16

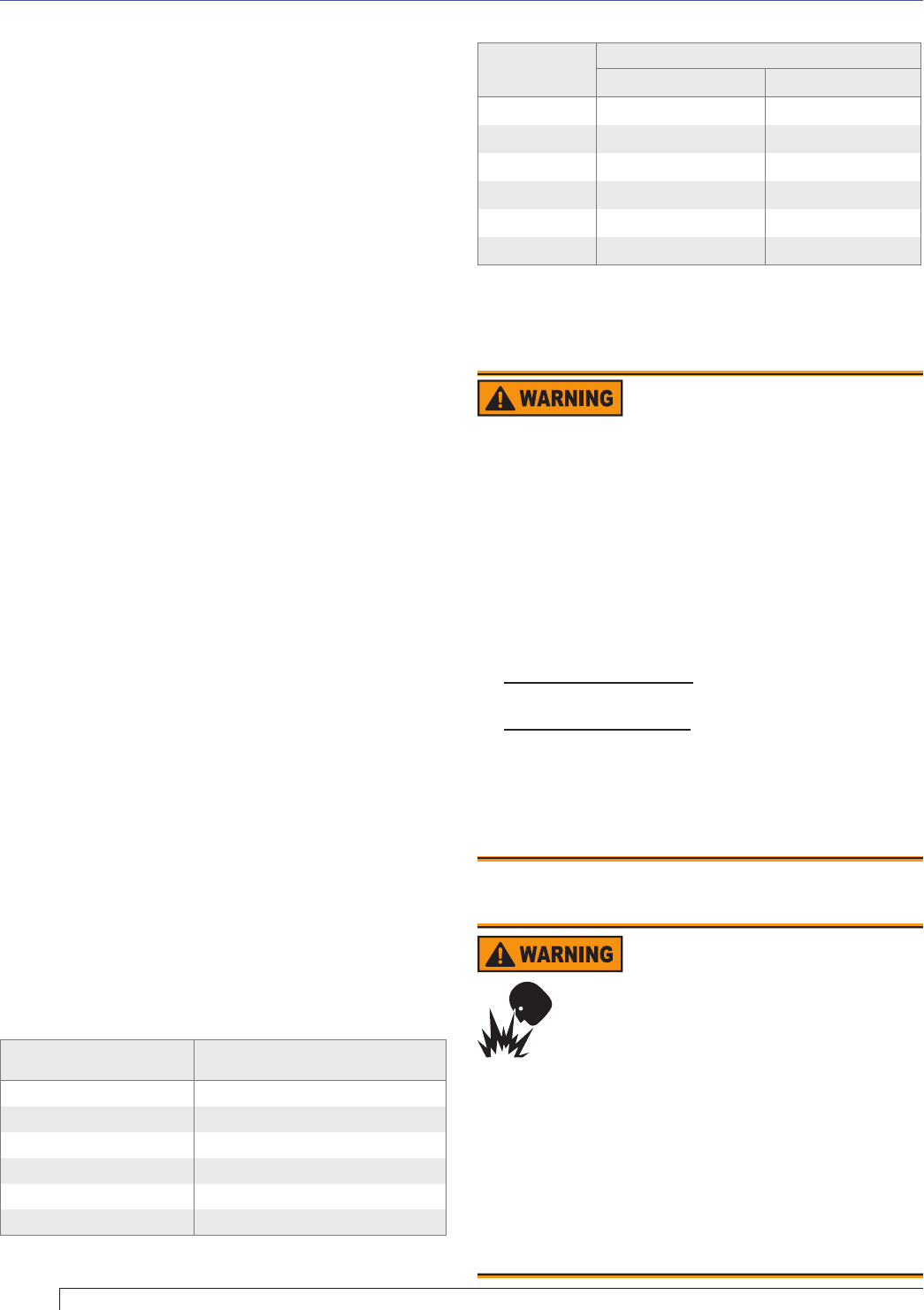

Table 5 - Initial indicator adjustment plate

settings (head position)

Approximate adjusting

plate setting

Firing rate, gph

0 1.65

1 1.75

3 2.00

4 2.50

5 3.00

6 3.50

Note: These settings are approximate, and can vary depending on

actual job conditions and overfi re pressure.

Section: Start the Burner

Table 6 - Initial air shutter and band settings

Firing rate,

gph

Approximate air settings

Shutter Band

1.65 5 0

1.75 10 2

2.00 10 4

2.50 10 5

3.00 10 6

3.50 10 8

Note: These settings are approximate, and can vary depending on

actual job conditions and overfi re pressure.

Appliance has been fi lled with water (boilers) and

controls have been operationally checked.

Burner has been installed in accordance with appliance

manufacturer’s instructions (when available).

Also refer to appliance manufacturer’s instructions

(when available) for start-up procedures.

Initial head position

(Reference Figure 8)

The indicator plate assembly markings correspond

to head position settings.

Loosen the fastener (Figure 8, item d) and slide the

indicator plate until the number on the indicator plate

corresponds to the initial head setting listed in Table

5, for the desired fi ring rate.

When the head position has been set, tighten the

fastener and the spline nut.

Initial air settings

(Reference Table 6)

Loosen the air band and shutter, and adjust to the

approximate fi ring rate settings given in Table 6.

These initial settings should be adequate for starting the

burner. Once the burner is in operation, the air settings

will be adjusted for best performance as discussed later

in this manual.

Follow the procedures described later in this manual for

fi ne-tuning the air settings.

Set appliance limit controls

Set the appliance limit controls in accordance with the

appliance manufacturer’s recommendations.

Prepare the fuel unit for air venting

To vent air from one-pipe oil systems, attach a clear

hose to the pump air bleed valve (fi gure 10 & 11) on the

fuel unit. Provide a container to catch the oil. Loosen the

pump air bleed valve.

Vent the air as described in the next section under Start

the burner.

□

□

□

○

○

○

Start the Burner

Explosion and Fire Hazard

Failure to follow these instructions could lead to

equipment malfunction and result in heavy smoke

emission, soot-up, hot gas puff-back, fi re and

asphyxiation hazards.

Do not attempt to start the burner when excess oil has

accumulated in the appliance, the appliance is full of

vapor, or when the combustion chamber is very hot.

Do not attempt to re-establish fl ame with the burner

running if the fl ame becomes extinguished during

start-up, venting, or adjustment.

Vapor-Filled Appliance: Allow the unit to cool off and

all vapors to dissipate before attempting another start.

Oil-Flooded Appliance: Shut off the electrical power

and the oil supply to the burner and then clear all

accumulated oil before continuing.

If the condition still appears unsafe, contact the Fire

Department. Carefully follow their directions.

Keep a fi re extinguisher nearby and ready for use.

y

y

y

y

y

y

Hot Gas Puff-back and

Heavy Smoke Hazard

Failure to bleed the pump properly could

result in unstable combustion, hot gas

puff-back and heavy smoke.

Do not allow oil to intermittently spray into a hot

combustion chamber while bleeding.

Install a gauge in the nozzle discharge port tubing or

fully open the pump bleed valve to prevent oil spray

from accumulating in the combustion chamber when

venting air from the fuel pump.

Ensure that all bubbles and froth are purged from

the oil supply system before tightening the pump air

bleed valve.

y

y

y

Starting the burner and venting air