9

24 Vdc SDC Burner Manual

Section: Drive Component Maintenance

Drive Component

Maintenance

A. Motor, Blower Wheel, & Coupling

Replacement

The motor will require replacement if the proper voltage is

measured at the motor input, and the motor will either not

run, or the current draw with a free running pump exceeds

10% of the rated current.

To replace the burner motor, coupling and/or blower wheel

perform the following steps.

Before servicing, turn off and/or disconnect all power

to the burner.

Disconnect the burner motor wires.

Remove the bolts securing the motor to the burner

housing.

Remove the motor, coupling, and blower wheel.

Loosen the set screw on the blower wheel to slide

the existing wheel off the shaft.

Slide the new blower wheel onto the old shaft (after

thoroughly cleaning housing) and/or slide the old

blower wheel onto the new motor shaft.

When replacing the blower wheel, verify the wheel

is centered between the two sides of the burner

housing as shown.

Rotate the blower wheel until the set screw is

centered on the fl at of the motor shaft. Tighten the

set screw to secure the wheel.

Slide the motor coupling on the motor shaft then

install the motor on the burner housing. Insure that

the motor coupling fi ts between the motor shaft and

the pump shaft inside the housing. Tighten the motor

retaining screws. Reconnect the wires.

Restore power, start the burner and perform the

combustion test described previously in this manual.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

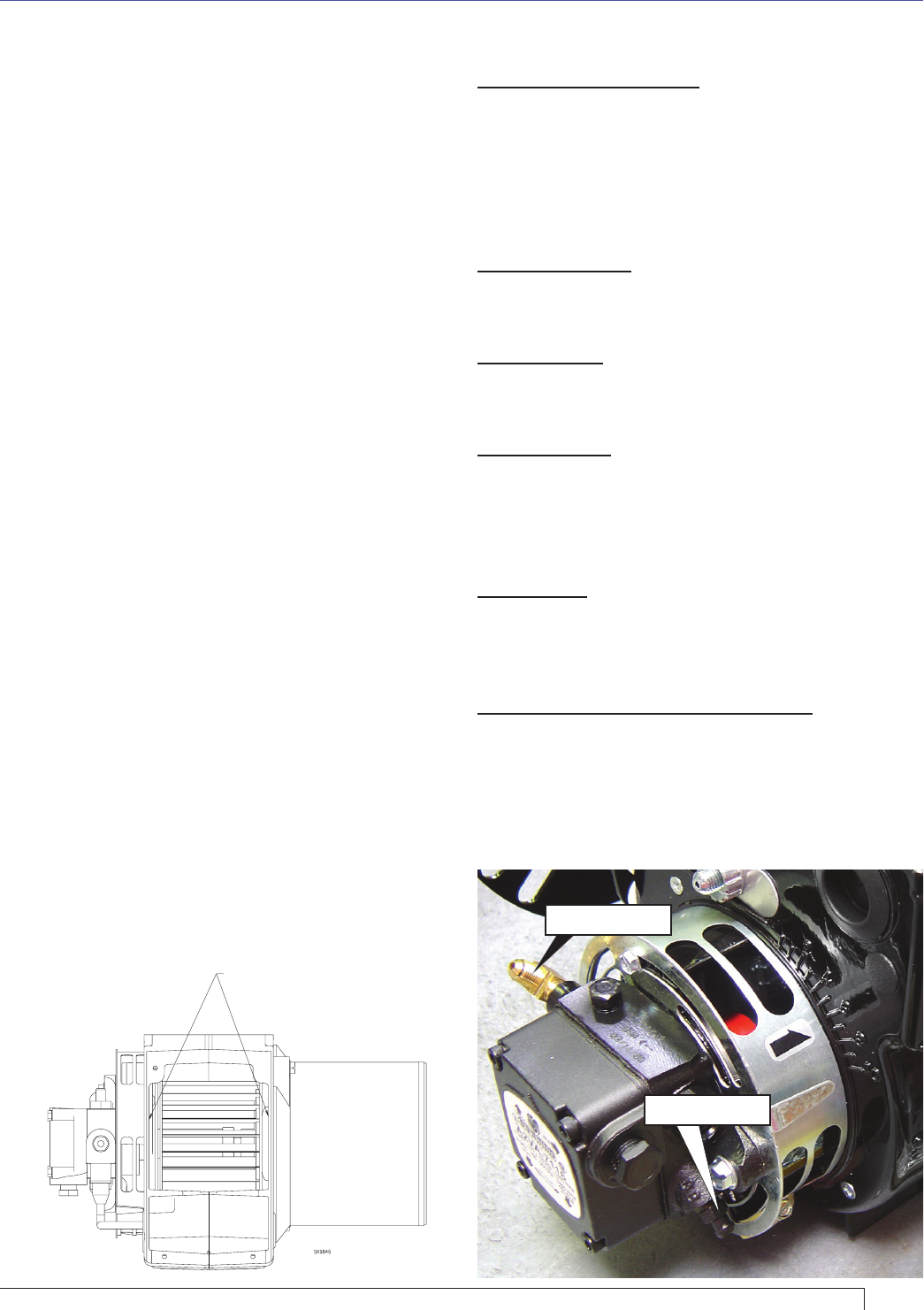

Figure 7. – Blower Wheel

CENTER WHEEL FOR EQUAL

DISTANCE FROM HOUSING SIDES

B. Pump Maintenance

General Pump Information

Important information - Long or oversized inlet lines may

require the pump to operate dry during initial bleeding period.

In such cases, the priming may be assisted by injecting fuel

oil in the pump gear set. Under lift conditions, lines and fi ttings

must be air tight. To assure this, “Pipe Dope” may be applied

to both the used and unused inlet and return fi ttings. Do NOT

use Tefl on tape or compression fi ttings.

Mounting Position

Beckett CleanCut pump may be mounted in any position

(except upside-down in a single pipe installation).

Vacuum Check

A Vacuum Gauge may be installed in either of the 1/4”

NPT inlet ports.

Pressure Check

Use the nozzle port when performing a pressure check.

If the bleed port is used, the reading on the gauge should

be approximately 5 psig higher than the pressure reading

on the nozzle port. See Figure 8.

Cutoff Check

To check cutoff pressure dead head a pressure gauge in the

nozzle port. Run the burner for a short period of time. Shut the

burner off. The pressure will drop and hold above zero.

Pressurized or gravity feed installations

These installations must not exceed 3 psig on inlet line or

return line at the pump per NFPA 31. A pressure greater

than 10 psig may cause damage to the shaft seal.

Figure 8. – Oil Supply Components

Bleed Port

Nozzle Port