13

24 Vdc SDC Burner Manual

Section: Troubleshooting

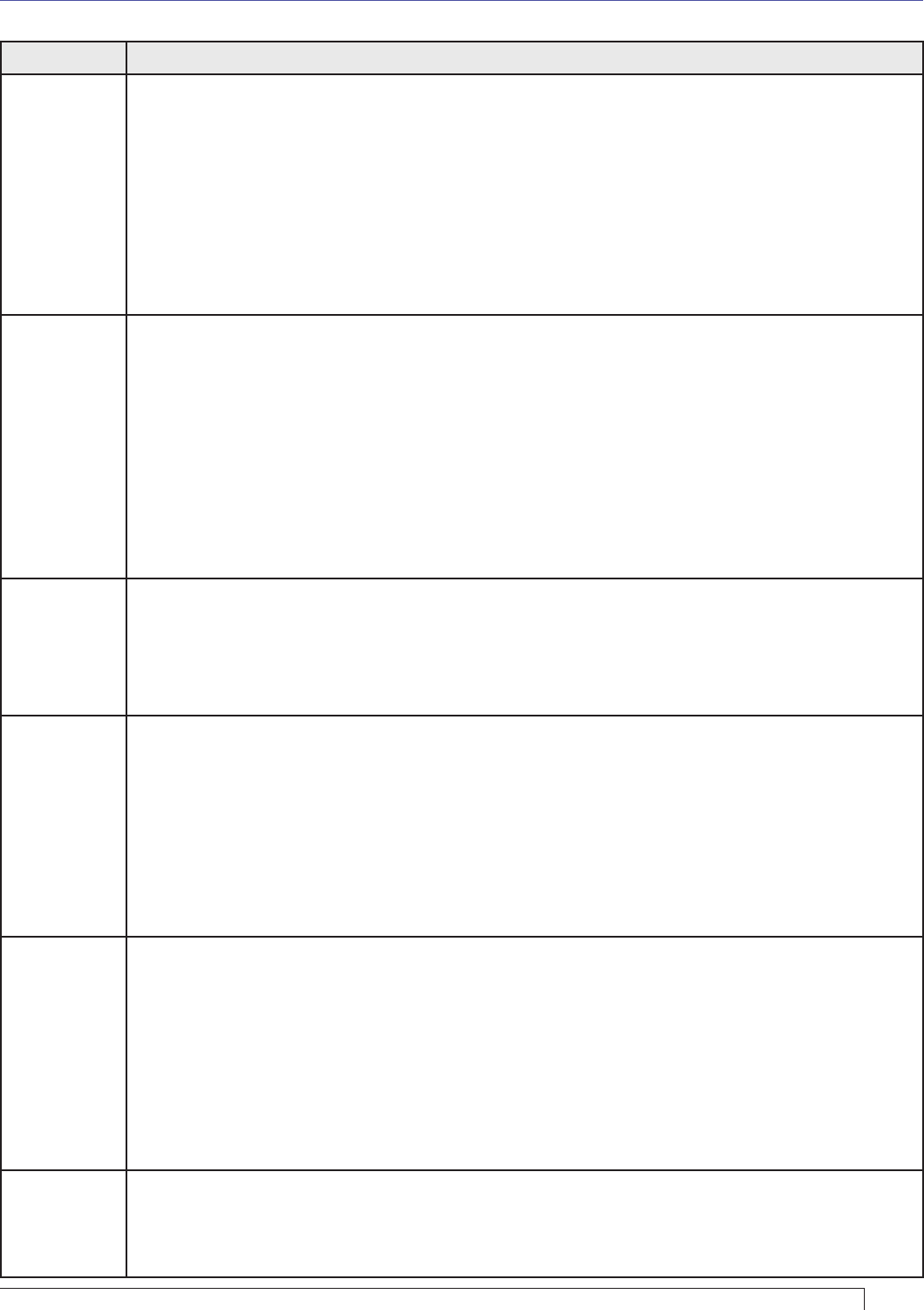

Table 3. Troubleshooting Chart

Symptom Possible Cause

Oil Not

Igniting

If the burner is not igniting, the burner motor, drive coupling, and oil pump are operating and oil is

fl owing to the nozzle through the solenoid valve, check the following possibilities.

