WSHP-SVX01D-EN 53

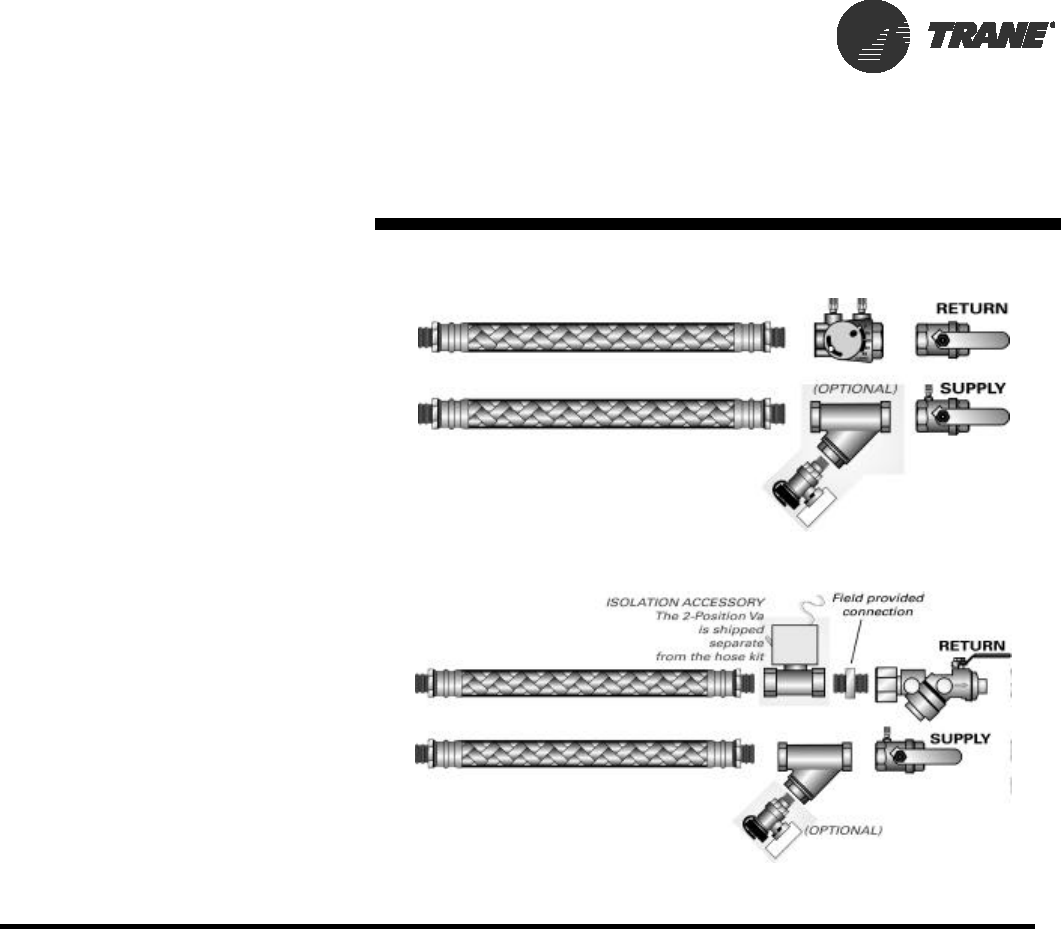

Types of Hose Connections

(3) A circuit setter provides a means of

manually balancing the water flow to

the heat pump. This manual in-line

balancing method is accurate up to

±20%. In order to determine flow rate,

the user must record both handle posi-

tion, and differential pressure drop.

Then, the user must consult a chart

containing both pieces of information

and make the necessary adjustments

to the circuit setter.

(4) For self balancing flow control, a

Hays Measurflo® balancing hose kit

provides a constant flow rate over the

pressure differential range of 2 to 80

psid. As system pressures change

(through the addition of heat pumps,

for example) each individual flow con-

trol valve will automatically adjust to

the new system conditions.

Additional accessories, such as a

strainer are recommended for use to

eliminate contaminants from entering

the co-axial water-to-refrigerant heat

exchanger.

Cleaning and Flushing

the Water Loop

After the piping system is complete,

the flexible hose connectors should be

doubled back to complete the water

circuit external to the unit (avoiding

trash settle-out in the condenser). An

extra pipe may be necessary to con-

nect the hose kits.

(1) Water circulation system should be

filled with clean water using the water

make up connections. Note: Air vents

should be open during filling.

(2) With the air vents closed, start the

circulating pump and then crack the air

vents to bleed off the trapped air, as-

suring circulation through all compo-

nents of the system.

Installation

Option 3: Flexible hoses with ball valves and circuit setter

Option 4: Flexible hoses with automatic balancing flow control

Note: Make up water must be available

to the system to replace the volume

formerly occupied by the air that is

bled off.

(3) With the air vented and the water

circulating, the entire system should

be checked for leaks with repairs made

as required.

(4) Operate the supplementary heat

system (boiler) making checks per

manufacturer’s instructions. During

this operation, visual checks should be

made for leaks that may have occurred

due to increased heat. Repair as re-

quired.

(5) Open the system at the lowest point

for the initial blow down (making sure

the make up water is equal to the water

being dumped). Continue blow down

until the water leaving the drain runs

clear, but not less than 2 hours.

(6) Shut down pumps and supplemen-

tary heat system. Reconnect the hoses

placing the water-to-refrigerant heat

exchanger in the water circulating sys-

tem.

Note: Vents should be open when the

pumps and supplementary heat sys-

tem are shut down.