Part number 550-110-282/1108

40

GOLD

CGs-4E Gas-Fired Water Boiler — Boiler Manual

Service & maint. — annual start-up (continued)10b

❏ Check/test . . .

Gas piping

1. Sniffnearoorandaroundboilerareaforanyin-

dication of a gas leak.

2.

Test gas piping using bubble test,perSection5

of this manual, if there is any indication of a leak.

Cold fill and operating pressures

1. While the system is cold, note the pressure reading

ontheboilerpressure/temperaturegauge.Verifythat

cold fill pressure is correct.

2.

Watch the pressure as the boiler and system heat

up to ensure pressure rise is normal. Too high a rise

would indicate a waterlogged or undersized expan-

sion tank.

Air vents and air elimination

1. Inspectautomaticairvents(ifused).Alsoinspect

air separators to ensure they are operational.

2. The cap must be unscrewed one turn to allow air to

escape.

3. See

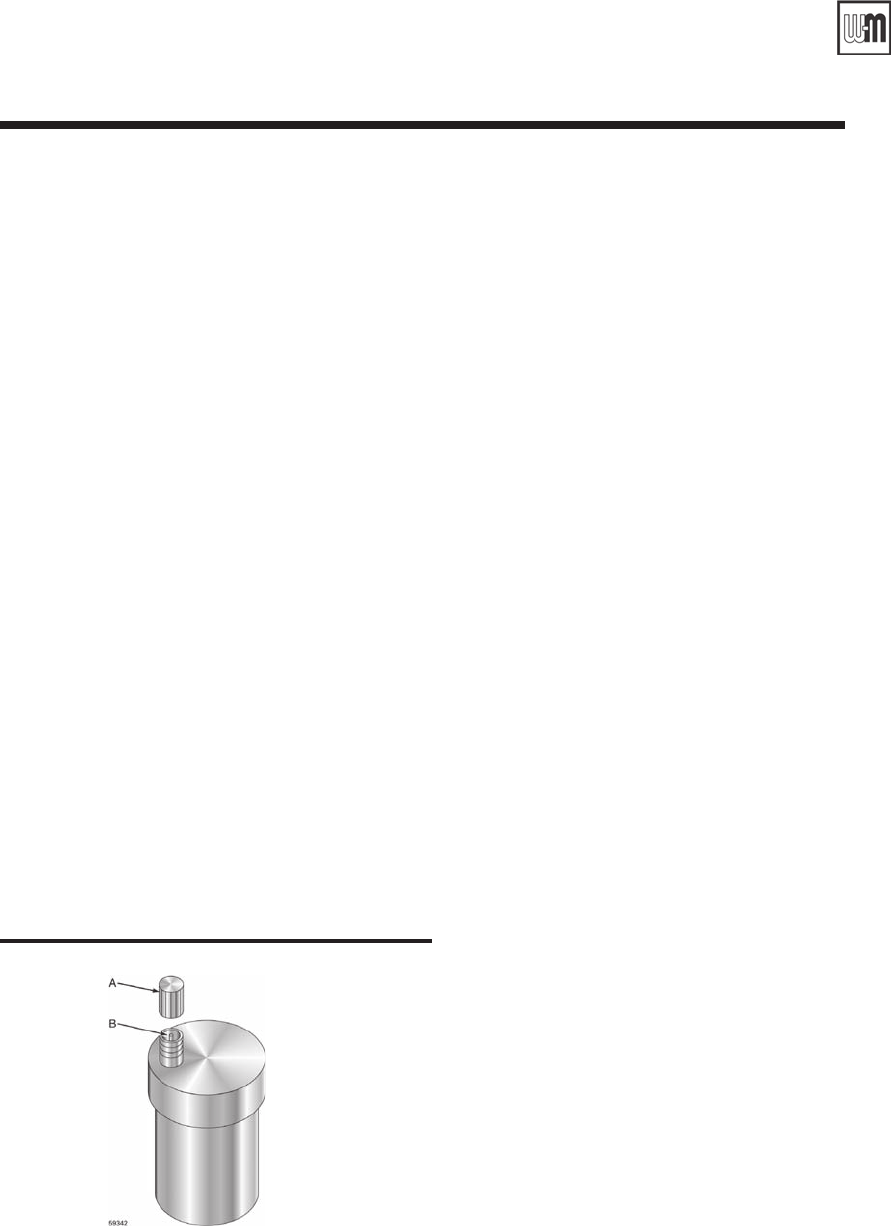

Figure 22. If the air vent is leaking, remove cap

A and briefly push valve B and then release to clean

the valve seat.

4. Replace cap

A by twisting all the way onto valve B

and then unscrewing one turn.

Figure 22 Automatic air vent, typical

Limit controls and cutoffs

1. Inspectandtesttheboilerlimitcontrol.Verifyop-

eration by turning control set point below boiler

temperature.Boilershouldcycleoff.Returndialto

original setting.

2. Inspect and test additional limit controls or low

water cutoffs installed on system.

Expansion tank

1. Expansiontanksprovidespaceforwatertomovein

an out as the heating system water expands due to

temperature increase or contracts as the water cools.

Tanks may be open, closed or diaphragm or bladder

type.SeeSection3 of this manual for suggested best

location of expansion tanks and air eliminators.

Open-type — located above highest radiator or

baseboard unit, usually in the attic or closet. Has a

gauge glass and overflow pipe to a drain.

Closed-type — welded gas tight and located above

boiler. Tank is partially filled with water, leaving an

air cushion for expansion.

• Makesurethistypeoftankisttedwitha

tank

tting

,suchastheB>ank-Trol or Taco

Taco-Trol. This fitting reduces gravity circula-

tion of air-saturated tank water back to the

system and prevents the air from bubbling up

through the water as it returns from the sys-

tem.

•

Do not use automatic air vents in systems

with closed-type tanks.

The air will escape

from the system instead of returning to the tank.

Eventually,thetankwillwaterlogandnolonger

control pressurization. The boiler relief valve

will weep frequently.

Diaphragm- or bladder-type — welded gas tight

with a rubber membrane to separate the tank pres-

surizingairandthewater.Maybelocatedatany

point in the system, but most often found near the

boiler.

• Systemswiththistypeofexpansiontankrequire

at least one

automatic air vent, preferably lo-

cated on top of an air eliminator, as shown in

examplesinmanualSection3.

2. If relief valve has tended to weep frequently, the ex-

pansion tank may be waterlogged or undersized.

Closed-type tank — tank is most likely water-

logged. Install a tank fitting if not already installed.

Then check fill level per fitting manufacturer’s

instructions. If fill level is correct, check tank size

against manufacturer’s instructions. Replace with

a larger tank if necessary.

Diaphragm- or bladder-type — first, check tank

size to be sure it is large enough for the system. If

size is too small, add additional tank(s) as neces-

sary to provide sufficient expansion. If tank size is

large enough, remove tank from system and check

charge pressure (usually 12 psig for residential ap-

plications). If tank won’t hold pressure, membrane

has been damaged. Replace tank.