge (or that fans

are ducted) before starting the unit.

Complete Unit Start-Up Checklist on page CL-1 prior to

start-up of this system.

System Evacuation and Dehydration — Refer to

GTAC II, Module 4, ‘‘Dehydration for Proper Evacuation

and Dehydration Techniques.’’

Charging Procedure — BEFORE CHARGING THE

SYSTEM, INSTALL OR REPLACE THE FILTER DRI-

ER(S) CONNECTED TO THE LIQUID LINE IN THE

INDOOR UNITTO PREVENTCONTAMINATION WITHIN

THE SYSTEM. Refer to GTAC II, Module 5 ‘‘Charging,

Recovery, Recycling, and Reclamation’’for proper charging

techniques.

Check Operation of Condenser Fan Motor Con-

trols and Rotation of Fans —

Rotation should be

clockwise as viewed from belt access panel.

IMPORTANT: Check for proper fan rotation. If rota-

tion needs to be reversed, disconnect main power sup-

ply and switch any 2 leads at the load side of the dis-

connect switch.

Adjust Fan Speed — The 09BY units are belt-driven

condenser units and allow for a wide range of inlet static and

condenser airflow requirements. It may be necessary to ad-

just the condenser airflow to account for these inlet condi-

tions. Inadequate airflow will result in poor unit performance

and possible nuisance tripping of high-pressure switches.

If an airflow is not specified, use the nominal airflow from

Table 2 and adjust the fan speed to compensate for actual

job conditions. Use Table 5 to determine proper fan speed.

If the unit trips on high pressure due to high condensing tem-

perature, then it may be necessary to increase the fan speed

and condenser airflow.

SERVICE

Cleaning Condenser Coils

Do not use high-pressure water or air. Damage to fins

may result.

Clean coils with a vacuum cleaner, fresh water, com-

pressed air, or a bristle brush (not wire). Backflush coil to

remove debris. Commercial coil cleaners may also be used

to help remove grease and dirt. Steam cleaning is NOT rec-

ommended. Units installed in corrosive environments should

be cleaned as part of a planned maintenance schedule. In

this type of application, all accumulations of dirt should be

cleaned off the coil.

Lubrication — Fan motors have permanently lubricated

bearings.

Condenser Fan Adjustment

To prevent personal injury, be sure wire fan guards are

secured in place over each fan discharge (or that fans

are ducted) before starting the unit.

TO CHANGE FAN SPEED

1. Shut off unit power supply.

2. Loosen fan belt by loosening fan motor from mounting

bracket. Do not loosen fan motor mounting bracket from

unit.

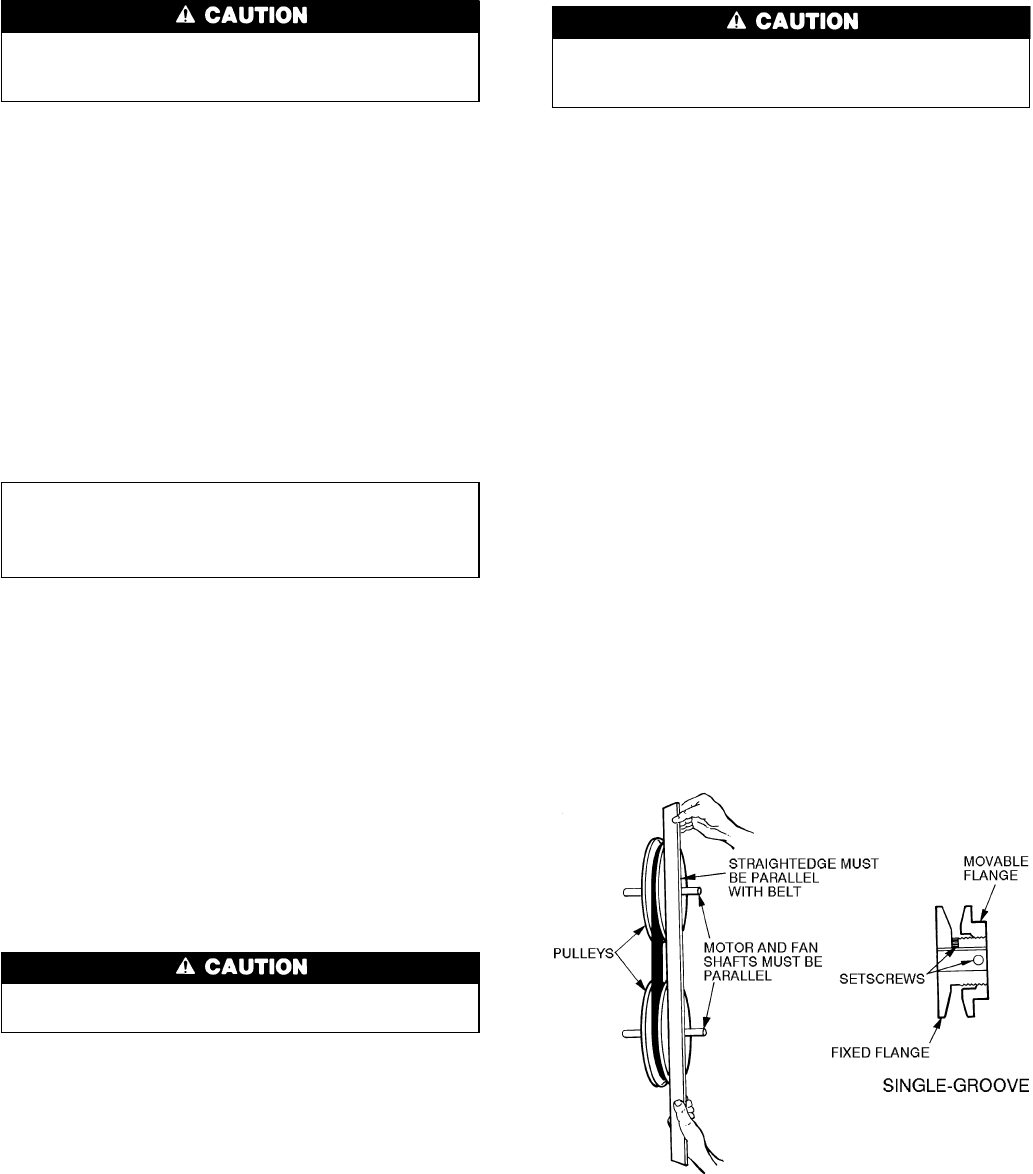

3. Loosen movable pulley flange setscrew (Fig. 12).

4. Screw movable flange toward fixed flange to increase fan

speed and away from fixed flange to decrease speed. In-

creasing fan speed increases load on motor. Do not ex-

ceed maximum allowable fan speed (Table 2) or motor

full load amps indicated on motor nameplate and in

Table 4.

5. Set movable flange setscrew at nearest flat of pulley hub

and tighten setscrew.

6. Check pulley alignment and belt tension adjustment as

described below.

7. Check fan operation. Repeat above procedure as

required.

PULLEYALIGNMENT — Shut off unit powersupply. Loosen

fan motor pulley setscrews and slide fan pulley along fan

shaft. Make angular alignmentby loosening motor from mount-

ing bracket (see Fig. 12). Check alignment with a

straightedge.

BELTTENSIONADJUSTMENT — Shut off unit power sup-

ply. Loosen fan motor mounting plate bolts. Do not loosen

motor mounting bracket from unit. Move fan motor mount-

ing plate until proper belt tension is achieved (approxi-

mately

1

⁄

2

-in. deflection with 8-lb tension at midpoint of belt

span).

Fig. 12 — Condenser Fan Pulley Adjustment

13