Installation and Service Manual Upsilon-Series

33

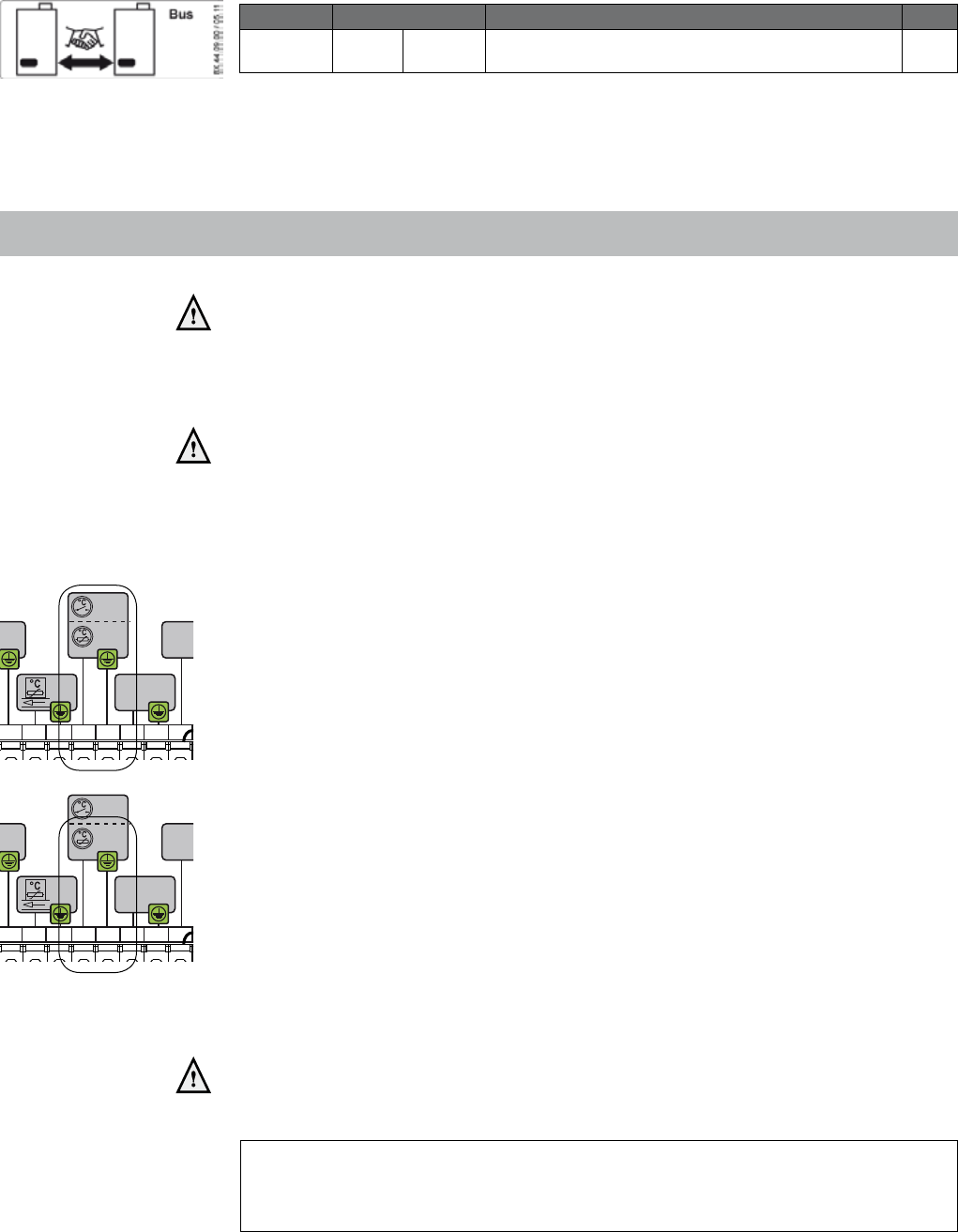

gure 8.f

4. Bus communication: 4-pole connector

Position Connection Application PG

Bus communication cable IP67

The 0310289 bus communication cable mutually connects the cascaded boilers by

4-pole connectors on the side of the connection terminals (2 boilers: 1 cable, 3 boilers:

2 cables etc.) and is tted with 2 IP67 tulles. A maximum of 8 boilers can be connected

to the system.

8.1 Externalcontrols

NOTE: -T10mustbeconnected

-T4isadvicedtoconnect.

The Upsilon boiler provides in many possibilities to operate the boilers from external

controls.

Only1typeofcontrolcanbeconnected.Connectionsoftheexternalcontrolmust

bedoneinthemasterboiler(address01)onterminal3andappropriateconnec-

tions.

Below you will nd a description of the possibilities and parameter adjustments to take

account of.

1. On-Offcontact

An On-Off contact is a volt-free switch to create a heat demand with closed contact.

The On-Off control must be connected to terminal 3, position 7 and 8. This is also the

connection for an OpenTherm-control, but it is self-detecting. No specic adjustments

are necessary. See chapter 9.4 to adjust the ow temperature.

2. OpenTherm-control

An OpenTherm-control is a digital controller which is communicating with the boiler ac-

cording the OpenTherm-protocol. The controller calculates continuously the desired ow

water temperature and sends this to the boiler(s).

The OpenTherm-control must be connected to terminal 3, position 7 and 8. This is also

the connection for an On-Off contact, but it is self-detecting.

After connecting an OpenTherm-control P230 will be visible (Setting level, Param. Chap-

ter, Cascade Param.) where the maximum setpoint CH can be adjusted.

For control option 1 and 2 counts that the boiler controls its own output (modulating) to

achieve the desired temperature. When this is achieved the boiler modulates back to

maintain the desired temperature and prevents over shoot.

If an OpenTherm controller is used, it must be ensured that for certain error

messagestheheatdemandisnotomitted.Thiscanresultincompletelossof

heatproduction.

0-10Volt

Open-

Therm

On/Off

T3

DHW

1 2 3 4 5 6 7 8 9 10 11 12 13 14

T10

General

purpose

LWCO

T4

Out

Figure 8.1.a

0-10Volt

Open-

Therm

On/Off

T3

DHW

1 2 3 4 5 6 7 8 9 10 11 12 13 14

T10

General

purpose

LWCO

T4

Out

Figure 8.1.b

OpenThermerrormessages

ThecodingofthetransmittedErrorMessagesonaOpenThermcontrollerisdisplayedasfollows:

(E)EB(E=ErrorCode=Bandboilernumber)

example:ErrorCodeEx02SC02onboiler6willappearas(0)26