28

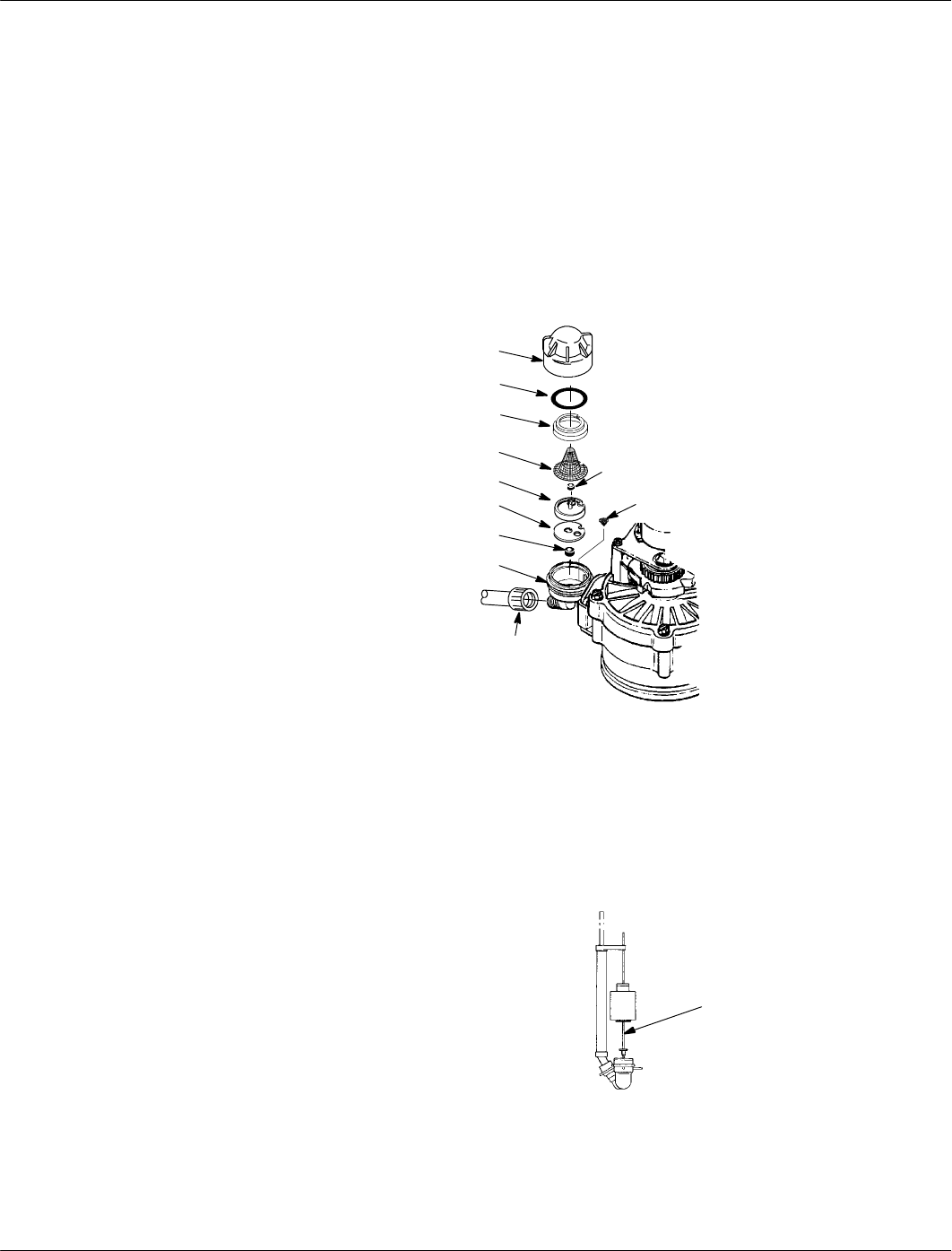

Cleaning the Nozzle and Venturi

A clean nozzle and venturi (see Figure 13) is a must for the conditioner to work properly. This small

water softener creates the suction to move brine from the brine tank, into the resin tank. If it should

become plugged with sand, silt, dirt, etc., the conditioner will not work, and you will get hard water.

To get to the nozzle and venturi, remove the top cover. Be sure the water softener is in soft water cycle

(no water pressure at nozzle and venturi). Then, holding the nozzle and venturi housing with one hand,

turn off the cap. Do not lose the o--ring seal. Lift out the screen support and scree n. Then, remove the

nozzle and venturi. Wash the parts in warm, soapy water and rinse in fresh water. If needed, use a small

brush to remove iron or dirt. Do not scratch, misshape, etc., surfaces of the nozzle and venturi. Also,

check and clean the gasket and flow plug(s).

Replace all parts in the correct order. Lubricate the o--ring seal with silicone grease and locate in

position. Install and tighten the cap, by hand only. Do not overtighten and break the cap or housing.

*Install with lettered side up

concavesidedown.

Cap

O --- r ing sea l

Screen support

Screen

Nozzle & venturi

Gasket

*Flow plug (HVDC)

Nozzle & venturi housing

Screen

IMPORTANT: Be sure

small hole in the gasket is

centered directly over the

small hole in the nozzle &

venturi housing.

*Flow plug

Ferrule nut

Figure 13

Recharge the softener several times to reduce water level in the tank. This will also assure that the

softener is completely recharged and ready to provide softened water again. Once the water level in

the tank is about 2” to 3”, you may resume normal use. If the water level does not drop after a couple

of recharges, do the following:

Remove the brine valve assembly from the brinewell and pushfloat stem down. Place opening of brine

valve just under the water and start a recharge. Move the brine valve down with each recharge, until

it rests at the bottom of the tank. Add salt, if needed, and return to normal use.

Brine valve assembly is

inside the brinewell, located

in the salt storage tank.

Float stem

(push down)

Figure 14

If you have questions about routine maintenance...

call 1--866--986--3223, Monday -- Friday, 8 am to 9 pm, EST.