7

IMPORTANT SAFEGUARD

IMPORTANT SAFEGUARD

IMPORTANT SAFEGUARD

IMPORTANT SAFEGUARD

5. Tape Width:

Minimum – 36 mm [1-1/2 inches]

Maximum – 48 mm [2 inches]

1. Power Requirements:

Electrical – 115 VAC, 60 Hz, 3.8 A

These machines are equipped with an 2.4 m

[8 foot] standard neoprene covered power cord

and a grounded plug.

Contact your 3M Representative for power

requirements not listed above.

8. Box Board:

Style – regular slotted containers – RSC

Bursting test –125 to 275 P.S.I. single wall or

double wall B or C flute.

7. Tape Leg Length (Standard):

70 mm ± 6 mm [2-3/4 inches ±1/4 inch]

Tape Leg Length (Optional):

48 mm ± 6 mm [2 inches ±1/4 inch]

(To change tape leg length to 48 mm [2 inches],

see "Special Set-Up Procedures", page 25.)

Specifications

(Specifications continued on next page)

3. Operating Conditions:

Use in dry, relatively clean environments at

5

o

to 40

o

C [40

o

to 105

o

F] with clean, dry boxes.

Important – Machine should not be washed

down or subjected to conditions causing

moisture condensation on components.

4. Tape:

Scotch

TM

brand pressure-sensitive film box

sealing tapes.

6. Tape Roll Diameter:

Up to 405 mm [16 inches] maximum on a

76.2 mm [3 inches] diameter core.

(Accommodates all system roll lengths of

Scotch

TM

brand film tapes.)

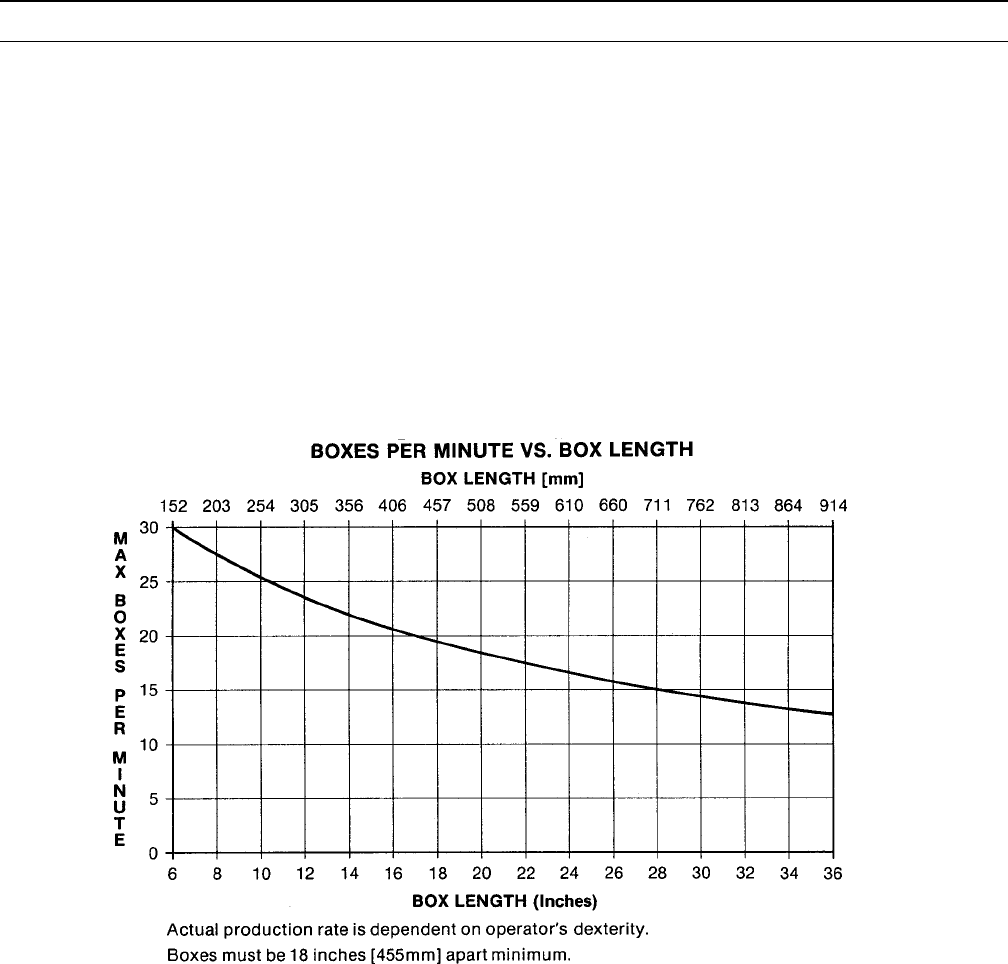

2. Operating Rate:

Belt speed is 0.40 m/s [78 ft/min]