21

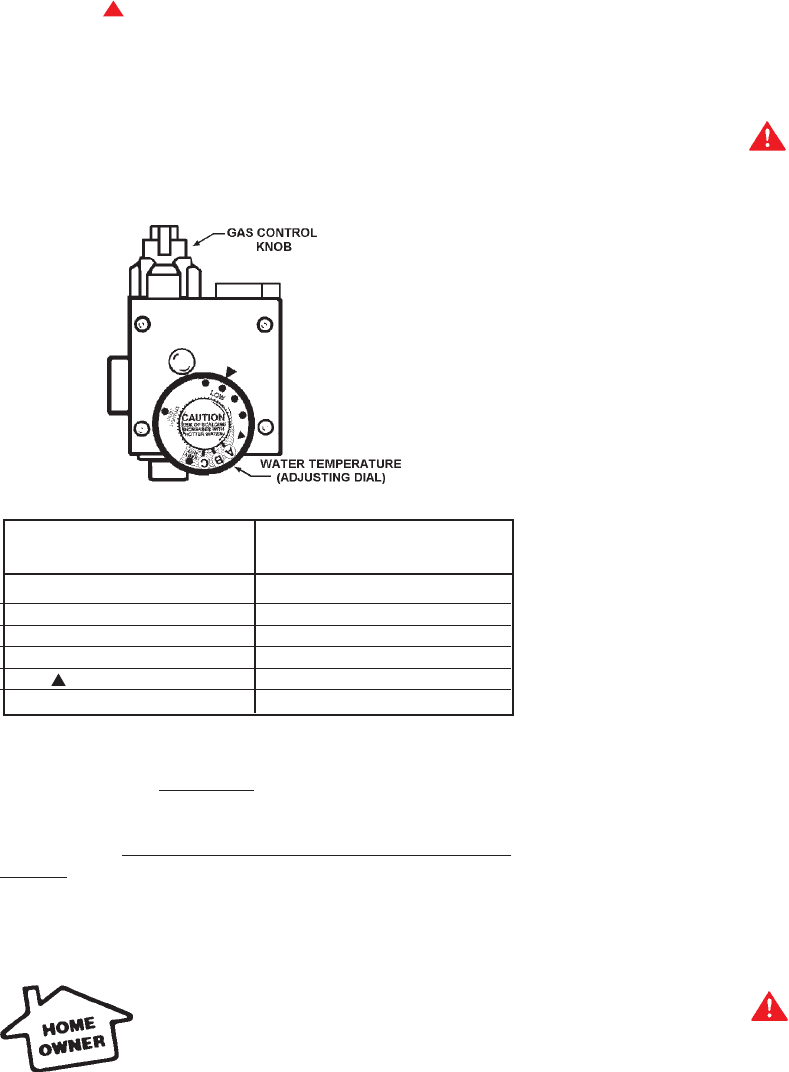

It is recommended that lower water temperatures be used to

avoid the risk of scalding. It is further recommended, in all

cases, that the water temperature dial, Figure 99, be set for the

lowest temperature which satisfies your hot water needs. This

will also provide the most energy efficient operation of the

water heater. The water temperature adjusting dial was factory

set at the lowest temperature; all the way clockwise to the

mechanical stop. Turning the dial counterclockwise increases

temperature and clockwise reduces temperature.

SETTING THE WATER HEATER TEMPERATURE AT 120°F

(APPROX. “ ” MARK ON FACE OF THERMOSTAT) WILL

REDUCE THE RISK OF SCALDS. Some states require

settings at specific lower temperatures.

Figure 99 shows the approximate water temperatures produced

at various thermostat dial settings. Short repeated heating cycles

caused by small hot water uses can cause temperatures at the

point of use to exceed the thermostat setting by up to 30°F. If you

experience this type of use you should consider using lower

temperature settings to reduce scald hazards.

