APPENDIX — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

—

158

g

Correctly thread the machine.

• For details on threading the machine, refer to

“Upper Threading” (page 28).

Note

z The thread may have become tangled as a

result of incorrect upper threading. Make

sure that the machine is correctly threaded.

h

Perform trial sewing with normal fabric.

Note

z Incorrect sewing may be the result of

incorrect upper threading or sewing thin

fabrics. If there are poor results from the trial

sewing, check the upper threading or the

type of fabric being used.

When the thread became

tangled under the bobbin

winder seat

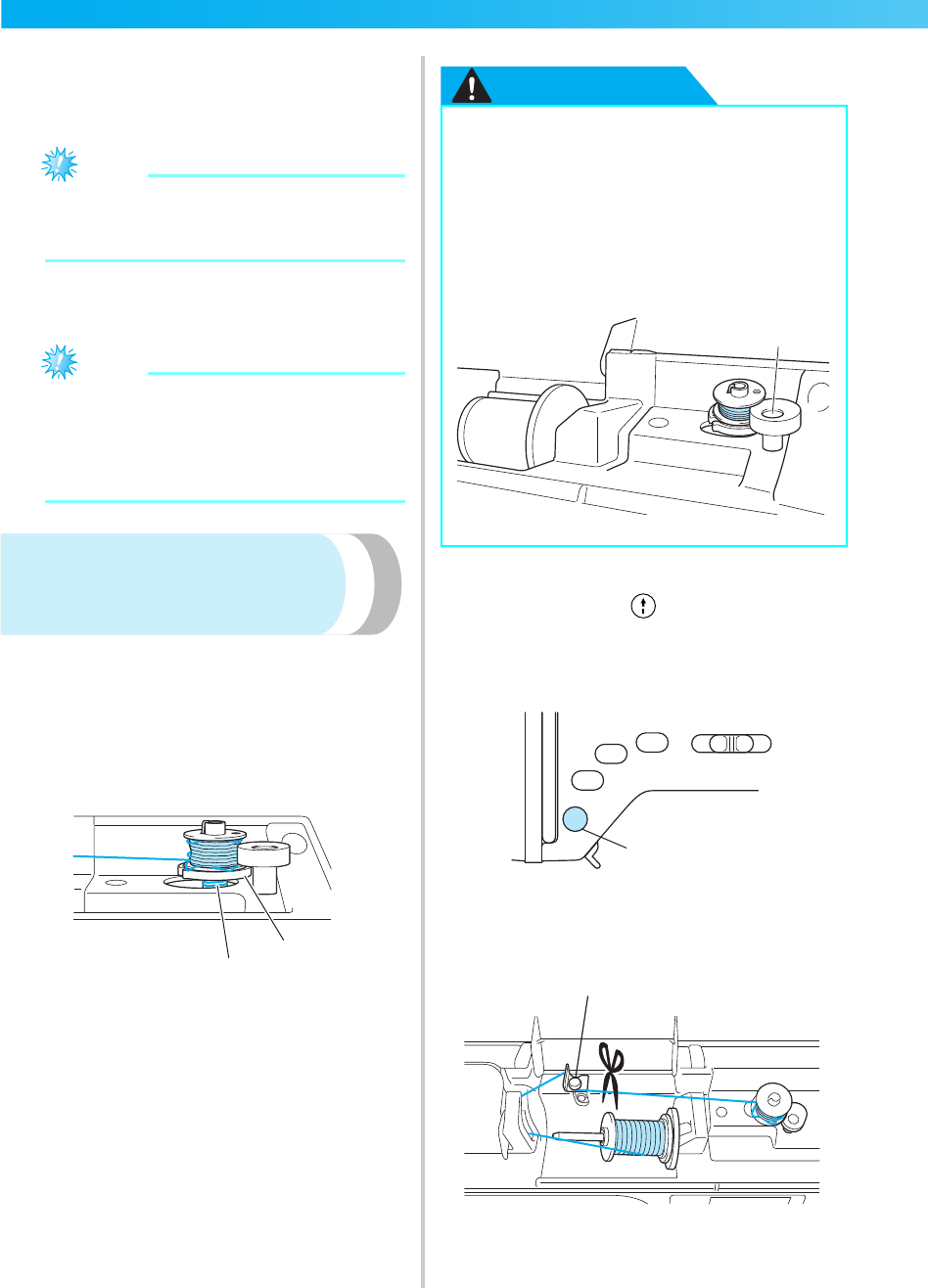

If the bobbin winding starts when the thread is not

passed under the pretension disk of the bobbin-

winding thread guide correctly, the thread may

become tangled under the bobbin winder seat.

In such a case, wind off the thread according to the

following procedure.

a Thread

b Bobbin winder seat

CAUTION

a

If the thread become tangled under the bobbin

winder seat, press (“Start/Stop” button)

once to stop the bobbin winding.

When the foot controller is plugged in, remove

your foot from the foot controller.

a “Start/Stop” button

b

Cut the thread with scissors beside the bobbin-

winding thread guide.

a Bobbin-winding thread guide

1

2

● Do not remove the bobbin winder seat

even if the thread become tangled under

the bobbin winder seat. It may result in

injuries.

● Do not remove the screw of the bobbin

winder presser, otherwise the machine

may be damaged; you cannot wind off the

thread by removing the screw.

a Screw of the bobbin winder presser

1

1

1