Check the air shutter adjustment. If the air shutter is opened too far, the fl ow of air may prevent the arc from

reaching the oil spray. This may appear as a white vapor exhaust from the heater. [Refer to section “Start

up burner and set combustion”]

The ignition system may have failed to supply an adequate arc to ignite the oil. Check the battery and

charging system to insure a continuous supply of 21.8 to 28 volts DC (15 amps). [Refer to section

“Nozzle Assembly Maintenance”]

Check the electrodes for wear and damage. Insure that the electrodes are adjusted properly. [Refer to

section “Nozzle Assembly Maintenance”]

1.

2.

3.

No Flame

If there is no fl ame, the burner motor and igniter operate continuously and the oil solenoid valve is

functional, check the following possibilities.

Check for a plugged oil nozzle. [Refer to section 3]

If the coil on the solenoid valve is actuating, insure that the valve is opening or closing properly. [Refer to

section “Fuel Supply”]

Check for suffi cient fuel pressure. Pressure is 100 psig with valve energized, unless otherwise noted.

[Refer to section “Drive Component Maintenance”]

Check the pump pressure. Check for air in fuel lines.

Check burner for broken motor coupling. If the coupling is broken check pump rotation prior to replacing the

coupling.

[Refer to section “Drive Component Maintenance”]

Check for contaminated fuel and/or partially plugged fuel fi lter. [Refer to section “Fuel Supply”]

1.

2.

3.

4.

5.

6.

Motor Not

Operating

If the blower motor is not operating, check the following possibilities.

Check voltage at the motor to insure that switches and relays, in line with the motor, are operating properly.

[Refer to section “Burner Wiring”]

Check pump and motor shaft operation. They should work freely without binding. [Refer to section “Drive

Component Maintenance”]

1.

2.

No Oil Spray

If the blower motor is operating, there is fuel in the tank, but oil does not spray out the end of the

nozzle, check the following possibilities.

Check for a broken or stripped coupling between the pump and the motor. [Refer to section “Drive

Component Maintenance”]

Check the pump output for oil. [Refer to section “Drive Component Maintenance”]

Check operation of the oil valve. [Refer to section “Drive Component Maintenance”]

Check for a plugged nozzle. [Refer to section “Nozzle Assembly Maintenance”]

Check for air in the oil line. [Refer to section “Nozzle Assembly Maintenance”]

Check for fuel contamination or plugged fi lter. [Refer to section “Nozzle Assembly Maintenance”]

1.

2.

3.

4.

5.

6.

Fluctuating

or No Pump

Pressure

If the pump pressure, as determined by a pressure gauge, is erratic or does not exist, check the

following possibilities.

Check motor rotational speed. Low rpm can cause erratic or no pump pressure. [Refer to section “Drive

Component Maintenance”]

Check for a broken or worn motor coupling. [Refer to section “Drive Component Maintenance”]

Check that the pump turns freely. [Refer to section “Drive Component Maintenance”]

Check for air leaks in the lines. [Refer to section “Fuel Supply”]

Check for oil froth at the bleed point. [Refer to section “Fuel Supply”]

Check voltage at the motor. [Refer to section voltage rating on nameplate]

Check for fuel contamination or partially plugged fi lter.

1.

2.

3.

4.

5.

6.

7.

Slow Motor

Rotation

If the blower motor is not operating at the rpm’s listed on the nameplate, check the following.

Check the supply voltage to the motor. [Refer to section voltage rating on nameplate]

Check for free operation of the motor shaft and pump assembly. [Refer to section “Drive Component

Maintenance”]

1.

2.