30

GUIDE SPECIFICATIONS — 569D072-120, 576C120 (cont)

J. Special Features:

1. Low-Ambient Temperature Control Accessory:

Low-ambient control shall be available as a factory-

installed option or a field-installed accessory and

shall regulate speed of condenser-fan motor in

response to the saturated condensing temperature

of the unit. The control shall maintain correct con-

densing pressure at outdoor temperatures down to

–20 F (fan motor change required for 569D and

576C units).

2. Optional Condenser Coil Materials:

a. Pre-Coated Aluminum-Fin Coils:

Shall have a durable epoxy-phenolic coating to

provide protection in mildly corrosive coastal envi-

ronments. Coating shall be applied to the alumi-

num fin stock prior to the fin stamping process to

create an inert barrier between the aluminum

fin and copper tube. Epoxy-phenolic barrier shall

minimize galvanic action between dissimilar

metals.

b. E-Coated Aluminum-Fin Coils:

Shall have a flexible epoxy polymer coating uni-

formly applied to all coil surface areas without

material bridging between fins. Coating process

shall ensure complete coil encapsulation. Color

shall be high gloss black with gloss requirements

of 60° of 65-90% per ASTM D523-89. Uniform dry

film thickness from 0.8 to 1.2 mil on all surface

areas including fin edges. Superior hardness char-

acteristics of 2H per ASTM D3363-92A and cross

hatch adhesion of 4B-5B per ASTM D3359-93.

Impact resistance shall be up to 160 in./lb (ASTM

D2794-93). Humidity and water immersion resis-

tance shall be up to a minimum of 1000 and

250 hours respectively (ASTM-D2247-92 and

ASTM D870-92). Corrosion durability shall be con-

firmed through testing to no less than 1000 hours

salt spray per ASTM B117-90. Coil construction

shall be aluminum-fins mechanically bonded to

copper tubes.

3. Thermostat Control Accessory:

a. Commercial Electronic Thermostat with 7-day

timeclock, auto-changeover, multi-stage capabil-

ity, and large LCD temperature display.

b. Commercial Electronic Non-programmable Ther-

mostat with auto-changeover, multi-stage capacity,

and large LCD display.

4. Hail Guard Accessory:

Hail guard package shall protect coils against dam-

age from hail and other flying debris.

5. Condenser Coil Grille Accessory:

Grille shall add decorative appearance to unit and

protect condenser coil after installation.

6. Electric Solenoid Unloader Accessory:

Electric unloader valve piston, coil, and hardware

shall be supplied to convert the pressure-operated

compressor unloader to electric unloading (576C120

only).

7. Unit-Mounted, Non-Fused Disconnect Switch:

Shall be factory-installed, internally mounted. NEC

and UL approved non-fused switch shall provide unit

power shutoff. Shall be accessible from outside the

unit and shall provide power off lockout capability.

Not to be used when rooftop electrical rating

exceeds 80 amperes.

8. Convenience Outlet:

Shall be factory-installed and internally mounted

with easily accessible 115-v female receptacle. Shall

include 15 amp GFI receptacle with independent

fuse protection. Voltage required to operate conve-

nience outlet shall be provided by a factory-installed

step-down transformer. Shall be accessible from out-

side the unit.

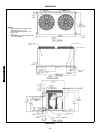

50TFQ004-012

569D072-120, 576C120, 569F120