5

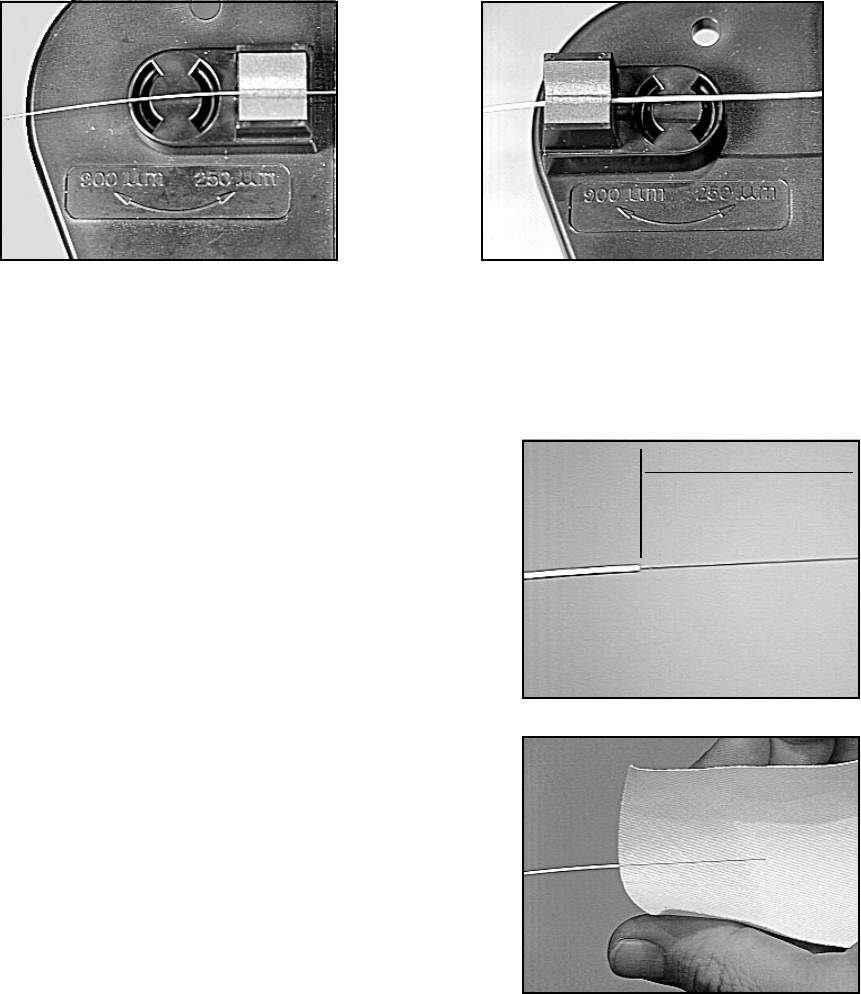

2.05 If using the Fibrlok 2501 Assembly Tool, rotate the toggle

arms for the appropriate fiber size.

Inward – 250 m Outward – 900 m

3.0 Fiber Preparation

3.01 Remove the minimum length of fiber required to prepare and

splice the fibers.

3.02 Strip approximately 1 to 2 inches (25 mm to 51 mm) of

plastic coating from the fiber using a mechanical stripper.

Note: The stripper should be in good operating condition to

prevent scratches or other damage to the glass cladding.

3.03 Clean the bare glass by pulling the fiber through an alcohol

soaked lint-free wipe. This will remove any fragments or dirt

remaining on the fiber.

Note: Do not wipe the fibers more than two times, and limit the

time that the bare fiber is exposed to the atmosphere.

Note: Carefully follow health, safety and environmental

information on container label or Material Data Sheet for

isopropyl alcohol being used.

3.04 Cleave fiber to 12.5 mm ≠0.5 mm (0.492 ≠0.020 inches).

Important: The Fibrlok

™

II 2529 Universal Splice uses a cleave length of

12.5 mm

≠0.5 mm (0.492 ≠0.020 inches) for both 250 m and

900

m coated fibers.

Note: The cleaver should be in good operating condition and used

in accordance with the manufacturer's instructions. It is

recommended that the cleaver provide a consistent cleave-

to-coating length within

≠0.5 mm. In addition, standard

cleavers should produce cleaved ends within 2

≠ of

perpendicular and free of major defects. Cleavers

specifically designed to produce controlled, angled cleaves

of greater than 2

≠ may also be used with the Fibrlok

™

II

Optical Splice.

1" to 2" (25 mm - 51 mm)

(depending on cleaver)