13

BLOWER MAINTENANCE

For safety and satisfactory operation it is recommended that the blower be

checked once a year by a competent service person.

1. MOTOR - The motor is factory oiled and sealed and requires no further

maintenance.

2. WHEEL - Wheel must be clean of soot, ash or any other coating which

inhibits either rotation or air flow. Remove all foreign material from

vent system.

3. The pressure switch is inside the blower control box and is connected

to the blower housing with a tube. This tubing should be soft and

pliable and show no sign of deterioration.

RELIEF VALVE

At least once a year the temperature and pressure relief valve should be

checked to ensure that it is in operating condition. (During manual operation

of this valve, avoid any contact with hot water and take preventive steps for

water damage). Lift the lever at the top of the valve several times until the

valve seats properly and operates freely.

WARNING

THE WATER PASSING OUT OF THE VALVE DURING THIS CHECKING

OPERATION MAY BE EXTREMELY HOT. AVOID CONTACT AND

DISCHARGE SAFELY TO PREVENT WATER DAMAGE.

If the temperature and pressure relief valve on the heater discharges

periodically or continuously, a problem exists. This may be due to unusually

high water temperatures or pressures in the system, or to a faulty relief

valve. Contact your dealer or a qualified service technician to find the

cause of the problem and to correct it. This may also be due to thermal

expansion in a closed water supply system. Contact the water supplier or

local plumbing inspector on how to correct this situation. DO NOT PLUG

THE TEMPERATURE AND PRESSURE RELIEF VALVE.

WARNING

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL TO SHUT

OFF, TURN OFF THE MANUAL GAS CONTROL VALVE TO THE

APPLIANCE.

HOT WATER ODOR

On occasion, hot water may develop a strong odor. If this occurs drain the

heater completely, flush thoroughly, and refill. If the problem persists,

chlorination of the heater and replacement of the factory installed magnesium

anode with aluminum anode may correct the condition.

Occasionally water softener companies recommend removal of heater

anodes for odor reasons.

CAUTION

Unauthorized removal of heater anode will void the warranty. Replace the

anode as necessary to maintain corrosion protection. For further information

contact your dealer.

WINTER PROTECTION

In regions where freezing weather is encountered, all water must be

drained from unit and piping when out of service (water shut off). Drain

valve must be left open until unit is returned to service.

REPLACEMENT PARTS

Replacement parts may be ordered through A. O. Smith dealers, authorized

servicers or distributors. Refer to the Yellow Pages for where to call or

contact the A. O. Smith Water Products Company, 5621 West 115th Street,

Alsip, Illinois 60803, 1-800-433-2545. In Canada contact A.O. Smith

Enterprises Ltd., P.O. Box, 310-768 Erie Street, Stratford, Ontario N5A 6T3,

1-800-265-8520. When ordering parts, be sure to state the quantity, part

number and description of the item including the complete model and serial

number as it appears on the product. Refer to the parts list for more

information.

