4 Instruction 3015-4286

Suggested Location of Sampling Point

At the point of an ammonia gas leak the gas is nearly pure. As ammonia gas is dispersed into the air, the

gas molecules diffuse causing a dilution of the original concentration. The AGMSZ measures the gas

concentration at the point the sample is collected. Therefore, if the termination of the collection line is not

at the exact point of the gas leak, then the monitor will read a diluted mixture of ammonia gas and air.

It should be noted that when ammonia gas is cold it is heaver than air and settles below the leak point,

but as the gas warms to room temperature it becomes lighter than air and tends to collect above the leak

point. Consequently, the sampling point should ideally be located as close as possible to the source of a

potential leak. If this is impractical, then the alarm set points should be adjusted to compensate for the

dilution of the ammonia gas.

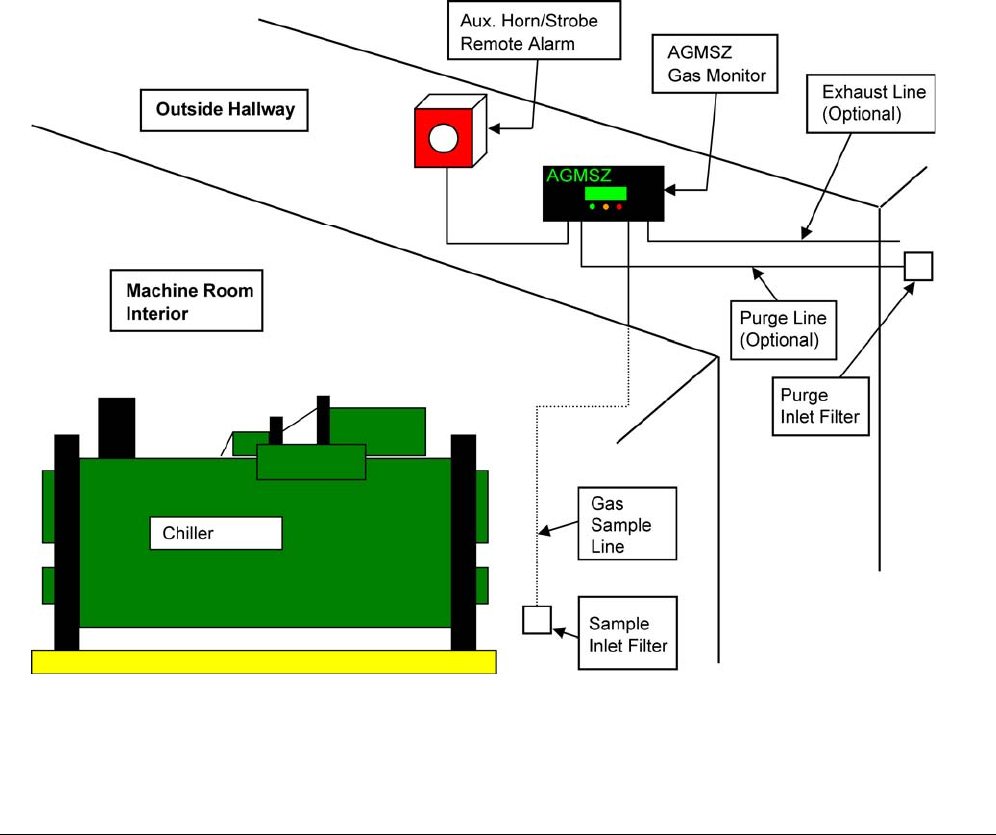

The AGMSZ should be mounted outside of the mechanical room or at least just inside of a door to the

room. This is the “split architecture design” for safety of the operator. The monitor should be readily

accessible for easy visual monitoring and servicing. The gas-sample line can be up to 50 ft (15.2 m) in

length. If the area around the monitor is not well ventilated, then an optional exhaust line and purge line

can be run to an outside location. The length of the exhaust line cannot exceed 50 ft (15.2 m), while the

length of the purge line cannot exceed 100 ft (30.4 m).

It may be necessary to perform a “smoke” test of the mechanical room to determine the best monitoring

point. The smoke test would provide the pattern of air currents present in the room.

AGMSZ Refrigerant Gas Leak Monitor Mechanical Room Placement