Installation and Service Manual Upsilon-Series

15

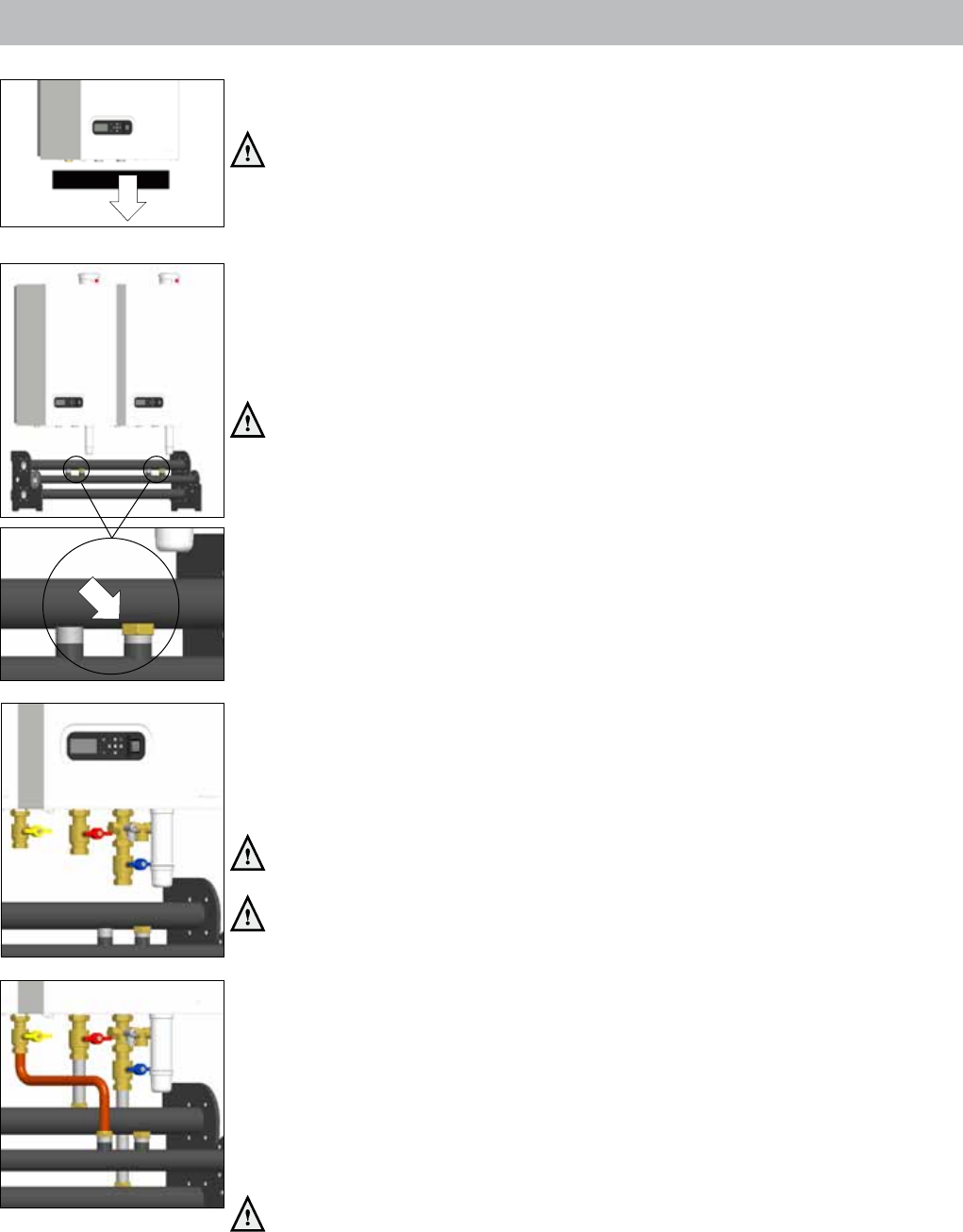

5.4 Connectingtheboiler

A. Remove the remaining packaging part from the bottom of the boiler.

Note:thispackagingpartisprovidedwithboilerpartswhichareneededfor

mountingtheboiler.

B. Cap the connections that are not used on the pipe work headers:

Flow and return: ø35mm blind compression tting (2 items/boiler)

Gas: 1 ¼" blind cap with gasket (1 item/boiler)

Forconnections,usethesuppliedgaskets.Checkallconnectionsforleakage

andgas-tightness.

C. Connect the isolations valves to the boiler:

Flow: 1½" at coupling x 35mm compression isolation valve with red handle

Return: 1½" at coupling x 35mm compression tting cross union with

ll/drain valve and isolation valve

Fit according to the installation design choice the supplied 3 or 4 bar overow safety

valve in the cross union.

Gas: 1¼" x 28mm gas isolation valve

Pollutedtestwatermaybereleasedwhenremovingtheplasticcapsonthe

boilerowandreturn.

Forconnections,usethesuppliedgaskets.Checkallconnectionsforleakage

andgas-tightness.

D. Connect the valves to the pipe work headers:

Flow: 35mm pipe pieces with 35mm compression ttings (elbow and socket)

Return: 35mm pipe pieces with 35mm compression ttings (elbow and socket)

Gas: 28mm pipe piece with 1¼" at and 28mm compression tting

Back-to-back installation:

Flow: 35mm pipe pieces with 35mm compression ttings (bend and socket)

Return: 35mm pipe pieces with 35mm compression ttings (bend and socket)

Gas: 28mm pipe piece with 1¼" at and 28mm compression tting

Forconnections,usethesuppliedgaskets.Checkallconnectionsforleakage

andgas-tightness.

E. Fill the siphon with tap water and t the siphon cup underneath the boiler.

The siphon cup is supplied separately and can be found behind the housing.

Figure 5.4.b

Figure 5.4.c

Figure 5.4.d

Figure 5.4.a