4. ASSEMBLY

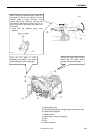

4-17. Work clamp arm mechanism (KE-433B)

KE-430B, 430C series

91

3429Q

Install parts 1 to 6, clamp them using

parts 7 and 8 so there is no play in them,

and tighten the set screw 9.

Note:

Install so that the two ball bearings of

the feed bracket guide shaft assembly

do not fit into the holes in the feed

bracket guide plate.

Be careful not to d

rop these three

ball bearings when installing the

work clamp arm assembl

y

.

1. Feed bracket guide plate

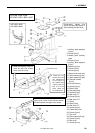

After installing, carry out test feeding and check that the needle hole is inside the work clamp and the

feed plate frame. If the needle hole is not inside the frame, adjust the position of the work clamp arm

assembly and feed plate.

Refer to “4-20. Work clamp arm

mechanism (Applying grease)”

3430Q

2. X

feed cover

Secure the work clamp

arm support shaft with the

set screw so that the

bottom of the work clamp

arm support plate and the

ball bearings touch when

the work clamp is raised.

3. Y

feed cover

4. Feed bracket assy

5. Spacers [2 pcs]

6. Retainer assys [2 pcs]

7. Feed bracket guide shaft assy

8. Tack length regulator block

9. Set screw

10. Cover support stand

11. Screw

12. Feed bracket cover

13. Screws [8 pcs]

14. Tack width feed shaft

15. Set screw

16. Rubber cap

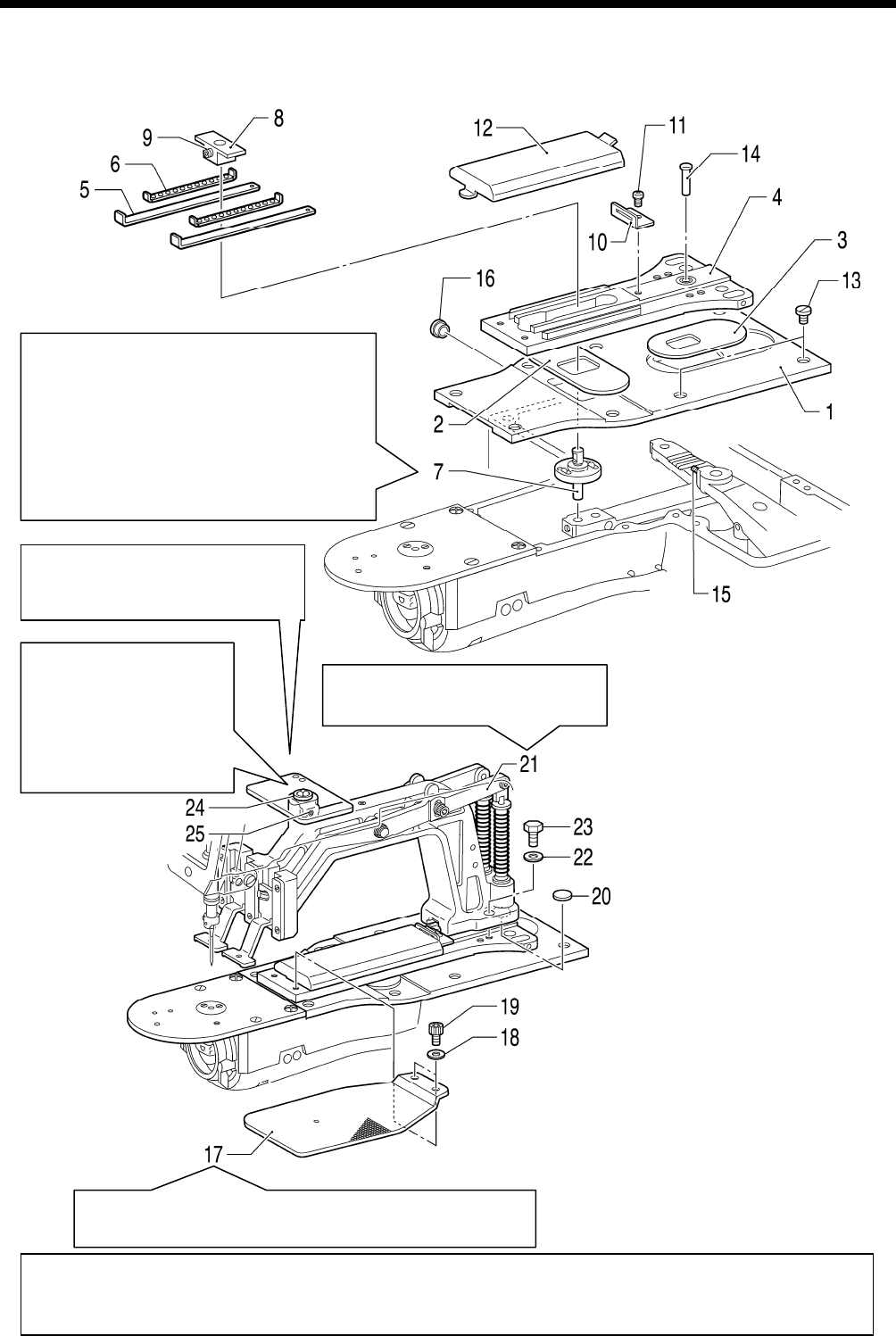

17. Feed plate

18. Plain washers [2 pcs]

19. Bolts [2 pcs]

20. Work clamp felt

21. Work clamp arm assy

22. Washers [2 pcs]

23. Bolts [2 pcs]

24

. Work clamp arm support shaft

Carry out the adjustment in “5-24. Adjusting the home

po

sition” before installing the feed plate.

25. Set

screw