2

FOREWORD

The design of models BTI-80 and 100 comply with the latest version of

ANSI Z21.10.3/CSA 4.3 as automatic storage or automatic circulating tank

type water heaters.

Installation diagrams are found in this manual. These diagrams will serve

to provide the installer with a reference for the materials and method of

piping necessary. It is highly essential that all water and gas piping be

installed as shown on the diagrams.

In addition to these instructions, the equipment shall be installed in

accordance with those installation regulations in force in the local area

where the installation is to be made. These shall be carefully followed in

all cases. Authorities having jurisdiction should be consulted before

installations are made.

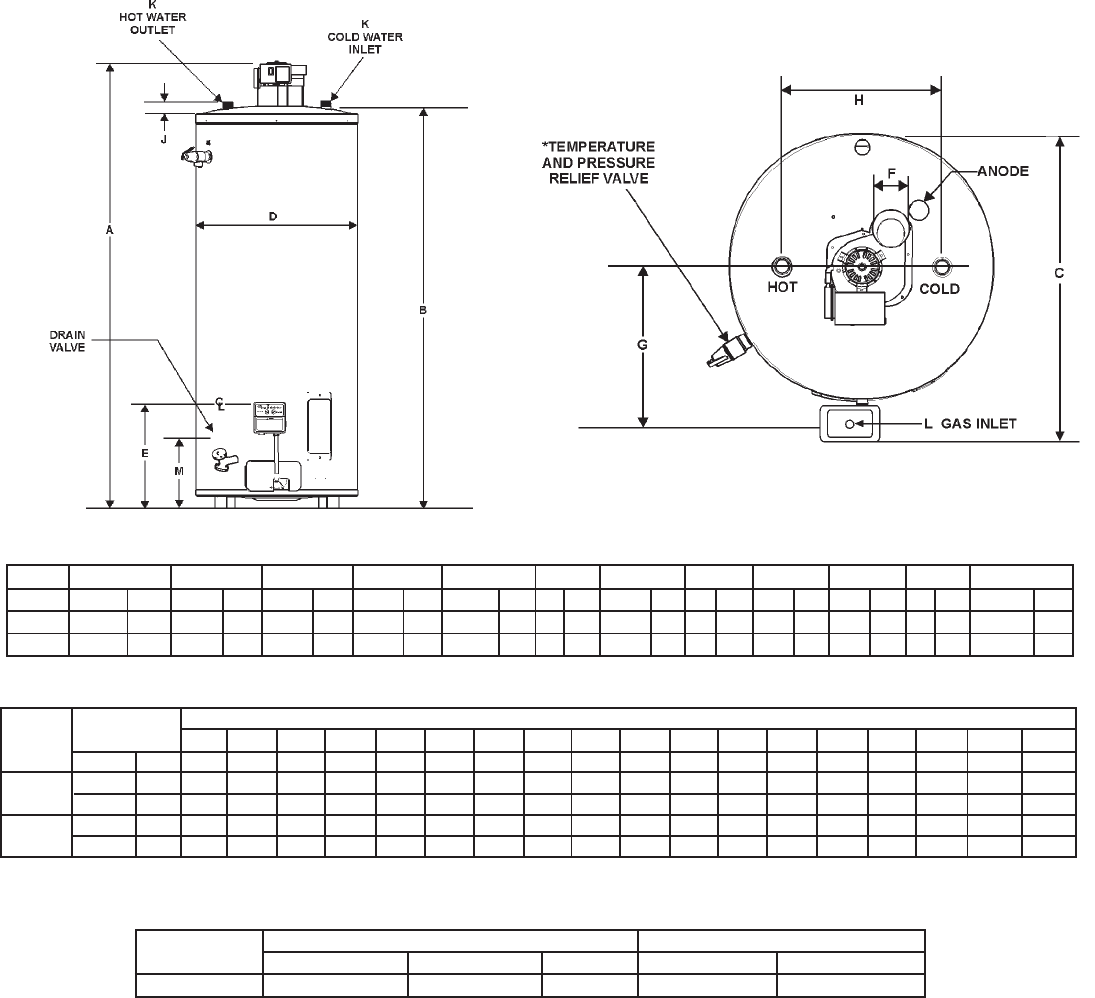

ROUGH-IN DIMENSIONS

FIGURE 1

The installation must conform to these instructions and the local code

authority having jurisdiction.

In the absence of local codes, the installation must comply with the following:

In the United States:

National Fuel Gas Code, ANSI Z223.1 / NFPA 54 and the National Electric

Code, NFPA 70;

In Canada:

Installation Code CAN/CSA B149.1-00 and the Canadian Electric Code CSA

C22.1.

These are available from Canadian Standards Association, 8501 East

Pleasant Valley Road, Cleveland, OH 44131 or National Fire Protection

Association, 1 Batterymarch Park, Quincy, MA 02269.

*INSTALL IN ACCORDANCE WITH LOCAL CODES

TOP VIEW

TABLE 1, DIMENSIONS

ABCDEFGHJKLM

MODEL In. mm In. mm In. mm In. mm In. mm In. mm In. mm In. mm In. mm In. mm In. mm In. mm

BTI-80 66 5/16 1684 58 1/2 1486 29 5/8 753 25 3/8 645 17 1/4 438 4 102 14 356 16 406 1 1/4 32 1 25 1/2 13 11 15/16 303

BTI-100 71 1/4 1810 66 1/2 1689 30 3/4 781 26 1/2 673 17 1/4 438 4 102 14 1/2 368 16 406 1 1/4 32 1 1/4 32 1/2 13 11 15/16 303

TABLE 3, GAS AND ELECTRICAL CHARACTERISTICS

Manifold Pressure Electrical Characteristics

MODEL Type of Gas Inches W.C. kPa Volts/Hz Amperes

BTI (80, 100) Natural Gas 3.5 0.87 120/60 <5

All Models:Maximum supply pressure = 14.0 in. W.C. (3.48 kPa)

Minimum supply pressure, Natural gas = 4.5 in. W.C. (1.12 kPa), Propane gas = 11.0 in. W.C. (2.74 kPa).

Minimum pressures must be maintained under both load and no load (static and dynamic) conditions.

TABLE 2, RECOVERY CAPACITIES (based on 80% thermal efficiency)

U.S. Gallons/Hr and Litres/Hr at TEMPERATURE RISE INDICATED

INPUT F° 30F° 36F° 40F° 50F° 54F° 60F° 70°F° 72F° 80F° 90F° 100F° 108F° 110F° 120F° 126F° 130F° 140F°

MODEL BTUH KW C° 17C° 20C° 23C° 28C° 30C° 33C° 39C° 40C° 44C° 50C° 56C° 60C° 61C° 67C° 70C° 72C° 78C°

BTI-80 76,500 GPH 247 206 185 148 137 124 106 103 93 82 74 68 67 62 59 57 53

22.4 LPH 931 779 700 560 518 469 401 389 352 310 280 257 253 234 223 215 200

BTI-100 90,000 GPH 291 242 218 175 162 145 125 121 109 97 87 81 79 73 69 67 62

26.4 LPH 1104 915 825 662 613 548 473 457 412 367 329 306 299 276 261 253 234

Recovery capacity based on 80% thermal efficiency.