31

S

TART

-

UP

P

ROCEDURE

AND

A

DJUSTMENT

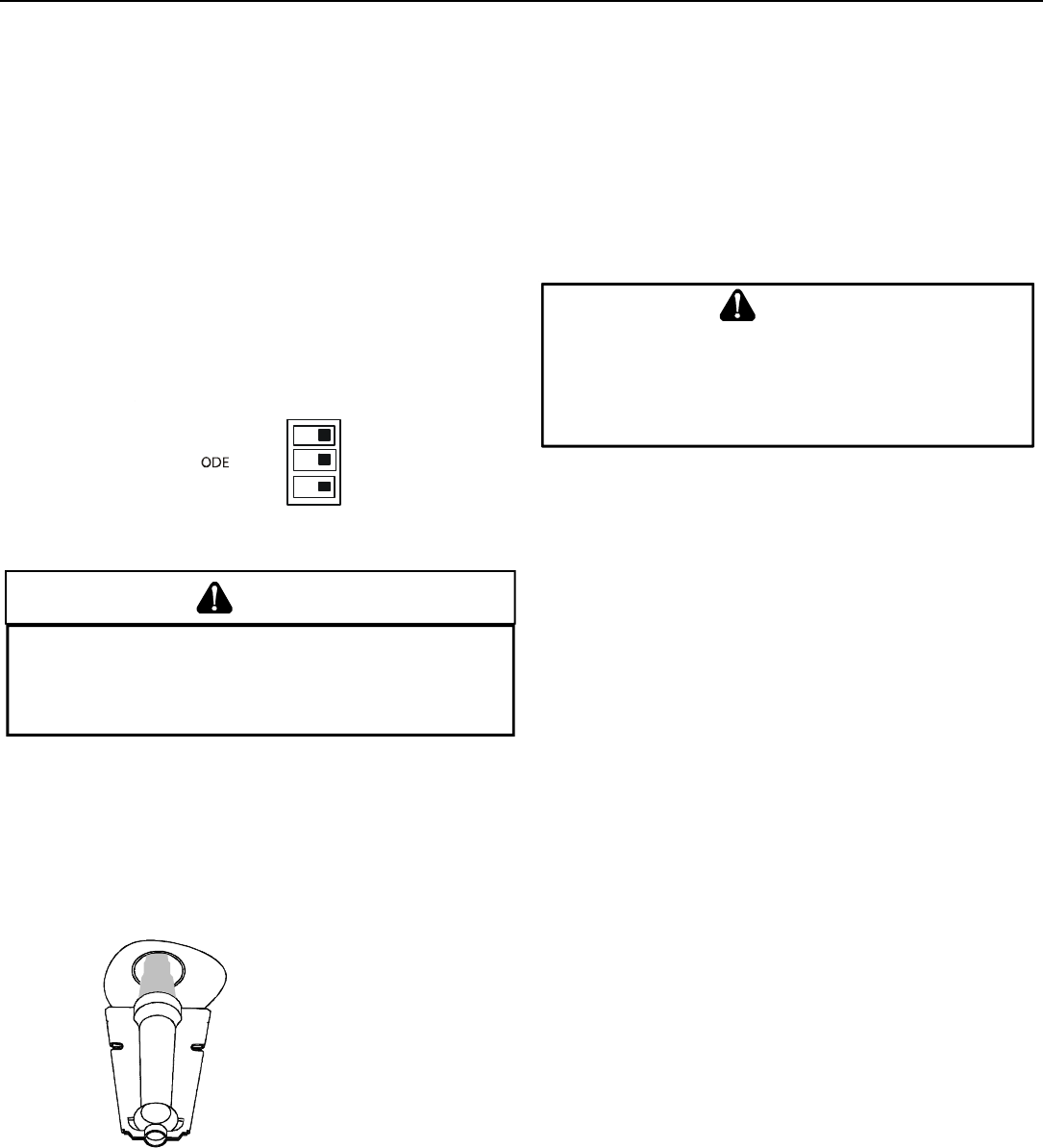

Setting the Mode switch to “2 STG” allows the furnace to

operate at the furnace’s highest input AND at an input rate

that is 75% of the highest input rate. For this mode of

operation, the furnace operates at the low input rate for a

pre-determined time period then steps to the high input rate.

