82 WSHP-SVX01D-EN

Preventive Maintenance

Maintenance on the unit is simplified

with the following preventive sugges-

tions:

Filter maintenance must be performed

to assure proper operation of the

equipment. Filters should be inspect-

ed at least every three months, and re-

placed when it is evident they are

dirty. Filter sizing includes:

WARNING

Hazardous

Voltage!

Disconnect all electric power, in-

cluding remote disconnects be-

fore servicing. Follow proper

lockout/tagout procedures to en-

sure the power can not be inad-

vertently energized. Failure to

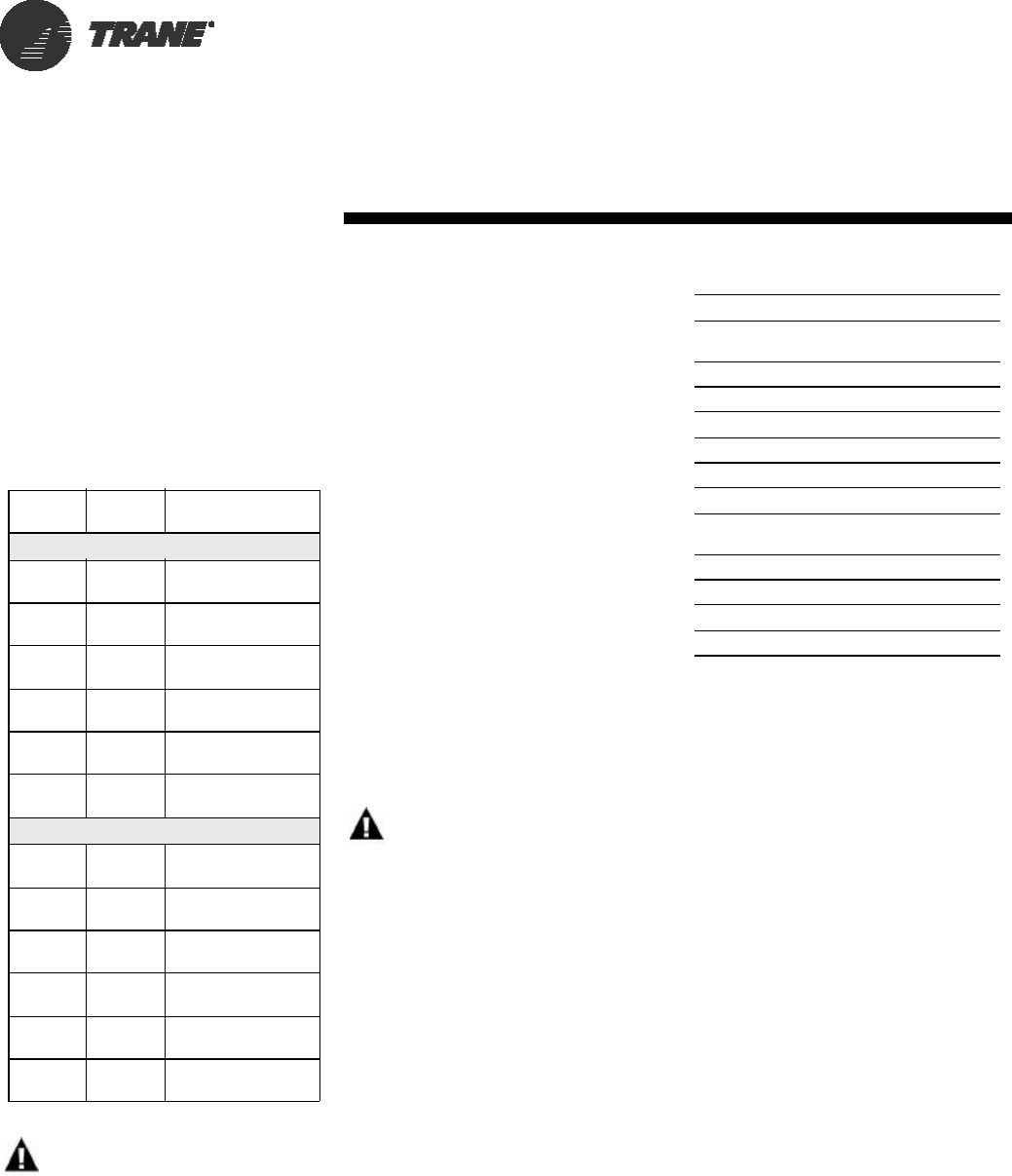

Size

60 HZ

Size

50 HZ

Filter Size

GEH

006-015 006-012

14 5/8" x 20 1/4"

(371 x 514)

018-030 015-024

16 3/8" x 23 5/8"

(416 x 600)

036-042 030-036

18 5/8" x 25 3/8"

(473 x 645)

048-060 042-060

20 5/8" x 29 3/4"

(524 x 755)

072-120 072-090

20 x 20 (3)

(508 x 508)

150-180 120-150

25 x 25 (3)

(635 x 635)

GEV

006-015 006-012

15 7/8" x 19 7/8"

(403 x 504)

018-030,

040

015-024

17 7/8" x 24 7/8"

(454 x 632)

036-042 030-036

19 7/8" x 24 7/8"

(504 x 632)

048-060 042-060

27 7/8" x 29 7/8"

(708 x 759)

GEV 072-

120

090

20 x 20 (4)

(508 x 508)

150-300 120-240

19 5/8" x 24 5/8" (6)

(498 x 625)‘

disconnect power before servic-

ing could result in death or seri-

ous injury.

Check the contactors and relays within

the control panel at least once a year.

It is good practice to check the tight-

ness of the various wiring connections

within the control panel.

A strainer (60 mesh or greater) must

be used on an open loop system to

keep debris from entering the unit heat

exchanger and to ensure a clean sys-

tem.

For units on well water, it is important

to check the cleanliness of the water-

to-refrigerant heat exchanger. Should

it become contaminated with dirt and

scaling as a result of bad water, the

heat exchanger will have to be back

flushed and cleaned with a chemical

that will remove the scale. This service

should be performed by an experi-

enced service person.

WARNING

Hazardous

Chemicals!

Coil cleaning agents can be either

acidic or highly alkaline. Handle

chemical carefully. Proper han-

dling should include goggles or

face shield, chemical resistant

gloves, boots, apron or suit as re-

quired. For personal safety, refer

to the cleaning agent manufactur-

ers Materials Safety Data Sheet

and follow all recommended safe

handling practices. Failure to fol-

low all safety instructions could

result in death or serious injury.

It should be noted that the water qual-

ity should be checked periodically. See

Table 11.

Maintenance

Condensate Trap

For units incorporating a negative trap

design, ensure that the condensate

system is primed with water at all

times. Allowing a negative, pressure

condensate system to run dry could

cause a break in the condensate seal

allowing the fan to draw water from

the condensate line to spray moisture

into the mechanical system. By

maintaining a primed condensate trap,

a seal will be created and will help

prevent these complications.

Table 11: Water Quality Table

Scaling

Calcium and magnesium

(total hardness)

Less than 350 ppm

Corrosion

pH 7-9.5

Hydrogen Sulfide Less than 1 ppm

Sulfates Less than 25 ppm

Chlorides Less than 125 ppm

Carbon Dioxide Less than 75 ppm

Total dissolved solids

(TDS)

Less than 1000 ppm

Biological Growth

Iron Bacteria Low

Erosion

Suspended Solids

Low