10

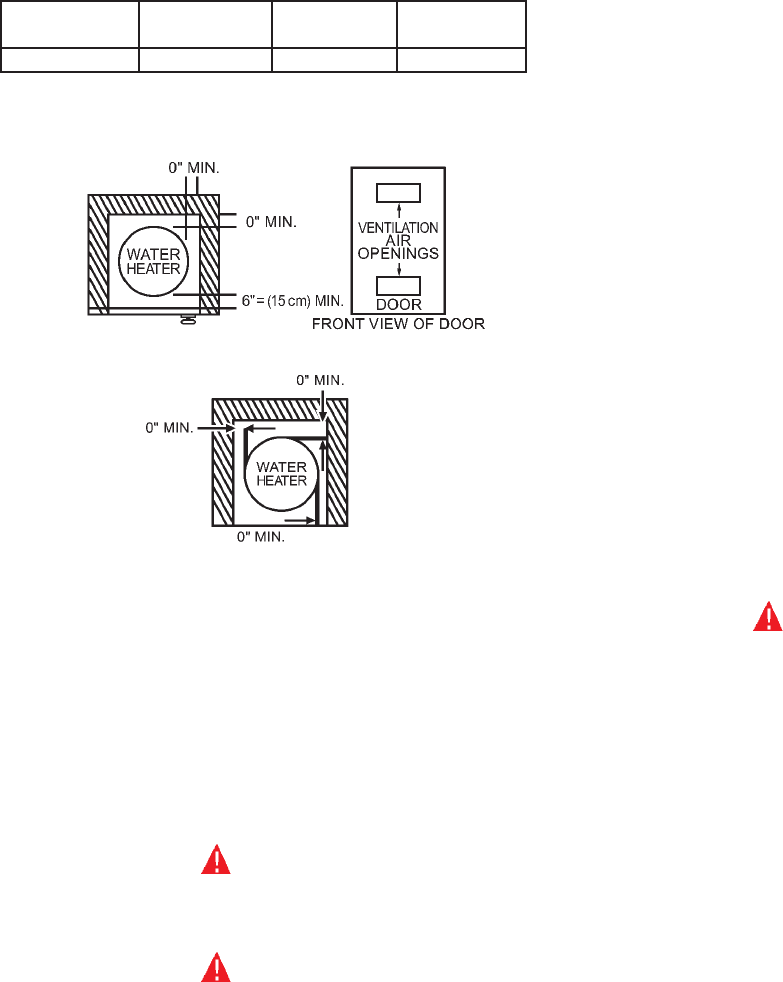

CLEARANCES

The unit is approved for installation on combustible flooring in an alcove

when the minimum clearance to combustibles is maintained per Figure 6

and the table below.

ABCD

(RIGHT SIDE) (LEFT SIDE) (BACK) (CEILING)

0" (0cm) 0" (0cm) 0" (0cm) 12" (30.5 cm)

A service clearance of 24" (61 cm) should be maintained from serviceable

parts, such as relief valves, flue baffles, flue damper devices, thermostats,

cleanout openings or drain valves.

FIGURE 5

FIGURE 6

ALCOVE INSTALLATION (ACCEPTABLE)

An alcove suitable for the installation of a water heater is a restricted

section of a room not separated from the room by a door or partition and

which meets the minimum clearances for the water heater.

*When the ceiling height exceeds 8 feet (2.4 m), you are only allowed to

consider 8 feet (2.4 m) when calculating the total volume of the enclosure.

AIR REQUIREMENTS

REFER TO THE CURRENT EDITION OF THE NATIONAL FUEL GAS CODE

ANSI Z223.1/NFPA 54.

WARNING

KEEP APPLIANCE AREA CLEAR AND FREE OF COMBUSTIBLE MATERIALS,

GASOLINE AND OTHER FLAMMABLES, VAPORS AND LIQUIDS.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION OR VENTILATING AIR.

WARNING

FOR SAFE OPERATION PROVIDE ADEQUATE AIR FOR COMBUSTION AND

VENTILATION. AN INSUFFICIENT SUPPLY OF AIR WILL CAUSE

RECIRCULATION OF COMBUSTION PRODUCTS RESULTING IN AIR

CONTAMINATION THAT MAY BE HAZARDOUS TO LIFE. SUCH A CONDITION

OFTEN WILL RESULT IN A YELLOW, LUMINOUS BURNER FLAME, CAUSING

CARBONING OR SOOTING OF THE COMBUSTION CHAMBER, BURNERS

AND FLUE TUBES AND CREATES A RISK OF ASPHYXIATION.

