WSHP-SVX01D-EN 51

Sound Attenuation Pad

For sound sensitive installations, a vi-

bration pad (field provided) should be

placed beneath the horizontal or verti-

cal equipment. For the horizontal unit,

the pad should be approximately

twice the size of the unit foot print. For

the vertical unit, the pad should be 1/2"

(12.7 mm) thick, and equal to the over-

all unit foot print.

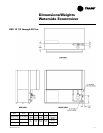

Hanging the Horizontal Unit

To hang the horizontal configuration:

(1) Install the hanging isolators (locat-

ed in the return-air section of the unit)

into the four hanging brackets.

(2) Secure the equipment to a joist,

concrete, etc. with the use of 3/8"

(9.7 mm) field provided (all-thread)

rod. Each corner should contain field

provided nuts and washers to com-

plete the hanging installation.

(3) Unit slope or pitch should conform

to national and local codes. This is the

responsibility of the contractor.

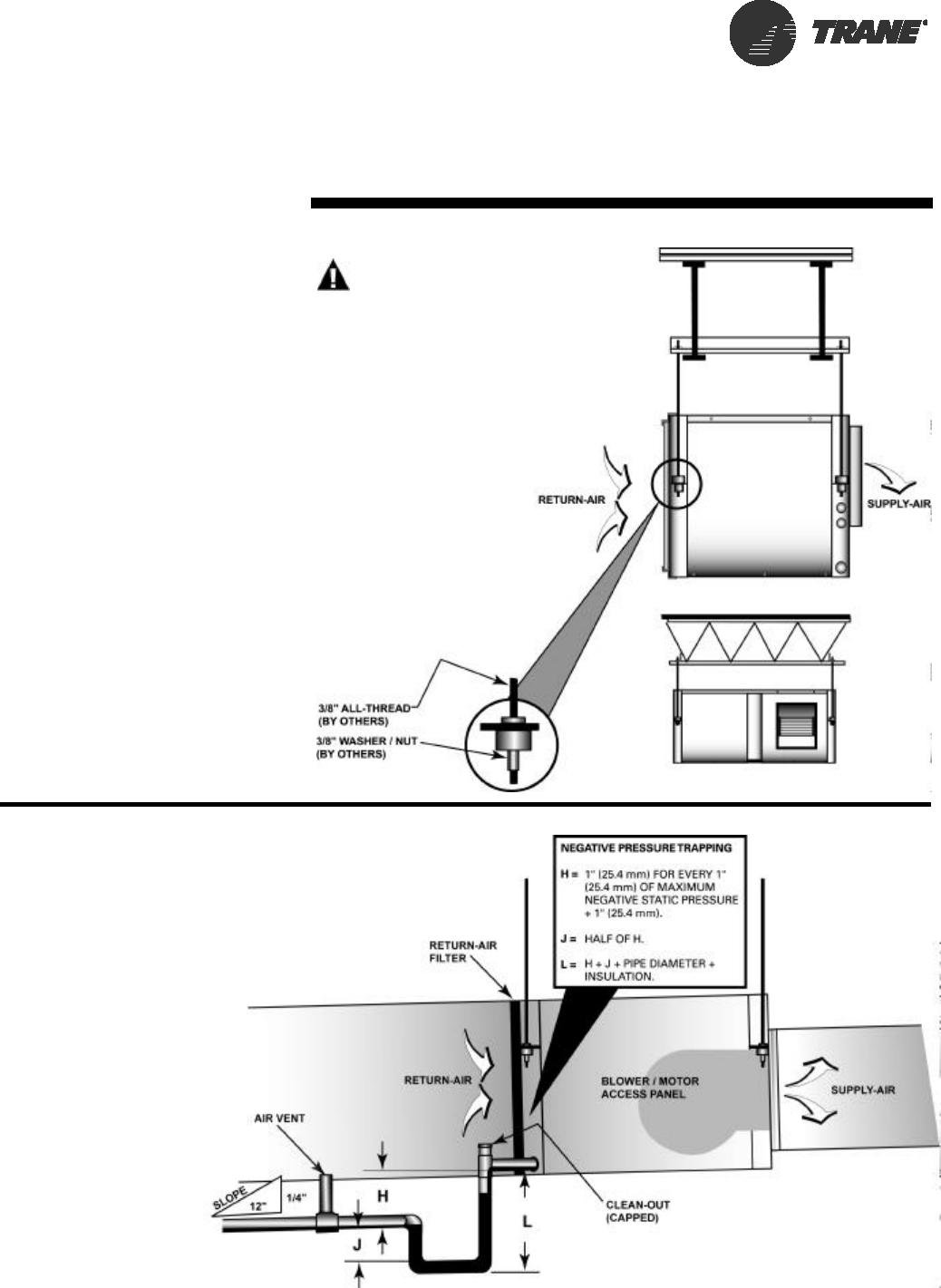

Condensate Drain Connection

Install proper trapping to the equip-

ment. The unit drain connection is 3/4"

(19 mm) for all GEH and GEV models.

When designing the condensate trap

for the water-source system, it’s im-

portant to consider the unit’s draw-

thru design requiring negative pres-

sure trapping.

In a properly trapped system,

when condensate forms during

normal operation, the water level

in the trap rises until there is a

constant flow. It is imperative to

maintain water in the trap and

not allow the trap to dry out dur-

ing heating season. Keeping

trap primed at all times will

enable the water to flow

properly. See Figure 6 for

appropriate dimensions

required in a negative pressure

system.

Installation

WARNING

Improper Unit Lift!

Test lift unit approximately 24

inches to verify proper center of

gravity lift point. To avoid drop-

ping of unit, reposition lifting

point if unit is not level. Failure to

properly lift unit could result in

death or serious injury or

possible equipment or prop-

erty-only damage.

Figure 6: Negative pressure system