4

1.04 Tools and Materials Required are as follows:

• Fibrlok

™

2500 or 2501 Assembly Tool

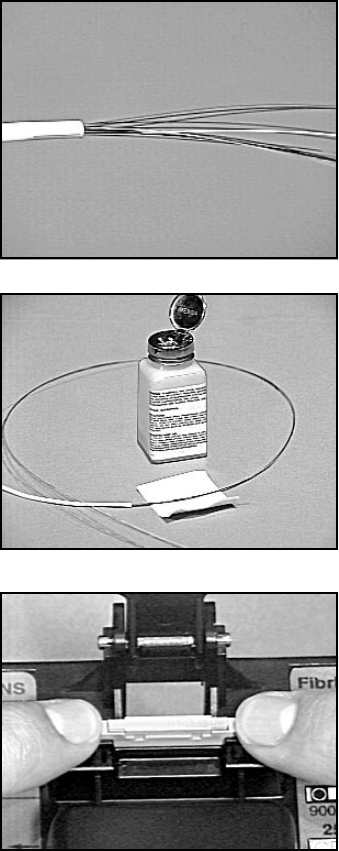

• Plastic Coating (Buffer) Stripper

• Reagent Grade Isopropyl Alcohol

• Lint-free Wipes

• Cleaver

• Fibrlok 2505 Assembly Tool

Mounting Adaptor (optional)

• Fibrlok

™

II Video Instruction Tape (optional)

• Tool Kit (optional)

1.05 Some Compatible Organizers are:

• 3M 2118, 3M 2524, 3M 2672

• AT&T UC-SS/M1

• GTE Part 910470 0000, 910470 1000

• Siecor M67-070

• Keptel LightLink

Others compatible with minor modifications:

• DiTel UST 3000, UST 3010, UST 3500

• AT&T 846 280 626, 846 280 634,

846 280 642, 846 280 659

• Raychem FOSC 100/TK

2.0 Splicing Set-Up

2.01 The splicing area should be clean, dry and well-lighted.

A clean, well-organized splicing area will improve splice

efficiency and minimize the risk of contamination of fibers or

splices.

2.02 Open the buffer tubes, expose and clean the fibers per your

company practice.

Note: Storage, use and disposal of isopropyl alcohol should be

per your company health, safety and environmental

instructions. Refer to solvent label or Material Safety

Data Sheet.

2.03 See Section 6.0 for recommended procedures for fiber

organization and splice storage.

2.04 Remove Fibrlok splice from protective package. Load the

splice into the assembly tool by pressing firmly at the ends of

the splice.

Note: Carefully follow health, safety and environmental

information on Fibrlok II Splice label or Material Safety

Data Sheet.