4-1

SECTION IV

TROUBLESHOOTING

4-1 LEAKAGE

Analysis of general operational experience with diffusion pumps indicates that certain locations are

more prone to the incidence of leaks. The following locations should be checked first if leakage is the

suspected cause of poor system performance.

a. Inlet and foreline connections.

b. Drain and fill plugs.

c. Other compression fittings, such as high-vacuum gauges in the system.

d. Threaded connections, such as a foreline gauge.

4-2 OUTGASSING

High-vacuum systems, even without external leakage, can have high gas loads due to outgassing

from internal surfaces or processes. The pressure in the system is a result of gas load divided by

pumping speed (p = Q/S). If the gas load (Q) exceeds the maximum throughput capability of the diffu-

sion pump, the diffusion pump will not function and the pumping action will essentially be due to the

mechanical backing pump.

To estimate the gas load, isolate the system from all pumps after evacuation and measure the rate of

pressure increase. The gas load can be estimated as follows:

V x ∆P

Q=

______

∆t

where V is the isolated volume, ∆P is the pressure rise, and ∆t time period of measurement.

4-3 POOR PUMP OR SYSTEM PERFORMANCE

Before proceeding with a program of step-by-step troubleshooting, check the performance and accu-

racy of the vacuum gauges used on the system. Table 4-1 shows common faults, and lists the proba-

ble cause and corrective actions to correct for poor performance.

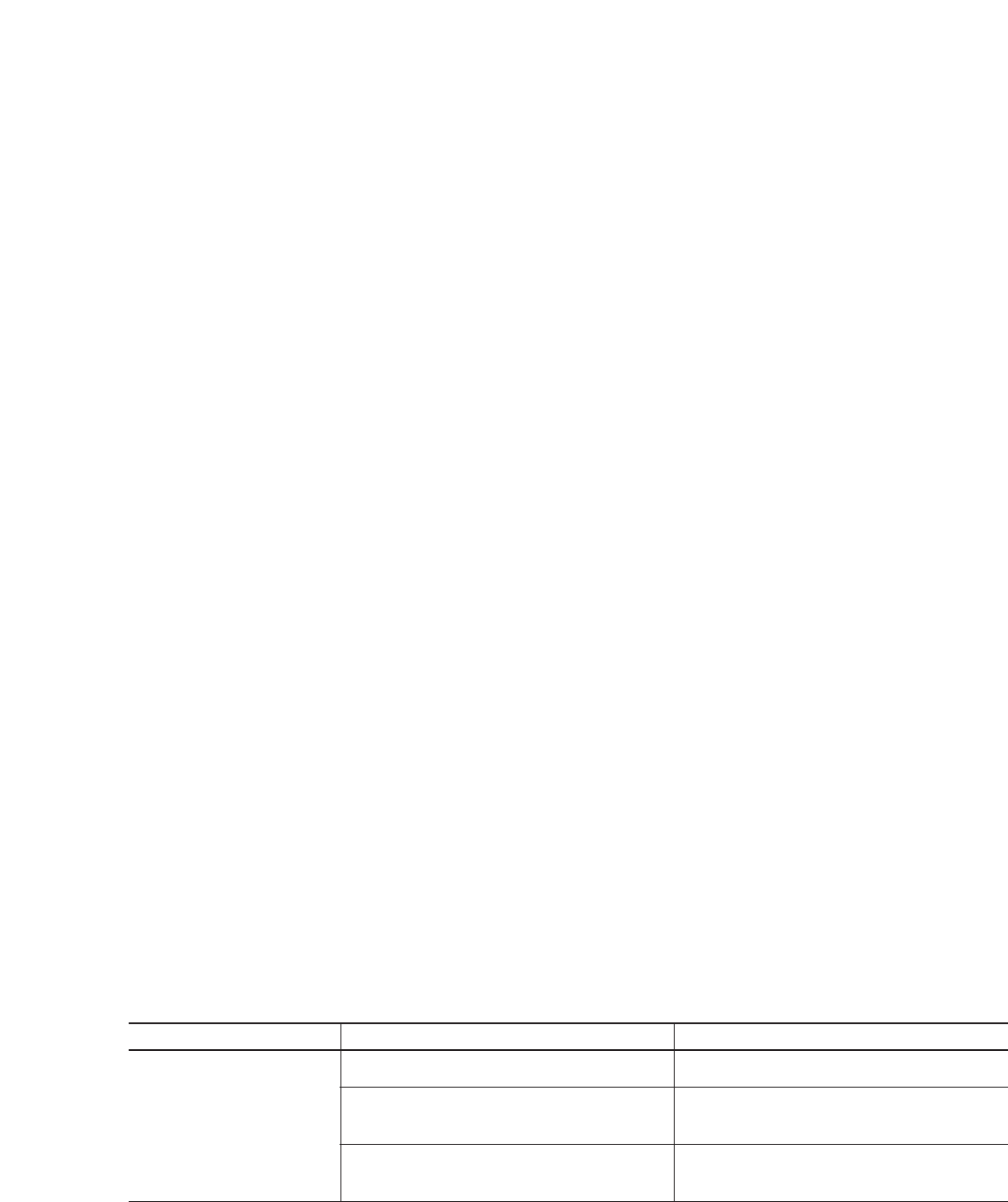

Table 4-1 Troubleshooting

Fault Probable Cause Corrective Action

Leaks in system, virtual or real Locate and repair.

High process gas load Measure gas load, eliminate

cause.

System dirty Clean system to reduce

outgassing.