9

WATER HEATER ATTITUDE

There is a certain amount of variation permissible with regard

to the direction the water heater faces.

Standing in front of the water heater (gas control facing you), set

the 3” diameter elbow (slotted end) on the flue. This will give

you a better understanding of the relation of the vent assembly

to the opening in the wall and more importantly any possibly of

interference of venting and water piping.

The direction of the water heater can now be made. Also

consider the gas control valve to insure installation, lighting,

and maintenance accessibility are retained.

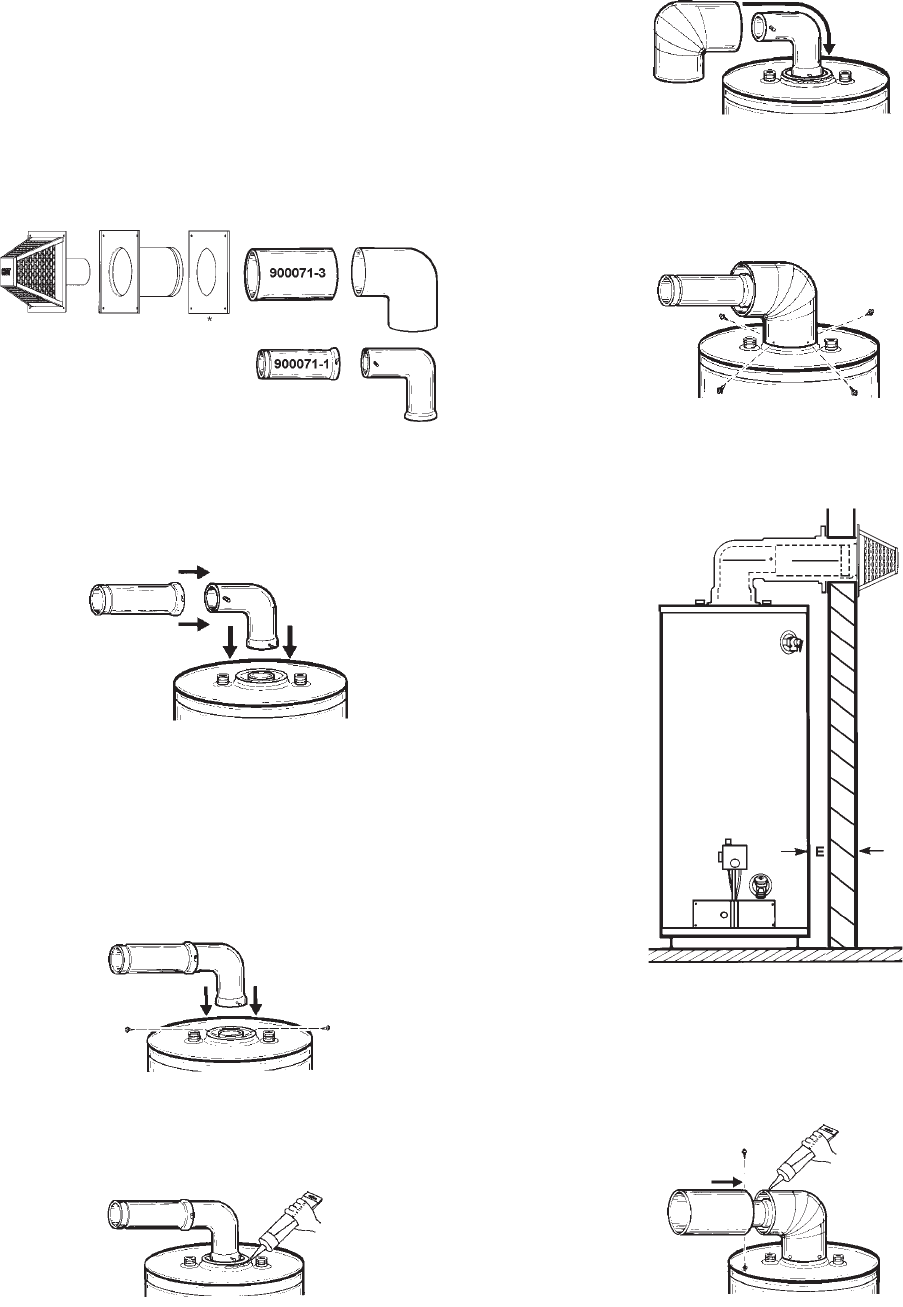

STANDARD VENT KIT INSTALLATION #1

FIGURE 14

The opening through the wall should be cut at this time. If it

hasn’t been, refer back to that section.

1. Lock the elbow to the straight 3” flue pipe. Set this assembly

in place on the end of the water heater’sflue collar.

FIGURE 15

2. Mark the flue collar at the slots in the elbow. Using a #22 drill

bit, drill holes into the flue collar at the two

slots and secure the elbow to the flue collar using the

screws provided.

NOTE: Make sure elbow is properly aligned to opening in

the outside wall.

FIGURE 16

3. Using the tube of sealant supplied, run an ample amount

around the oval flare of the jacket.

FIGURE 17

4. First remove the 3” horizontal extension from the elbow.

Starting with the long end (with four securing holes), place

the 6” diameter vent elbow over the 3” diameter elbow.

Bend the round end “oval” to fit the flared oval end of the

jacket top.

FIGURE 18

5. Making sure the 6” diameter elbow is centered around the

3” diameter flue, secure the 6” diameter vent pipe using

four sheet metal screws at the connection of the jacket top.

V

FIGURE 19

6. The standard vent kit includes a 6” diameter extension pipe

which is used when “E” dimension is over 6 1/2”.

FIGURE 20

7. If “E” is less than 6 1/2” move to next step.

If “E” dimension is over 6 1/2”, assemble the 6” diameter

extension pipe (crimped end) to the 6” diameter vent elbow

and secure using two sheet metal screws.

FIGURE 21

* Each part is stamped with a

part number.