SEWING BASICS — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

—

68

Sewing leathers or vinyl

fabrics

When sewing the fabrics that may stick to the presser

foot such as leathers or coated fabrics, change the

presser foot to the non stick foot.

a Leather

Sewing an even seam

allowance

To sew an even seam, start sewing so that the seam

allowance is to the right of the presser foot, and the

edge of the fabric is aligned with either the right edge

of the presser foot or a marking on the needle plate.

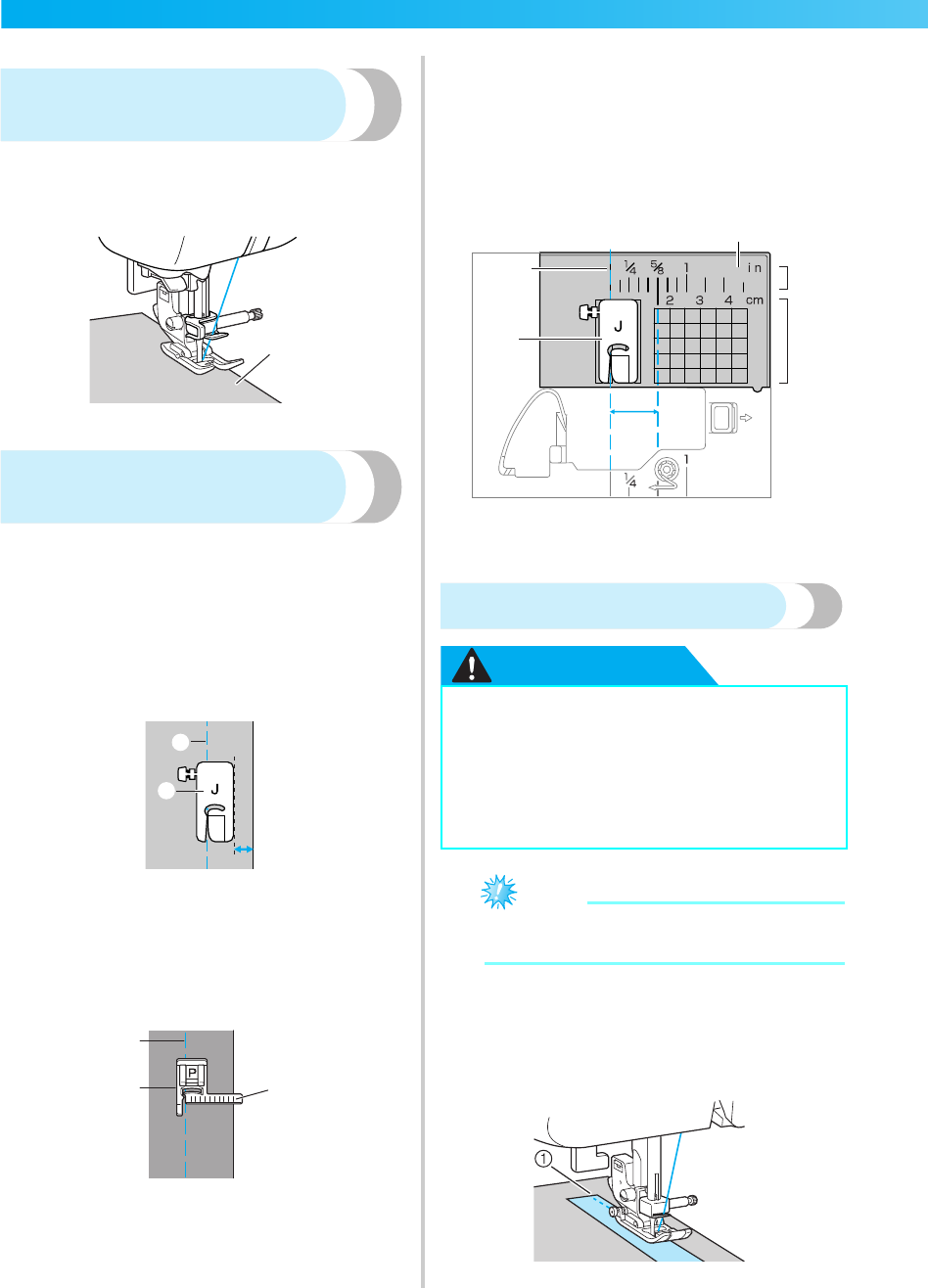

■ Aligning the fabric with the presser foot

Sew while keeping the right edge of the presser

foot a fixed distance from the edge of the fabric.

a Seam

b Presser foot

■ Aligning the fabric with the stitch guide foot

Sew while keeping the right edge of the fabric

aligned with a desired position of markings on the

stitch guide foot.

a Seam

b Stitch guide foot

c Markings

■ Aligning the fabric with a needle plate marking

The markings on the needle plate show the distance

from the needle position of a seam sewn with the

straight stitch (left needle position). Sew while keeping

the edge of the fabric aligned with a marking in the

needle plate. The distance between the markings in

the upper scale is 1/8 inch (3 mm) and the distance

between the markings in the grid is 5 mm (3/16 inch).

Sewing hook-and-loop fastener

CAUTION

Note

z Before start sewing, baste together the fabric

and the hook-and-loop fastener.

Make sure that the needle passes through the hook-and-loop

fastener by turning the handwheel and lower the needle into

the hook-and-loop fastener before sewing. And then, sew the

edge of the hook-and-loop fastener at a slow speed.

If the needle does not pass through the hook-and-loop fastener,

replace the needle with the needle for thick fabrics (page 38).

a Edge of the hook-and-loop fastener

1

1

2

1

2

3

a Seam

b Presser foot

c Centimeters

d Inches

e Needle plate

f 16 mm (5/8 inch)

● Use only the ungummed hook-and-loop

fastener which is for sewing. If the glue is

attached to the needle or the bobbin hook

race, it may cause malfunction.

● If the hook-and-loop fastener is sewn with

the thin needle (65/9-75/11), the needle

may bend or break.

6

4

3

5

2

1