PREVENTIVE MAINTENANCE

RECOMMENDED PROCEDURE FOR PERIODIC REMOVAL

OF LIME DEPOSITS FROM TANK TYPE COMMERCIAL

WATER HEATERS

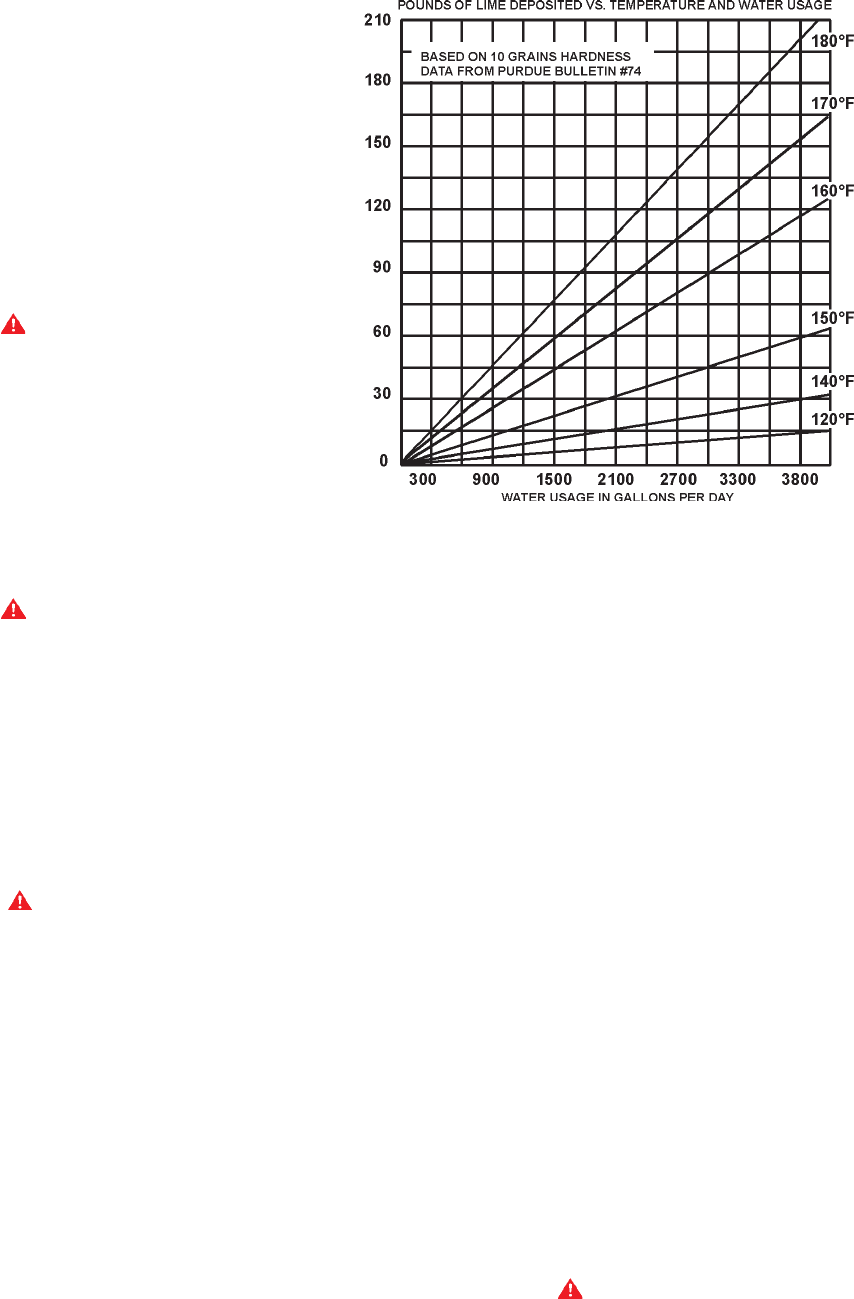

FIGURE 8

The amount of calcium carbonate (lime) released from water is in direct

proportion to water temperature and usage, see chart. The higher the

water temperature or water usage, the more lime deposits are dropped out

of the water. This is the lime scale which forms in pipes, heaters and on

cooking utensils.

Lime accumulation not only reduces the life of the equipment but also

reduces efficiency of the heater and increases fuel consumption.

The usage of water softening equipment greatly reduces the hardness of

the water. However, this equipment does not always remove all of the

hardness (lime). For this reason it is recommended that a regular schedule

for deliming be maintained.

The time between cleaning will vary from weeks to months depending upon

water conditions and usage.

Refer to A. O. Smith booklet, Form No. 4800, entitled “Why? When and

How” for detailed description on tank inspection and cleanout.

UN•LIME

®

and the booklet may be obtained through your A. O. Smith dealer

or distributor.

DELIMING SOLVENTS

A. O. Smith recommends the use of UN•LIME for deliming. UN•LIME is a

patented food grade acid which is safe to handle and does not create the

harmful fumes which are associated with other products.

UN•LIME may be obtained from your dealer, distributor or the A. O. Smith

Product Service Division. Order part no. 4763 (1 gal), packed 4 gallons

per case or part no. 4813 (5 gallon container).

Hydrochloric base acids are not recommended for use on glass-lined tanks.

CAUTION

Observe handling instructions on label of product being used.