10

Burner fuel fl ow

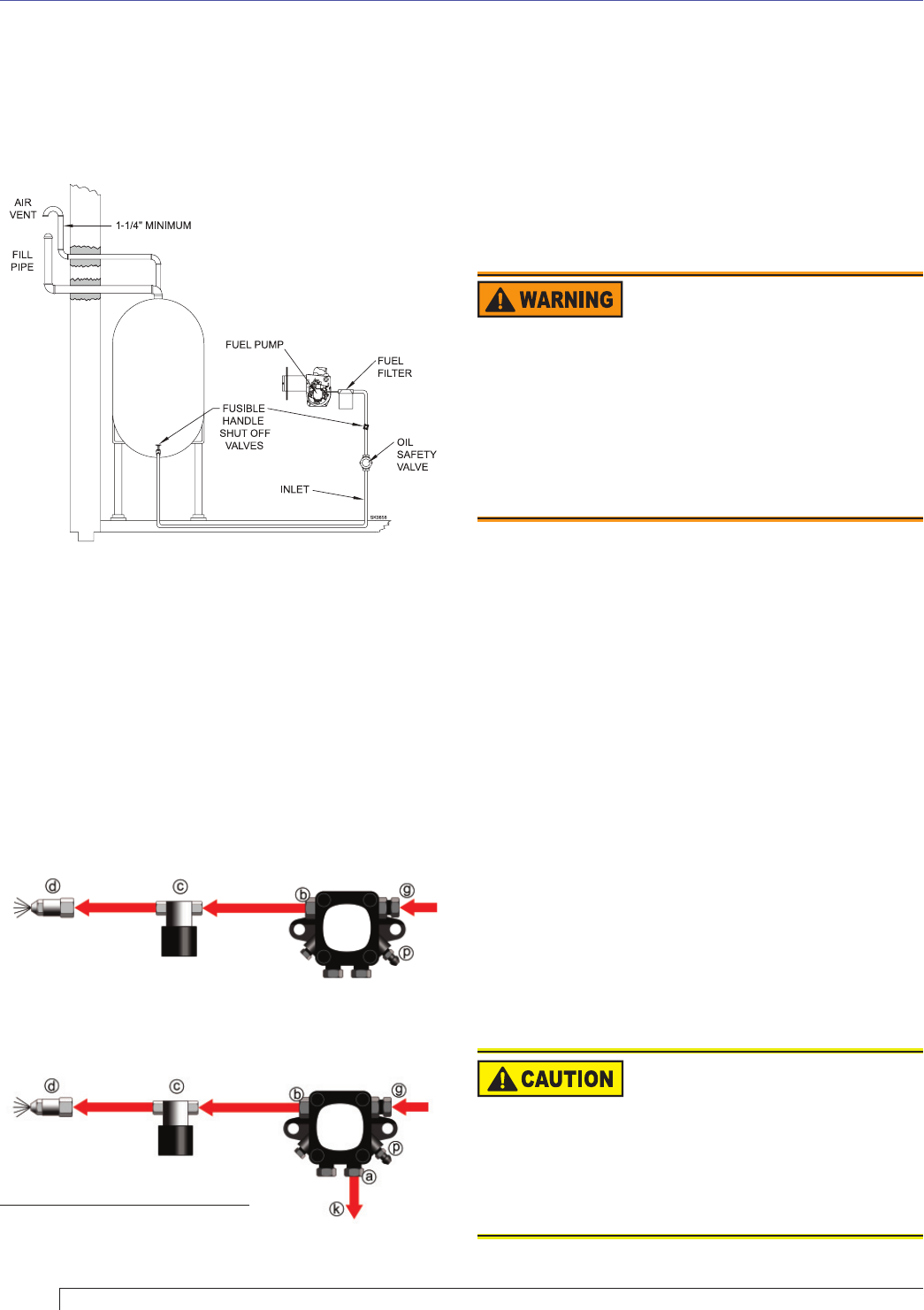

One-pipe systems – See Figure 10 for the fuel fl ow path.

Oil supply connects to one of the fuel unit inlet ports.

Two-pipe systems – See Figure 11 for the fuel fl ow paths

for two-pipe oil systems.

Oil supply connects to one of the fuel unit inlet ports. Oil

return connects to the fuel unit return port. (Install the by-

pass plug in the fuel unit for two-pipe systems.)

Nozzle pressure – The fuel unit nozzle port pressure

is factory set at 140 psig. Some original equipment

○

○

○

○

○

manufacturer burner applications may call for a lower

pressure to obtain a required fi ring rate. Do not change

this pressure unless directed to do so by the appliance

manufacturer.

125-200 psig

125-200 psig

3503

125-200 psig

125-200 psig

3502

Figure 10 - One-pipe oil fl ow (A pump)

Wire the Burner

Electrical Shock Hazard

Electrical shock can cause severe personal injury or death.

Disconnect electrical power before installing or

servicing the burner.

Provide ground wiring to the burner, metal control

enclosures and accessories. (This may also be

required to aid proper control system operation)

Perform all wiring in compliance with the National

Electric Code ANSI/NFPA 70 (Canada CSA C22.1).

y

y

y

Legend

a Return port

b Nozzle port

c Oil valve

d Nozzle & adapter

g Inlet port

k Return line to oil tank

p Air bleed valve

Figure 11 - Two-pipe oil fl ow (A or B pumps)

Figure 9 – Inside Tank Gravity Feed System

Install two high-quality shut-off valves in accessible

locations on the oil supply line. Locate one valve

close to the tank. Locate the other valve close to the

burner, upstream of the fuel fi lter.

○

Section: Wire the Burner

Incorrect Wiring Will

Result in Improper Control

Operation

GeniSys wiring label colors may not match the wire

colors of the burner or other manufacturers’ controls.

The GeniSys Control should be wired according to

the appliance manufacturer’s instructions.

y

y

Install the burner and all wiring in accordance with the

National Electrical Code and all applicable local codes

or requirements. In Canada, comply with the Canadian

Electrical Code, Part 1.

Wire the burner in compliance with all instructions

provided by the appliance manufacturer. Verify operation

of all controls in accordance with the appliance

manufacturer’s guidelines.

See Figure 13a or 13b for a typical wiring diagram with

the 7505 oil primary, for reference purposes only. See

Figure 14 for a typical wiring diagram with the R7184 oil

primary, for reference purposes only.

The 7505 primary control with valve-on delay (pre-

time) and burner motor-off delay (post time) requires

a constant 120 volts AC power source supplied to the

BLACK wire on the control. The RED wire goes to the

appliance limit circuit. Please note that other control

manufacturers may use different wire colors for power

and limit connections.

OIL

TANK