5. CORRECT USE

BAS-341F, 342F

14

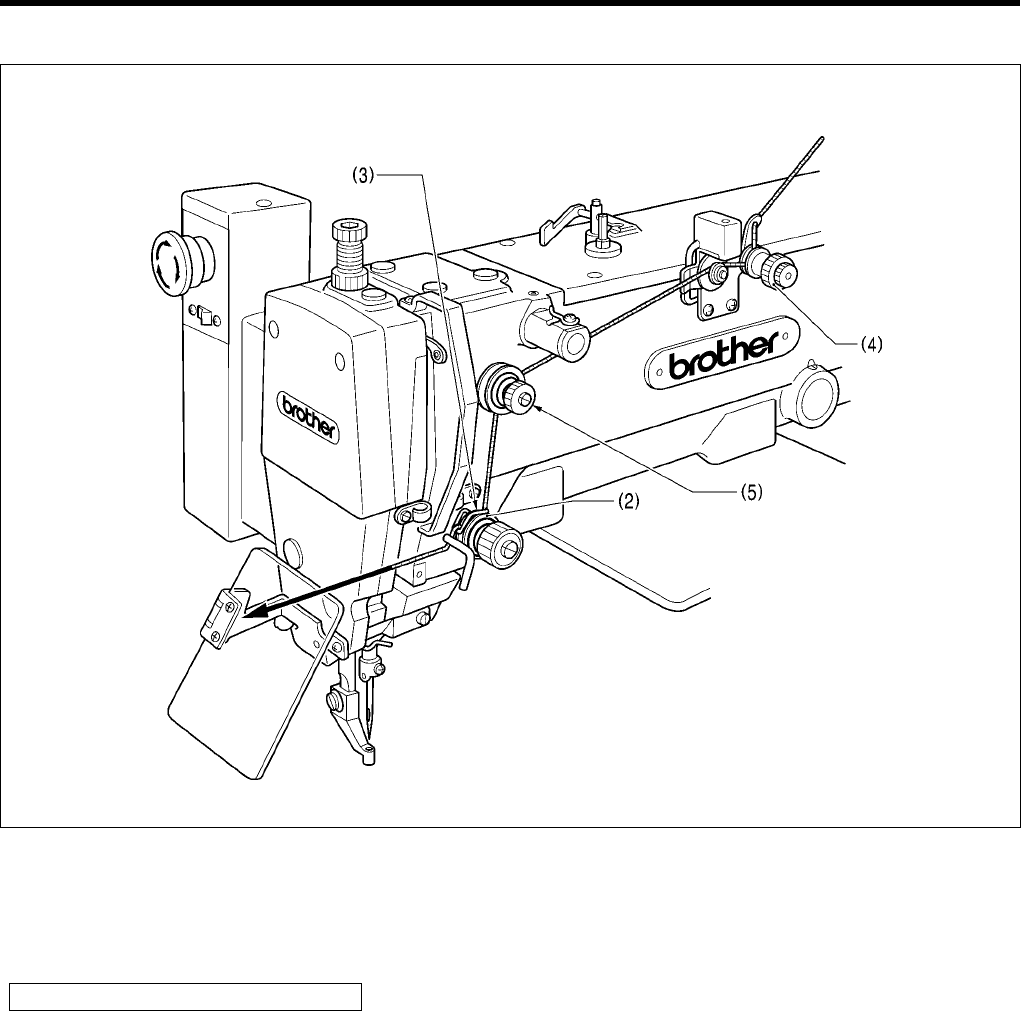

5-6-6. Pretension tension

1. Raise the work clamp (1) and open the main tension disc (2).

The thread take-up spring (3) should not operate when the thread is pulled in the direction of the arrow.

2. Set the thread tension for the thread breakage detector pretension (4) to approx. 5 g.

Weaken the thread tension for the machine head pretension (5) as much as possible.

Standard for balance of thread tension

Adjust the thread tensions so that the total tension for the pretensions (4) and (5) is lower than the tension for the thread

take -up spring.

When the thread breakage detector is activated, set to ON DIP switch A – 8.

(Detection precision : DIP switch B – 5, Refer to “ DIP SWTCH “.)

Note

If misoperation of the thread breakage detector continues, repeat the adjustment procedure above.

(Such misoperation is most likely to occur when synthetic fiber yarns are used.)

1940S