11

OPERATION

Starting the Water Pump

Use the following start instructions:

1. Make sure unit is on a flat, level surface and pump

chamber is primed.

2. Push primer bulb (Figure 14) 15 times for a new

engine. Push primer bulb 8 times for all future starts.

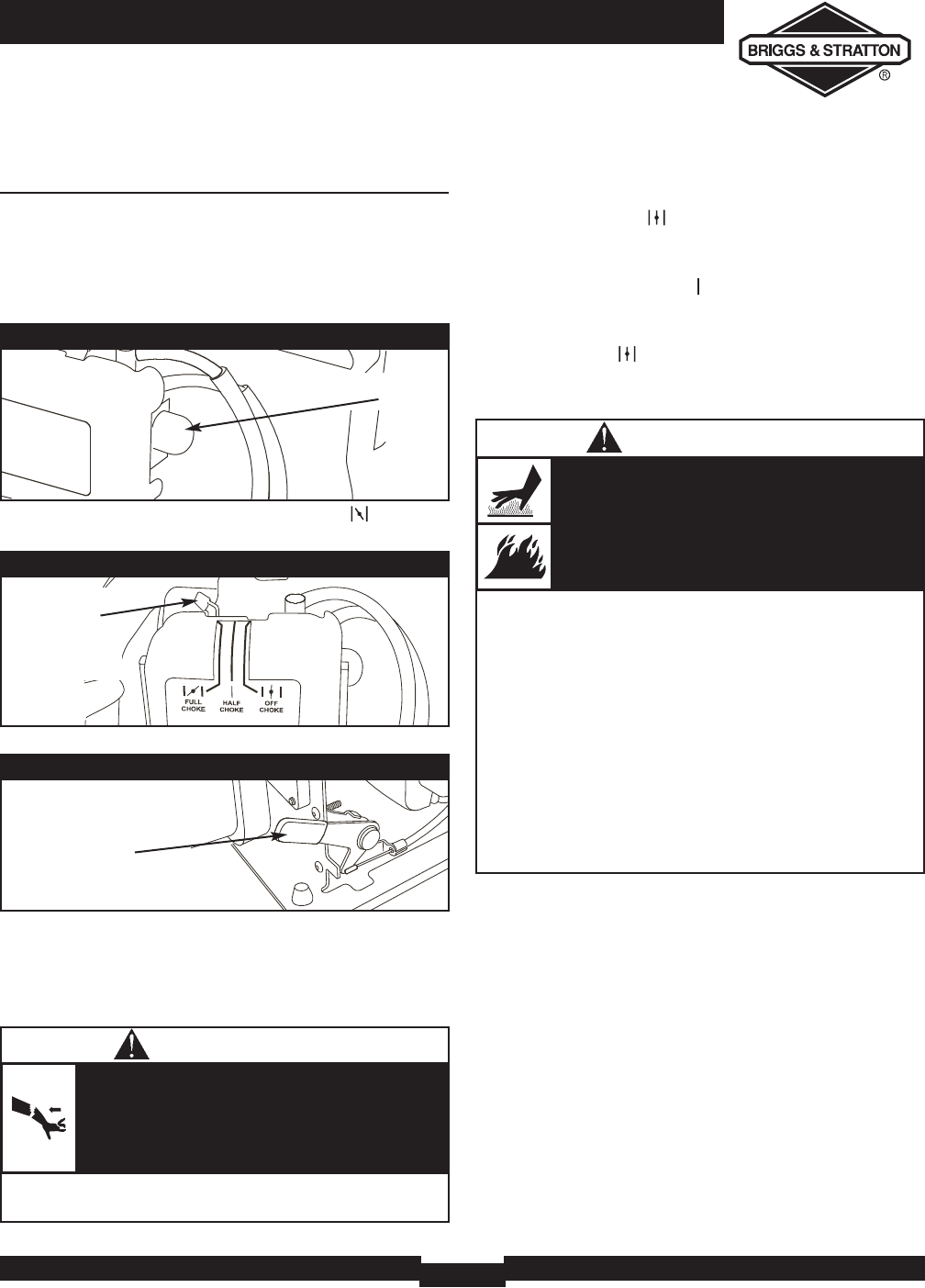

3. Move red choke lever to “Full Choke” ( ) position

(Figure 15).

4. Move throttle lever all the way up (Figure 16).

5. While firmly grasping pump carrying handle with

left hand, pull starter handle with right hand slowly

until slight resistance is felt. Then pull handle

rapidly to overcome compression, prevent kickback

and start engine.

IMPORTANT: If excessive fuel is present in the air/fuel

mixture causing a “flooded” condition, move choke

lever to “Off Choke” ( ) position and pull handle

repeatedly until engine starts.

6. Wait a maximum of 10 seconds, then move choke

lever to “Half Choke” ( ) position.

7. Run the engine at “Half Choke” for 20 seconds or

until unit accelerates smoothly. Move choke lever to

“Off Choke” ( ) position.

IMPORTANT: It may take a few minutes for water

pump to begin pumping water.

Pump output is controlled by adjusting engine speed.

Moving the throttle lever up will increase pump output,

and moving the throttle lever down will decrease pump

output.

• When starting engine, pull cord slowly until resistance is

felt and then pull rapidly to avoid kickback.

Rapid retraction of starter cord (kickback)

will pull hand and arm toward engine faster

than you can let go.

Broken bones, fractures, bruises or sprains

could result.

WARNING

Figure 16 — Throttle Lever

Throttle Lever

shown fully up

Figure 14 — Primer Bulb

Figure 15 — Choke Lever

Choke Lever

shown in

“Full Choke”

position

Primer Bulb

• DO NOT touch hot surfaces and avoid hot exhaust

gases.

• Allow equipment to cool before touching.

• Keep at least 5 ft. (152 cm) clearance on all sides of

water pump including overhead.

• Code of Federal Regulation (CFR) Title 36 Parks,

Forests, and Public Property require equipment powered

by an internal combustion engine to have a spark

arrester, maintained in effective working order, complying

to USDA Forest service standard 5100-1C or later

revision. In the State of California a spark arrester is

required under section 4442 of the California Public

resources code. Other states may have similar laws.

Running engines produce heat. Temperature

of muffler and nearby areas can reach or

exceed 150°F (65°C).

Severe burns can occur on contact.

Exhaust heat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

WARNING