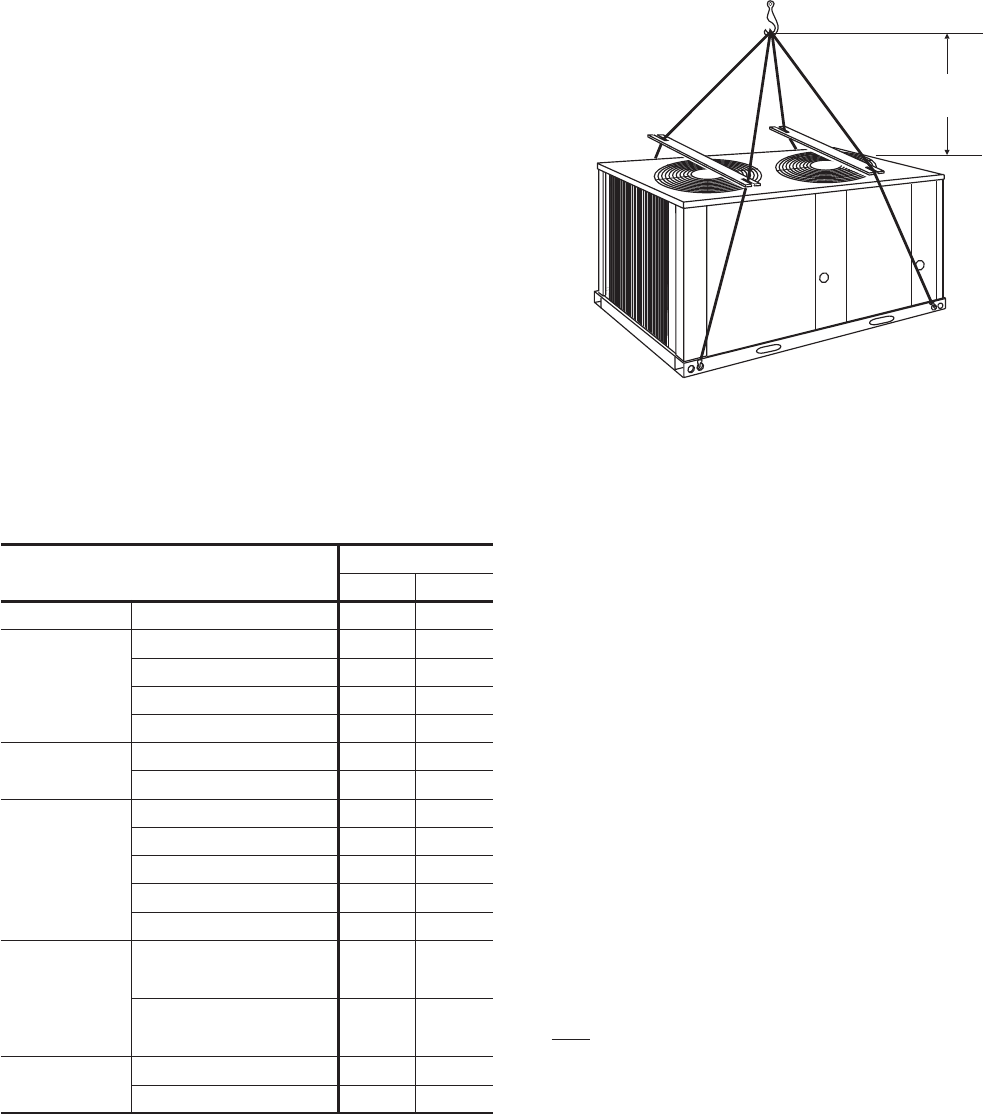

CAUTION: LENGTH OF FORKS MUST BE A MINIMUM OF

54" (when lifting from the compressor end of the

unit) anda MINIMUMOF 42"(when liftingfrom the

front or rear of the unit).

Remove the nesting brackets from the four corners on top of

the unit. All screws that are removed to take these brackets off

must be replaced on the unit.

CLEARANCES

All units require certain minimum clearances for proper opera

-

tion and service. Refer to Figure 4 for these clearances.

WARNING: Do not permit overhanging structures or shrubs

to obstruct air discharge.

Additional height may be required for snow clearance if winter

operation is expected.

COMPRESSOR CRANKCASE HEATER

The compressor is equipped with a crankcase heater to pre

-

vent refrigerant from mixing with crankcase oil during the

“OFF” cycle. The heaters will be energized when the com

-

pressor is not running providing the unit disconnect switch is

closed.

CAUTION: Do not attempt to start the compressor without at

least eight hoursof crankcase heat or compressor

damage will occur.

Ifa unithasjust beeninstalledorthe unitdisconnectswitchhas

beenopen fora longperiod oftime, movethe systemswitch on

the room thermostat to the “OFF” position before closing the

unit disconnect switch. Eight hours of crankcase heat are re

-

quired to drive the liquid refrigerant out of the compressor bef

-

ore the compressor can be started.

POWER AND CONTROL WIRING

Install electrical wiring in accordance with the latest National

Electrical Code (NFPA Standard No. 70) and/or local regula-

tions. The unit should be grounded in accordance with these

codes.

POWER WIRING

Check the voltage of the power supply against the data on

the unit nameplate. Check the size of the power wire, the

disconnect switch and the fuses against the data in Table 3.

NOTE: Copper conductors mustbe installed between the dis

-

connect switch and the unit.

Refer to Figure 4 for the location of the power wire access

opening through the front of the unit. This opening will re

-

quire a field-supplied conduit fitting.

The field-supplied disconnect switch must be suitable for an

outdoor location. Although it should be installed near the unit,

do NOT

secure it to the unit cabinet.

Refer to Figure 3 for typical field wiring.

CONTROL WIRING

Refer to Figure 4 for the location of the control wire access

opening through the front of the unit.

Route the necessary low voltage control wires from terminal

block TB2 of the unit control box through this access open

-

ing to the indoor unit and to the room thermostat. Refer to

Figure 3 for typical field wiring.

The room thermostat should be mounted about 5 feet above

the floor and located where it will be exposed to normal room

air circulation. Do not locate it on an outside wall, near a

supply air grille, or where it may be affected by sunlight

4 Unitary Products Group

035-16192-001-A-1001

O

O

O

O

O

O

O

O

O

O

FIG. 2 - TYPICAL RIGGING

5 ft.

MIN

DESCRIPTION

UNIT MODEL

EFB180 EFB240

Compressor

1

Rating - (Qty) Tons (2) 7-1/2 (2) 10

Fans

Quantity 2 2

Diameter - inches 24 26

Blades/Pitch (°) 3/32 3/36

Nominal CFM 10862 11395

Fan Motors

2

HP 1 1

RPM 1100 1100

Rows Deep X Rows High 2 X 40 2 X 40

Finned Length - inches 130 130

Face Area - square feet 36.11 36.11

Tube(Copper) OD - inches 3/8 3/8

Fins (Aluminum) per inch 18 20

Holding Charge

(Sys 1 / Sys 2)

3

1-0/1-0 1-0/1-0

Operating Charge

(Sys 1 / Sys 2)

4

16-8/17-8 19-0/19-0

Shipping 970 1020

Operating 980 1040

1

These compressors are fully hermetic.

2

The ball bearing, 48 frame, single phase condenser fan motor have internal

protection and are directly connected to the condenser fins. Motor rotation is

counterclockwise when viewing the lead end, which is opposite the shaft end.

3

The amount of charge in the unit as shipped from the factory.

4

Totaloperatingchargeforthecondensingunit,matchingindoorunit,and25feet

of interconnecting pipe.

TABLE 2 - PHYSICAL DATA