—11—

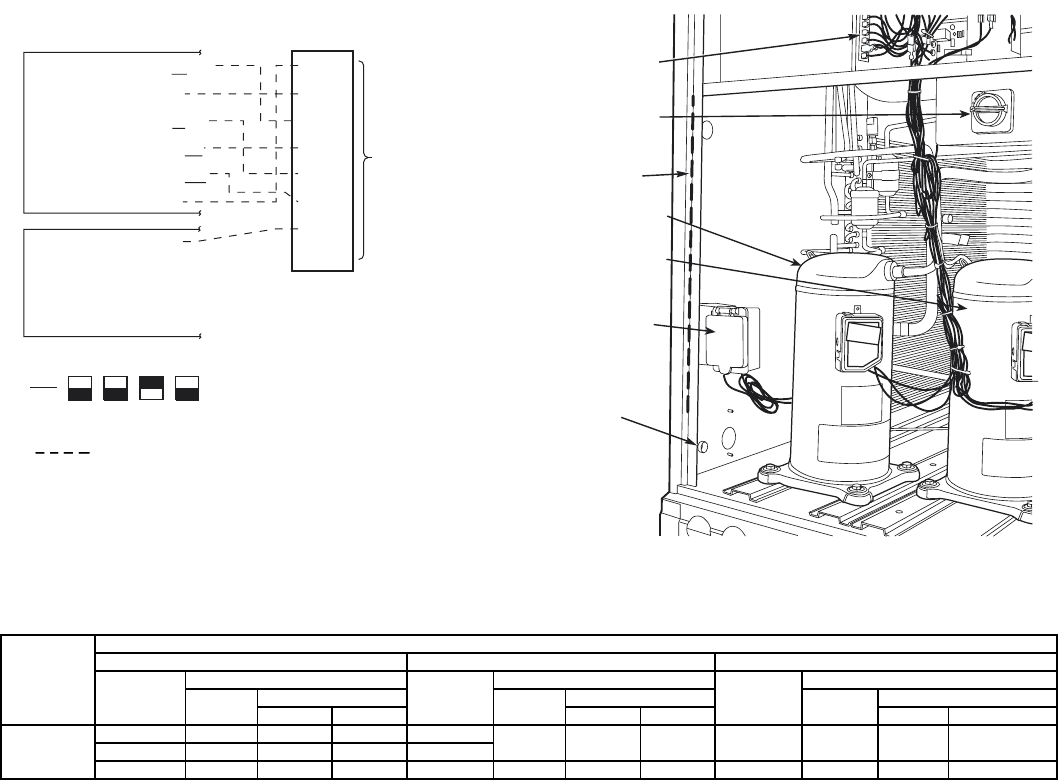

B. Field Control Wiring

Install a Bryant-approved accessory thermostat assembly

according to installation instructions included with the

accessory. Locate thermostat assembly on a solid wall in the

conditioned space to sense average temperature in accor-

dance with thermostat installation instructions.

Route thermostat cable or equivalent single leads of colored

wire from subbase terminals to low-voltage connections on

unit (shown in Fig. 9) as described in Steps 1 through 4 below.

NOTE: For wire runs up to 50 ft, use no. 18 AWG (American

Wire Gage) insulated wire (35 C minimum). For 51 to 75 ft,

use no. 16 AWG insulated wire (35 C minimum). For over

75 ft, use no. 14 AWG insulated wire (35 C minimum). All

wire larger than no. 18 AWG cannot be directly connected to

the thermostat and will require a junction box and splice at

the thermostat.

1. If mounted on a roof curb and electrical power is to be

run through the basepan, an accessory thru-the-

bottom connection kit is required. This is available

through the local Bryant distributor. This kit is

required to ensure a reliable water-tight connection.

2. If unit is mounted on roof curb and accessory thru-

the-bottom service connections are used, route wire

through connections.

3. Pass control wires through the hole provided on unit

(see connection D in Connection Sizes table in Fig. 7).

4. Feed wire through the raceway built into the corner

post to the 24-v barrier located on the left side of the

control box. See Fig. 9. The raceway provides the

UL required clearance between the high-voltage and

low-voltage wiring.

5. Connect thermostat wires to screw terminals of low-

voltage connector (see Fig. 9).

NOTE: If thru-the-bottom power connections are used refer

to the accessory installation instructions for information on

power wiring. Refer to Fig. 7 for drilling holes in basepan.

C. Heat Anticipator Settings

For units with electric heat, set heat anticipator settings as

shown in Table 4.

VI. STEP 6 — ADJUST FACTORY-INSTALLED OPTIONS

A. Disconnect Switch

The optional disconnect switch is non-fused. The switch has

the capability of being locked in place for safety purposes.

B. Perfect Humidity™ Dehumidification System

Perfect Humidity system operation can be controlled by field

installation of a Bryant-approved humidistat (Fig. 11), or

light commercial Thermidistat™ device (Fig. 12). To install

the humidistat:

1. Route humidistat cable through hole provided in unit

corner post.

2. Feed wires through the raceway built into the corner

post to the 24-v barrier located on the left side of the

control box. See Fig. 10. The raceway provides the

UL-required clearance between high-voltage and low-

voltage wiring.

Table 4 — Heat Anticipator Settings

*Heater capacity (kW) is based on heater voltage of 208 v, 240 v, 480 v or 575 v. If power distribution voltage to unit varies from rated heater voltage,

heater kW will vary accordingly.

UNIT

UNIT VOLTAGE

208/230 460 575

Heater

kW*

Configuration

Heater

kW

Configuration

Heater

kW

Configuration

1-Stage

2-Stage

1-Stage

2-Stage

1-Stage

2-Stage

Stage 1 Stage 2 Stage 1 Stage 2 Stage 1 Stage 2

551B

10.4, 16.0 0.3 NA NA 13.9, 16.5

0.3 NA NA 17.0, 34.0 0.3 NA NA

24.8, 32.0 0.6 0.3 0.3 27.8, 33.0

42.4, 50.0 0.9 0.6 0.3 41.7, 50.0 0.6 0.3 0.3 51.0 0.6 0.3 0.3

CONNECTION

BOARD

FACTORY-

INSTALLED

DISCONNECT

(OPTION)

RACEWAY

COMPRESSOR

NO. 2

COMPRESSOR

NO. 1

CONVENIENCE

OUTLET

(OPTION)

HOLE IN

END

PANEL

Fig. 10 — Field Control Wiring Raceway

WIRE

CONNECTIONS

TO

LOW-VOLTAGE

SECTION

(CONNECTION

BOARD)

COOL STAGE 1

FAN

HEAT STAGE 1

COOL STAGE 2

HEAT STAGE 2

24 VAC HOT

24 VAC COM

N/A

OUTDOOR AIR

SENSOR

Y1/W2

G

W/W1

Y/Y2

O/W2

R

C

S1

S2

THERMOSTAT DIPSWITCH SETTINGS

R

G

Y1

Y2

W1

W2

C

IPD/X

ON

OFF

A

B

C

D

LEGEND

NOTE: Underlined letter indicates active thermostat output when configured

for A/C operation.

Fig. 9 — Low-Voltage Connections

Field Wiring