Temperature Time to Produce 2nd & 3rd

Setting Degree Burns on Adult Skin

VERY HOT= approx. 160°F About 1/2 second

C = approx. 150°F About 1-1/2 seconds

B = approx. 140°F Less than 5 seconds

A = approx. 130°F About 30 seconds

= approx. 120°F More than 5 minutes

LOW = approx. 80°F

FIGURE 99

Valves for reducing point-of-use temperature by mixing cold and

hot water are available (See Fig. 2). Also available are

inexpensive devices that attach to faucets to limit hot water

temperatures.

Contact a licensed plumber or the local plumbing

authority.

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL

TO SHUT OFF, TURN OFF THE MAIN MANUAL GAS CONTROL

VALVE TO THE APPLIANCE (SEE FIGURE 1).

MAINTENANCE

FOR YOUR SAFETY AND SATISFACTORY OPERATION, IT IS

RECOMMENDED THAT THIS HEATER BE CHECKED ONCE A

YEAR BY A COMPETENT SERVICE PERSON.

USERS OF THIS APPLIANCE SHOULD BE AWARE THAT GAS

COMPONENTS WEAR OUT OVER A PERIOD OF TIME. THE

GAS CARRYING COMPONENTS OF THIS APPLIANCE

SHOULD BE INSPECTED FOR PROPER OPERATION

PERIODICALLY BY A QUALIFIED SERVICE TECHNICIAN.

PILOT AND MAIN BURNER

Check pilot and main burner every six months for proper flame

characteristics. This is done by removing door on heater, fig. 1.

The main burner should provide complete combustion of gas;

ignite rapidly; give reasonably quiet operation; cause no

excessive flame lifting from burner ports. Make sure that the

flow of combustion and ventilation air is not blocked.

If proper flame characteristics are not evident, check for

accumulation of lint or other foreign material that restricts or

blocks the air openings in the heater or burner.

WARNING

SOOT BUILD-UP INDICATES A PROBLEM THAT REQUIRES

CORRECTION BEFORE FURTHER USE. CONSULT WITH A

QUALIFIED SERVICE TECHNICIAN.

Should the main burner or burner air openings require

cleaning, turn the gas control knob to “OFF” position and allow

the burner to cool. Remove the burner and clean with a soft

brush. Clean main burner orifice with a suitable soft material.

HIGH TEMPERATURE LIMIT SWITCH

(Single-Use Type Energy Cut Off)

The thermostat has a built-in limit switch which will extinguish

the pilot light in case of excessive water temperatures. The

pilot cannot be relit until the entire thermostat (labeled as

single-use type) is replaced. It is important that a serviceman

be called to determine the reason for limit operation and thus

avoid repeated thermostat replacement. Lower the temperature

adjustment dial setting on the new control.

VENTING

HAVE VENTING SYSTEM CHECKED EVERY SIX MONTHS FOR

OBSTRUCTIONS AND/OR DETERIORATION IN VENT PIPING.

TEMPERATURE & PRESSURE RELIEF VALVE

At least once a year, the temperature and pressure relief valve,

fig. 1. must be checked to ensure that it is in operating

condition. Lift the lever at the top of the valve several times until

the valve seats properly and operates freely.

If water does not flow, remove the valve and inspect for

obstructions or corrosion. Have a qualified servicer replace

with a new valve of the recommended size as necessary. Do

not attempt to repair the valve, as this could result in improper

operation and a tank explosion. In areas with poor water

conditions, it may be necessary to inspect the T&P valve more

frequently.

WARNING

THE WATER PASSING OUT OF THE VALVE DURING THIS

CHECKING OPERATION MAY BE EXTREMELY HOT. AVOID

CONTACT AND DISCHARGE SAFELY TO PREVENT WATER

DAMAGE.

DRAINING

If the heater is to be shut off and exposed to freezing

temperatures, it must be drained. Water, if left in the tank and

allowed to freeze, will damage the heater.