Where an exhaust fan is supplied in the same room with a heater, sufficient

openings for air must be provided in the walls. UNDERSIZED OPENINGS WILL

CAUSE AIR TO BE DRAWN INTO THE ROOM THROUGH THE CHIMNEY, CAUSING

POOR COMBUSTION. SOOTING MAY RESULT IN SERIOUS DAMAGE TO THE

HEATER AND RISK OF FIRE OR EXPLOSION.

UNCONFINED SPACE

In buildings of conventional frame, brick, or stone construction, unconfined spaces

may provide adequate air for combustion, ventilation and draft hood dilution.

If the unconfined space is within a building of tight construction (buildings using

the following construction: weather stripping, heavy insulation, caulking, vapor

barrier, etc.), air for combustion, ventilation and draft hood dilution must be obtained

from outdoors. The installation instructions for confined spaces in tightly constructed

buildings must be followed to ensure adequate air supply.

CONFINED SPACE

When drawing combustion and dilution air from inside a conventionally

constructed building to a confined space, such a space shall be provided

with two permanent openings, ONE IN OR WITHIN 12 INCHES (30.5 cm)

OF THE ENCLOSURE TOP AND ONE IN OR WITHIN 12 INCHES (30.5 cm)

OF THE ENCLOSURE BOTTOM. Each opening shall have a free area of at

least one square inch per 1000 Btuh (2,225mm²/Kw) of the total input of

all appliances in the enclosure, but not less than 100 square inches (645

square cm).

If the confined space is within a building of tight construction, air for

combustion, ventilation, and draft hood dilution must be obtained from

outdoors. When directly communicating with the outdoors or communicating

with the outdoors through vertical ducts, two permanent openings, located

in the above manner, shall be provided. Each opening shall have a free

area of not less than one square inch per 4000 Btuh (8,900mm²/Kw) of the

total input of all appliances in the enclosure. If horizontal ducts are used,

each opening shall have a free area of not less than one square inch per

2000 Btuh (4,450mm²/Kw) of the total input of all appliances in the enclosure.

MECHANICAL EXHAUSTING OF ROOM AIR

Where an exhaust fan is installed in the same room with a heater, sufficient

openings for air must be provided in the walls. UNDERSIZED OPENINGS

WILL CAUSE AIR TO BE DRAWN INTO THE ROOM THROUGH THE HEATER'S

VENTING SYSTEM, CAUSING POOR COMBUSTION AND/OR SOOTING

WHICH MAY RESULT IN SERIOUS DAMAGE TO THE HEATER AND RISK OF

FIRE OR EXPLOSION. IT CAN ALSO CREATE A RISK OF ASPHYXIATION.

COMBUSTION AIR AND EXHAUST

WARNING

WHEN DETERMINING THE INSTALLATION LOCATION FOR A POWER

DIRECT VENT WATER HEATER, SNOW ACCUMULATION AND DRIFTING

SHOULD BE CONSIDERED IN AREAS WHERE APPLICABLE.

VENTING CLEARANCES

VENTING THROUGH AN OUTSIDE WALL-CLEARANCES

• 1" (2.5 cm) clearance for 4" or 6" PVC or CPVC piping from combustible

surfaces for outlet piping.

• 0" clearance for 4" or 6" PVC or CPVC piping from combustible surfaces

for inlet piping.

• 18" (46 cm) minimum in all directions from any obstruction, such as a wall,

that may interfere.

• 18" (46 cm) minimum from the ground and 9" from ceiling overhangs.

See Figure 7.

• The Power Direct Vent outlet terminal shall terminate a least 36" (91 cm)

above any forced air inlet located within 10 feet. See Figure 8.

• The Power Direct Vent outlet terminal shall terminate at least 36" (91 cm)

below, 36" (91 cm) horizontally from or 18" (46 cm) above any door,

window or gravity air inlet into the building. See Figure 8.

• 18" (46 cm) minimum from other natural draft (gravity) direct vent, power

vent or power direct vent appliance inlet and/or outlet vent(s) when directly

above or 135° to either side of center line. See Figure 9.

• 36" (91 cm) minimum from any appliance inlet and / or outlet vents when

directly below or 45° to either side of center line. See Figure 9.

• Vent termination must not be within 4 feet of any items such as gas

meters, gas valves or other gas regulating equipment.

• The venting system must be installed in a manner which allows inspection

of the installation of the venting pipes and joints as well as periodic

inspection after installation as required by ANSI Standards.