CG-PRC007-EN12

point and adequate ethylene glycol

concentration for safe operation.

The maximum catalog leaving solution

temperature from the evaporator is 65°F

for outdoor ambients up to 115°F. High

leaving water temperatures exceeding

this may result in excessive suction

temperatures and, therefore, inadequate

motor cooling. For applications requiring

high leaving water temperatures, contact

your local Trane sales office for

suggested alternatives.

The maximum water temperature that

can be circulated through an evaporator,

when the unit is not operating, is

108°F (100°F for CGA 8, 10, 12½ and 15

ton chillers). The evaporator becomes

thermal stress limited at these

temperatures.

2

Supply Water Temperature Drop

The performance data for Trane chillers is

based on a chilled water temperature

drop of 10°F. Temperature drops outside

this range will result in unit performance

that differs from that cataloged. For

performance data outside the 10°F range

see the “Performance Adjustment

Factors” section in this catalog. Chilled

water temperature drops from 6 to 18°F

(8 to 12°F in CGA units) may be used as

long as minimum and maximum water

temperature and minimum and

maximum flow rates are not violated.

Temperature drops outside 6 to 18°F (8

to 12°F in CGA units) are beyond the

optimum range for control and may

adversely affect the controller’s

capability to maintain an acceptable

supply water temperature range.

Further, temperature drops of less than

6°F may result in inadequate refrigerant

superheat. Sufficient superheat is always

a primary concern in any direct

expansion refrigeration system and is

especially important in a package chiller

where the evaporator is closely coupled

to the compressor. When temperature

drops are less than 6°F, an evaporator

runaround loop may be required.

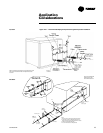

TYPICAL WATER PIPING

All building water piping must be

flushed prior to making final connections

to the chiller. To reduce heat loss and

prevent condensation, insulation should

be applied. Expansion tanks are also

usually required so that chilled water

volume changes can be accommodated.

A typical piping arrangement is shown

on the following page.

WATER VOLUME IN THE LOOP

(MINIMUM LOOP TIME)

The volume of water in the loop is critical

to the stability of system operation. The

minimum required water volume is

dependant on the chiller controller and

system GPM. Water volumes less than

the minimum required for the system

can cause nuisance problems including

low pressure trips and freezestat trips.

The cause of these trips is “Short Water

Loops”.

The minimum required water volume

(as a function of loop time and GPM) is

as follows:

CGAF: Minimum Loop Volume = GPM

x 3 Minute Loop Time

CGA: Minimum Loop Volume = GPM

X 5 Minute Loop Time

If the loop piping does not contain

enough volume, then a tank should be

added so that the equations hold true.

Generally, the more the loop volume the

greater the system stability and

controllability.

EXAMPLE: CGAFC50 with 100 gpm.

Minimum Loop Volume =

GPM x 3 Minute Loop Time

Minimum Loop Volume = 100 x 3

300 Gallon Minimum Loop Volume

If a chiller is attached to an on/off load

such as a process load, it may be difficult

for the controller to respond quickly

enough to the very rapid change in

return solution temperature. This

condition may result in freezestat or low

temperature trips. In this case, it may be

necessary to add a mixing tank in the

return line.

MULTIPLE UNIT OPERATION

Whenever two or more units are used

on one chilled water loop, Trane

recommends that their operation be

controlled from a single control device,

such as a Trane Tracer system. The

“Stand-alone” alternative is the DDC

Chiller Sequencer.

1

Series Operation

Some systems require large chilled

water temperature drops (16 to 24°F). For

those installations, two units with their

evaporators in series are usually

required. Control of the units should be

from a common temperature sensor to

prevent the separate unit controls from

fighting one another and continually

hunting. It is possible to control water

temperature from the two individual unit

controls, but a common temperature

controller provides a positive method for

preventing control overlap, more closely

matching system load and simplifying

compressor lead-lag capability.

2

Parallel Operation

Some systems require more capacity or

standby capability than a single machine

can provide. For those installations, two

units with their evaporators in a parallel

configuration are typical. The only

effective way of controlling two units in

parallel is with a single temperature

controller. For further information,

please contact Trane Applications.

Application

Considerations