18

Resolute

®

Acclaim Woodburning Stove

2000893

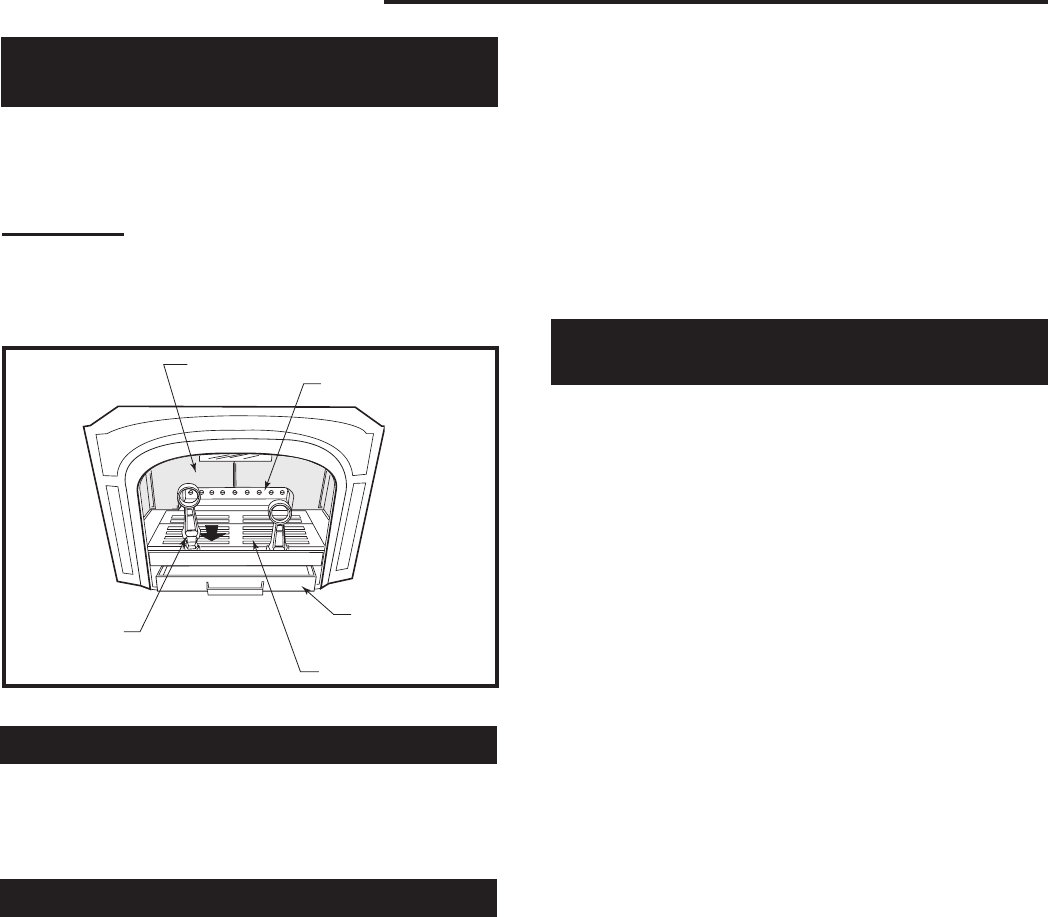

The slip into pockets cast into the front of

the bottom grate and can be removed when loading

through the front door. (Most Acclaim owners, however,

prefer the convenience of “smokeless” top loading.)

The andirons must be in place during

operation. (Fig. 28) They not only help keep the

clear for fireviewing, but they assure proper

placement of the fuel load for efficient clean-burning

operation.

ST612

Resolute Acclaim

firebox

1/01

Firebricks

Secondary Air

Ports

Ash Pan

Bottom Crates

Removable

Andirons

ST612

A look inside the firebox of the Resolute Acclaim.

Burning wood is said to be more of an art than a sci-

ence. You’ll easily master the art if you start by using

good, dry fuel, and understand how the stove’s air sup-

ply system operates.

This heater is designed to burn natural wood only; do

not burn fuels other than those for which this heater

was designed.

Higher efficiencies and lower emissions generally result

when burning air-dried, seasoned woods as compared

to softwoods or freshly cut hardwoods. Avoid burning

“green” wood that has not been properly seasoned.

Also, do not use construction materials or trash as fuel;

the chemicals, coatings and hardware that may be

present can cause damage to the refractory material.

•

The best hardwood fuels include oak, maple, beech,

ash, and hickory that has been split, stacked, and air-

dried outside under cover for at least one year. Avoid

burning cordwood that is over 2 years old as such fuel

can contribute to short burn times, backpuffing and

over-firing.

•

For areas that do not have a supply of hardwood, some

of the better softwoods that are commonly burned

include tamarack, yellow pine, white pine, Eastern red

cedar, fir, and redwood. They too should be properly

dried. The length of the wood should be 16” (406 mm).

Use of wood shorter than 16” may result in decreased

burn times.

Wood should be stored under cover to maintain dry-

ness. Even for short-term storage, keep wood a safe

distance from the heater and keep it out of the areas

around the heater used for refueling and ash removal.

No single control setting will fit every situation. Each

operation will differ depending on the quality of the fuel,

the amount of heat desired, and how long you wish the

fire to burn.

Control settings also depend on your particular instal-

lation’s “draft,” or the force that moves air through the

stove and up through the chimney. Draft is affected

by such things as the length, type, and location of the

chimney, local geography, nearby obstructions, and

other factors.

Too much draft may cause excessive temperatures in

the stove. On the other hand, too little draft can cause

backpuffing into the room and/or insufficient heat.

How do you know if your draft is excessively high or

low? Symptoms of too much draft include an uncontrol-

lable burn or a part of the stove or chimney connector

glowing red. Inadequate draft is indicated by smoke

leaking into the room through the stove or chimney con-

nector joints.

In some newer homes that are well-insulated and

weather-tight, poor draft may result from insufficient air

in the house. In such cases it may be necessary to duct

combustion air to the stove directly from outside. In fact,

in some areas, outside combustion air is required for

stove installations in all new construction.

Your Resolute Acclaim is designed to easily incorporate

outside combustion air with a Vermont Castings Out-

side Air Duct Adapter #3255 available from your local

dealer.

When first using the stove, keep track of the air control

settings. You will quickly find that a specific setting will

give you a fixed amount of heat. It may take a week or

two to determine the amount of heat and the length of

burn you should expect from various settings.

Most installations do not require a large amount of com-

bustion air, especisally if adequate draft is available. Do

not for any reason attempt to increase the firing rate of

your heater by altering the air control adjustment range

outlined in these directions.