Instruction 3015-4286 7

Tubing Considerations

Use ¼" outside diameter (0.040" wall) flex tubing for all air lines (P/N 304-2742 or equivalent). The tubing

should be clean and free of moisture or other contaminants. The tubing should be cut cleanly with a sharp

knife and care should be taken not to distort the tubing end.

IMPORTANT! Due to the reactive nature of ammonia gas, it is important to use materials that will not

absorb the gas as it passes through the sampling system. The use of unauthorized tubing or any other

materials in the gas-sampling stream may lead to erroneously low readings.

All tubing bends should have a radius of no less than 5" to insure proper airflow. If kinks or obstructions

occur in the line the monitor may not function properly.

Connecting the Gas-Sample Line

Please refer to Section Suggested Location of Sampling Point (Page 4) to learn more about where to take

a gas sample.

The gas-sample line can be up to 50 ft (15.2 m) in length. The end of this line should be placed near the

potential leak source and positioned to reduce the possibility of mists, aerosols, oil, water, dust, or other

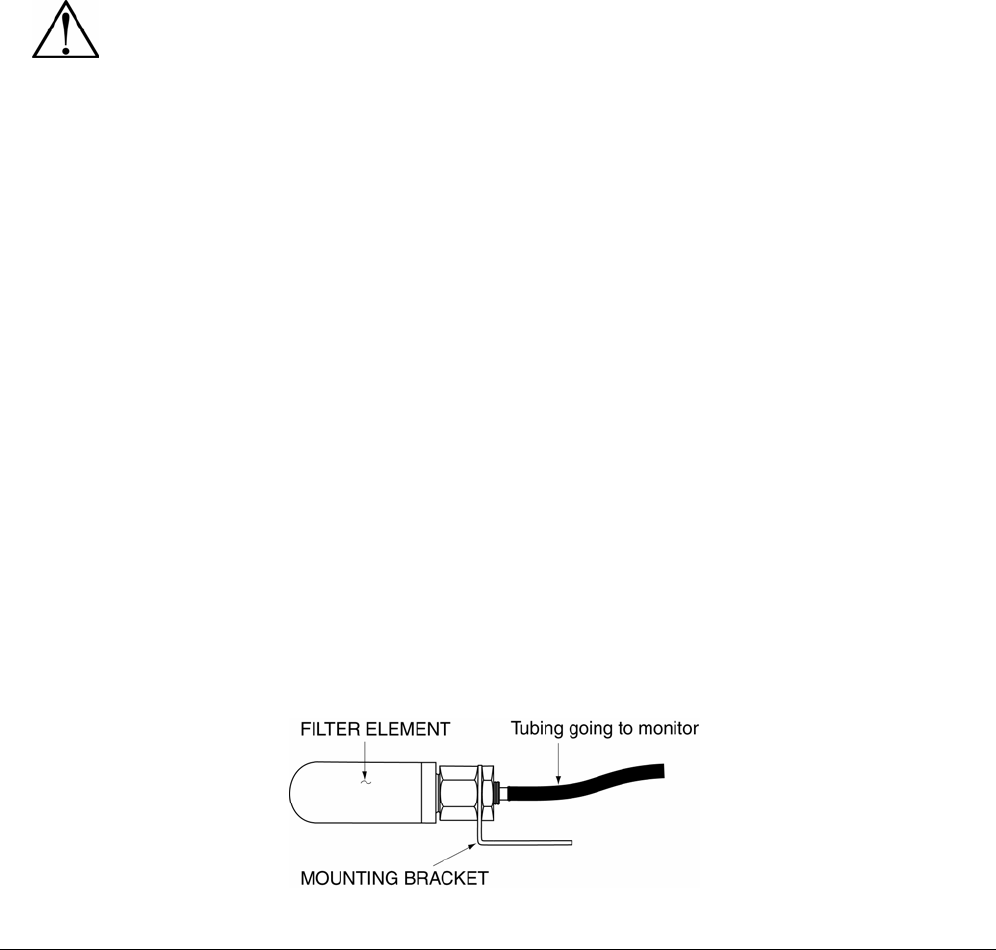

contaminates from being drawn into the monitor. For added protection, a termination filter (P/N 3015-3420)

supplied with the monitor must be attached to the end of this line.

CAUTION: The introduction of contaminants through the gas-sample line can result

in serious and permanent damage to the monitor.

Connecting the Purge Line

The purge line functions to bring fresh (zero) air into the monitor for the purpose of purging the detector

and setting its baseline zero reading. This purge line is required if the monitor is located in an area that

contains ammonia gas or other types of refrigerant.

The purge line can be up to 100 ft (30.4 m) in length. This line should terminate in an area known to

contain fresh air. To connect the purge line to the monitor, simply push the tubing into the Purge Air Inlet

Port. If the purge line terminates outside the building, position the tubing so that no water or moisture

can enter the line. For added protection from contaminates entering the monitor, a termination filter

(P/N 3015-3420) must be attached to the end of this line.

Connecting the Exhaust Line

The exhaust line functions to carry the exhausted gas sample away from the monitor, and is required if

the monitor is located in a confined, poorly ventilated area. If no purge line is used, it is a good idea to vent

the exhausted gas sample away from the monitor to prevent erroneous readings due to improper zeroing of

the detector.

The exhaust line can be up to 50 ft (15.2 m) in length. Ideally this line should terminate outdoors in a

location that is not exposed to the elements. Connect the exhaust line to the monitor by firmly pushing the

tubing onto the Gas Sample Exhaust Port’s barbed fitting. Ensure that no loops or dips are present that

could trap condensate. This is likely as outside air can be cooler than instrument. Note that the exhaust

line does not require a termination filter.

Termination Filter (P/N 3015-3420)