Operation is as described under Sequence of Operation

(Integrated Ignition Control) – Mode DIP Switch is set to “2

STG” position.

The time period is determined by the 2

nd

Stg Dly DIP switch.

Setting the 2

nd

Stg Dly DIP switch to 5 minutes fixes the

delay period at 5 minutes. Setting the 2

nd

Stg Dly DIP

switch to Auto enables an algorithm that calculates a delay

period based on the heating cycle time and the total cycle

time. The delay period can range from 1 minute to 12

minutes.

5 MIN

OFF

ON

1 STG

AUTO

2 STG

M

2

ND

STG DLY

O

PERATIONAL

C

HECKS

WARNING

T

O AVOID PERSONAL INJURY OR DEATH, DO NOT REMOVE ANY INTERNAL

COMPARTMENT COVERS OR ATTEMPT ANY ADJUSTMENT.

E

LECTRICAL

COMPONENTS ARE CONTAINED IN BOTH COMPARTMENTS.

C

ONTACT A

QUALIFIED SERVICE AGENT AT ONCE IF AN ABNORMAL FLAME APPEARANCE

SHOULD DEVELOP.

BURNER F LAME

The burner flames should be inspected with the burner com-

partment door installed. Flames should be stable, quiet, soft,

and blue (dust may cause orange tips but they must not be

yellow). Flames should extend directly outward from the burn-

ers without curling, floating, or lifting off. Flames must not

impinge on the sides of the heat exchanger firing tubes.

Check the burner flames for:

1. Good adjustment

2. Stable, soft and blue

3. Not curling, floating, or lifting off.

Burner Flame

AUXILIARY L IMIT CONTROL

Auto reset limits are located on or near the blower. To access

this auxiliary limit, disconnect the electrical power and remove

the blower door. The auxiliary limit control is designed to pre-

vent furnace operation in case of main blower failure on hori-

zontal installations. It may also open if the power supply is

interrupted while the furnace is firing. The auxiliary limit control

is suitable for both horizontal right and horizontal left installa-

tions. Regardless of airflow direction, it does not need to be

relocated.

T

O

AVOID

PERSONAL

INJURY

OR

DEATH

,

DO

NOT

REMOVE

ANY

INTERNAL

COMPARTMENT

COVERS

OR

ATTEMPT

ANY

ADJUSTMENT

.

E

LECTRICAL

COMPONENTS

ARE

CONTAINED

IN

BOTH

COMPARTMENTS

.

C

ONTACT

A

QUALIFIED

SERVICE

AGENT

AT

ONCE

IF

AN

ABNORMAL

FLAME

APPEARANCE

SHOULD

DEVELOP

.

WARNING

S

AFETY

C

IRCUIT

D

ESCRIPTION

GENERAL

A number of safety circuits are employed to ensure safe and

proper furnace operation. These circuits serve to control any

potential safety hazards and serve as inputs in the monitoring

and diagnosis of abnormal function. These circuits are con-

tinuously monitored during furnace operation by the integrated

control module.

INTEGRATED C ONTROL M ODULE

The integrated control module is an electronic device which

controls all furnace operations. Responding to the thermostat,

the module initiates and controls normal furnace operation, and

monitors and addresses all safety circuits. If a potential safety

concern is detected, the module will take the necessary pre-

cautions and provide diagnostic information through an LED.

PRIMARY LIMIT

The primary limit control is located on the partition panel and

monitors heat exchanger compartment temperatures. It is an

automatic reset, temperature sensor. The limit guards against

the overheating resulting from insufficient air passing over the

heat exchanger.

AUXILIARY L IMIT

The auxiliary limit control is located either on or near the circu-

lator blower and monitors heat exchanger compartment tem-

peratures. The control is an automatic reset, temperature

sensor. It guards against overheating resulting from insufficient

air passing over the heat exchanger.