9

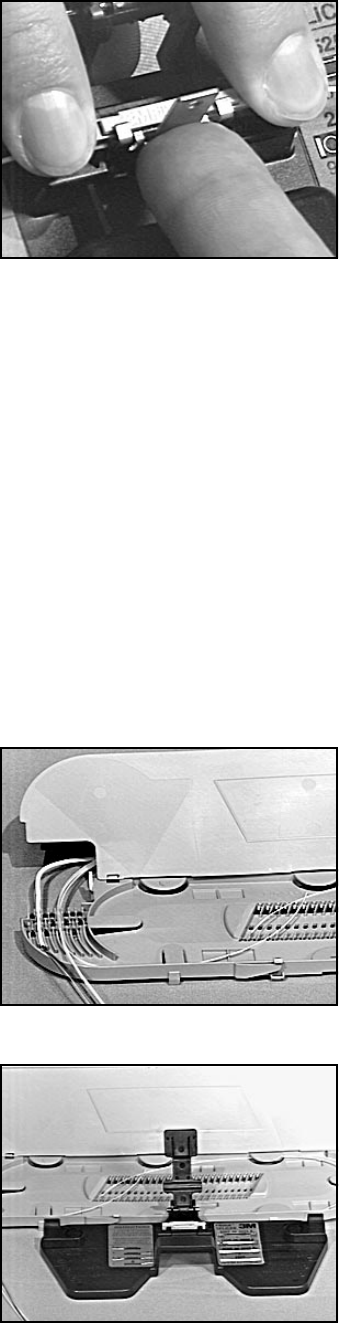

5.04 Hold the cap lifter in place with one hand and push down on

the ends of the splice with the other hand. This action should

reseat the splice into the holding cradle and lift the cap at the

same time.

5.05 Repeat fiber centering and splice actuation (See step 4.06 –

4.09.) If after two attempts an acceptable splice loss is not

obtained, remove fiber, strip, clean and re-cleave. Re-splice

using a new splice.

6.0 Fiber Organization and Splice Storage

6.01 When storing fiber slack in a splice tray, the spliced fiber ends

will twist one full turn for each full loop of fiber being stored.

This rotation places stress on the fibers. This rotational stress

makes fiber organization more difficult and may affect fiber/

splice performance, particularly in 900 m coated fibers. The

stiffness of the 900 m fiber does not distribute this stress in

the same manner as 250 m coated fiber. The following

procedure is strongly recommended when splicing 900 m

coated fibers and will improve fiber organization when

splicing all fiber types.

6.02 Secure the buffer tubes of the fibers to be spliced to the tray

so that the fibers are free to rotate through the point of

attachment.

6.03 Select the first two fibers to be spliced and lay them into the

tray. Trim the fibers so they are the right length for splicing

plus approximately 1 to 2 inches (2.5 to 5 cm) for fiber end

preparation.

6.04 Place the splice assembly tool close to or on top of the splice

tray. Match the orientation of the tool to that of the splice

holder or tray whenever possible.