14

TANK CLEANOUT PROCEDURE

The following practices will ensure longer life and enable the unit to operate

at its designed efficiency:

1. Once a month the heater should be flushed. Open the drain valve and

allow two gallons of water to drain from the heater. Inlet water valve

should remain open to maintain pressure in tank.

2. A cleanout opening is provided for periodic cleaning of the tank. Gas

must be shut off and heater drained before opening cleanout.

To clean heater through cleanout opening, proceed as follows:

1. Drain heater.

2. Remove outer cover plate from lower side of heater jacket.

3. Remove six (6) hex head screws securing tank cleanout plate and

remove plate.

4. Remove lime, scale, or sediment using care not to damage the glass

lining.

5. Inspect cleanout plate gasket, if new gasket is required, replace with

A. O. Smith part no. 99038.

6. Install cleanout plate. Be sure to draw plate up tight by tightening

screws securely.

7. Replace outer jacket cover plate.

In some water areas the sediment might not be removed by this method

and may result in the water heater making rumbling or boiling noises. To

dissolve and remove these more stubborn mineral deposits, A. O. Smith

UN•LIME Professional Delimer should be used.

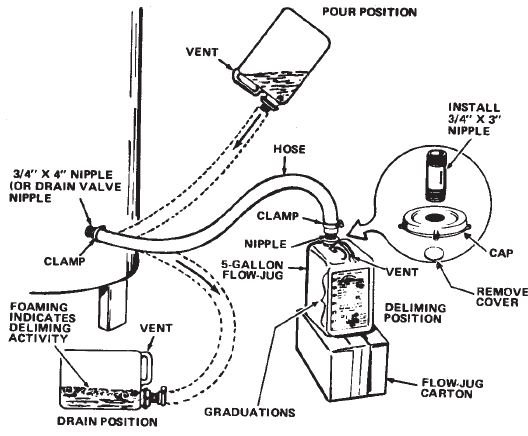

FIGURE 9

FLO-JUG METHOD OF DELIMING

The Flo-Jug is the standard 5 gallon container for UN•LIME -or- it is available

as a deliming kit with hose and fittings. Contact your dealer, distributor or

the A. O. Smith Water Products Company.

Figure 9 illustrates most of the following steps.

1. The heater should be prepared for deliming as described in the “Why?

When and How” booklet. The relief valve may also be delimed at this

time.

2. With the Flo-Jug upright:

• Take off cap, remove cover under opening and install 3/4" x 4" pipe

nipple.

• Drill or punch a 3/16" vent hole in handle. A stainless steel screw

is included with the Flo-Jug kit. This screw is to be installed in the

vent hole when Flo-Jug is not in use.

• Remove drain valve from heater and insert a 3/4" x 4" nipple.

• Connect and clamp 1" I.D. x 3" hose to Flo-Jug and heater nipple.

3. Lift the Flo-Jug to the POUR POSITION and permit the UN•LIME to

flow into the heater as rapidly as possible.

• Be sure to keep the vent just above the liquid level.

4. Place the Flo-Jug in the DELIME POSITION.

• It may be necessary to place the empty jug on its carton to trap the

solution in the heater.

• Allow the UN•LIME to attack the water scale for 5 minutes.

5. Lower the Flo-Jug to the DRAIN POSITION and allow the UN•LIME to

flow out of the heater as rapidly as possible.

• Observe the vent holes and elevate the jug slightly if there is a

possibility of spillage.

• Deliming activity is indicated by foaming on the surface of the

solution.

6. Continue the deliming process:

• Raise jug to POUR POSITION. Allow solution to flow into heater.

• Place jug in DELIME POSITION for 5 minutes. Solution is at work

in heater.

• Lower jug to DRAIN POSITION and allow solution to flow out.

Observe foaming.

7. After one hour, or earlier if the deliming activity (foaming) stops, inspect

the tank interior.

• Drain the UN•LIME back into jug, DRAIN POSITION, and then stand

jug in DELIME POSITION.

• Remove clamp, hose and pipe nipple from heater drain opening.

• Observe interior through opening - a small flashlight may be used

effectively.

• If the interior still shows water scale, the deliming process should

be continued.

• To check UN•LIME for continued use or reuse, place some lime

scale or white chalk into a glass with a small amount of solution. If

the material is vigorously dissolved by the solution, the UN•LIME

can be reused. If not, the UN•LIME has been weakened and should

be replaced.