SECTION 11

Working with the Fault Screen

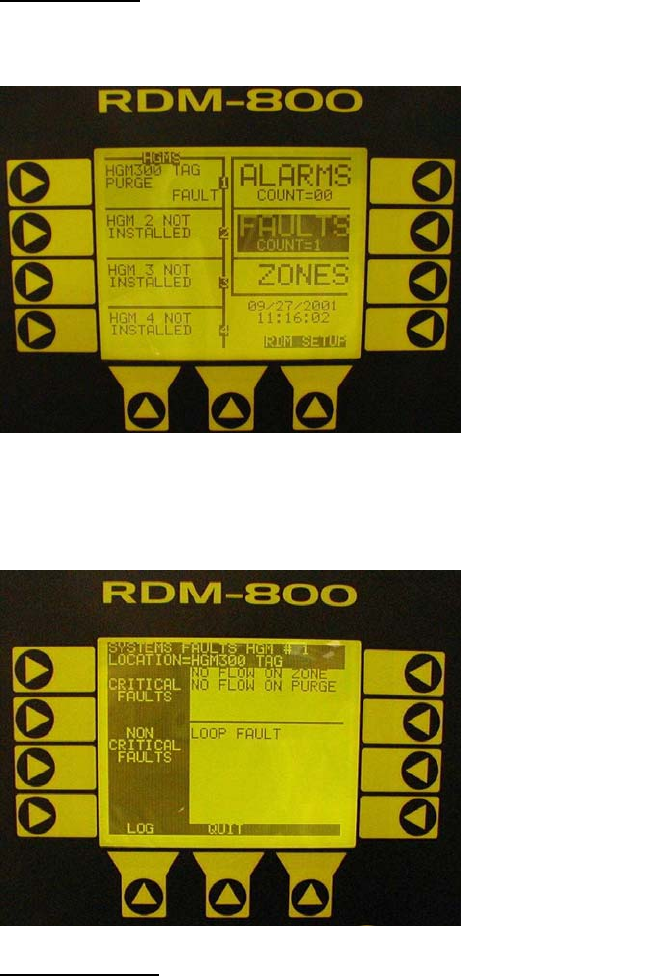

From the SYSTEM SCREEN press the button adjacent to FAULT. This takes you to the FAULT

SCREEN. The information displayed on this screen is broken onto two categories – CRITICAL FAULTS

and NON CRITICAL FAULTS.

Fault Screen

Critical Faults

• NO FLOW ON ZONE – Go to SYSTEM SCREEN, the to ZONES. The zone screen will display a “NO

FLOW” message in each individual zone affected. Check for a blockage in the air sample line or at

the line end filter. Once the blockage has been cleared, the HGM300 will return to normal operation

after the zone has been sampled. Note - This can take some several minutes since it is dependent

upon how many zones there are and their lengths. The HGM300 will clear the fault the next time it

polls the effected zone and the RDM800 will return to normal operation the next time that it polls the

HGM300.

• NO FLOW ON PURGE – Check the purge line for a blockage. Verify that the length of the purge line

and exhaust line do not exceed 300 feet in length.

• NO FLOW DETECTED – Check for proper pump operation. Check the water trap – drain if

necessary.

• CLIPPING FAULT – The detector voltage may be out of tolerance. Check the DIAGNOSTIC

SCREEN for the DET voltage, AVE voltage and ZERO voltage. Call the factory with this information

for farther instructions.

• REZERO VOLT TOL – The detector output voltage is out of tolerance. Check the DIAGNOSTIC

SCREEN as in item 4 and contact the factory for assistance.

21