4. ASSEMBLY

4-20. Work clamp arm mechanism (Applying grease)

Check that the mechanism moves smoothly and also apply grease to all sliding parts during assembly.

If the work clamp does not move up and down smoothly, error E-60 may be displayed. (for solenoid

specifications)

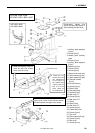

[KE-430B, 430C, 431B, 431C, 433B, 434B/434C solenoid specifications]

KE-430B, 430C series

95

<KE-431B, KE-431C>

3438

Q

3437Q

1.

Sliding portion of the work clamp (1) (Apply small amount of grease.)

2. Sliding portion of the work clamp arm lever shaft (2) and the work clamp arm levers R and L (3) [KE-430B,

430C, 433B, 434B/434C solenoid specifications]

Sliding portion of the work clamp lever B (4) and lever shaft bush (5) and work clamp lever A (6) [KE-431B,

431C]

3. Round portion of the work clamp arm lever plate (7)

4. Bearing ball of the work clamp arm support shaft (8) [KE-430B, 430C, 431B, 431C, 433B]

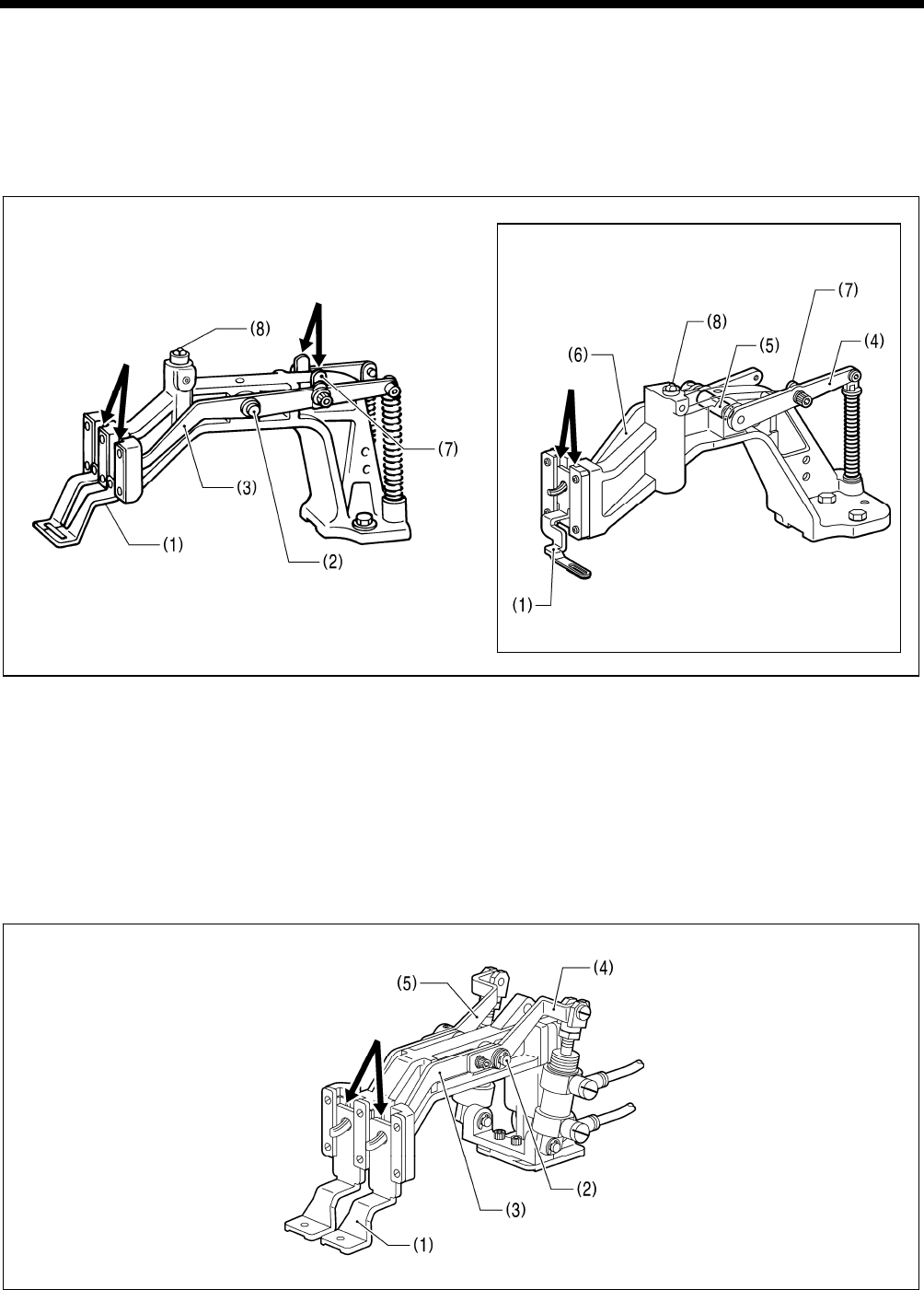

[KE-434B/434C pneumatic specifications, KE-435B, 435C, 436B, 436C, 484C]

3439Q

1.

Sliding portion of the work clamp (1) (Apply small amount of grease.)

2. Sliding portion of the work clamp arm lever shaft (2) and the work clamp arm lever F (3), the work clamp arm

lever RR(4) and RL (5)