30

(2) Characteristics required for flux

• Activated temperature of flux coincides with

the brazing temperature.

• Due to a wide effective temperature range, flux

is hard to carbonize.

• It is easy to remove slag after brazing.

• The corrosive action to the treated metal and

brazing filler is minimum.

• It excels in coating performance and is harm-

less to the human body.

As the flux works in a complicated manner as

described above, it is necessary to select an

adequate type of flux according to the type and

shape of treated metal, type of brazing filler and

brazing method, etc.

(3) Types of flux

• Noncorrosive flux

Generally, it is a compound of borax and boric

acid.

It is effective in case where the brazing tem-

perature is higher than 800°C.

• Activated flux

Most of fluxes generally used for silver brazing

are this type.

It features an increased oxide film removing

capability due to the addition of compounds

such as potassium fluoride, potassium chloride

and sodium fluoride to the borax-boric acid

compound.

(4) Piping materials for brazing and used braz-

ing filler/flux

Piping

material

Copper - Copper

Copper - Iron

Iron - Iron

Used brazing

filler

Phosphor copper

Silver

Silver

Used

flux

Do not use

Paste flux

Vapor flux

Do not enter flux into the refrigeration cycle.

When chlorine contained in the flux remains

within the pipe, the lubricating oil deteriorates.

Therefore, use a flux which does not contain

chlorine.

When adding water to the flux, use water

which does not contain chlorine (e.g. distilled

water or ion-exchange water).

Remove the flux after brazing.

7-5-3. Brazing

As brazing work requires sophisticated techniques,

experiences based upon a theoretical knowledge, it

must be performed by a person qualified.

In order to prevent the oxide film from occurring in

the pipe interior during brazing, it is effective to

proceed with brazing while letting dry Nitrogen gas

(N2) flow.

Never use gas other than Nitrogen gas.

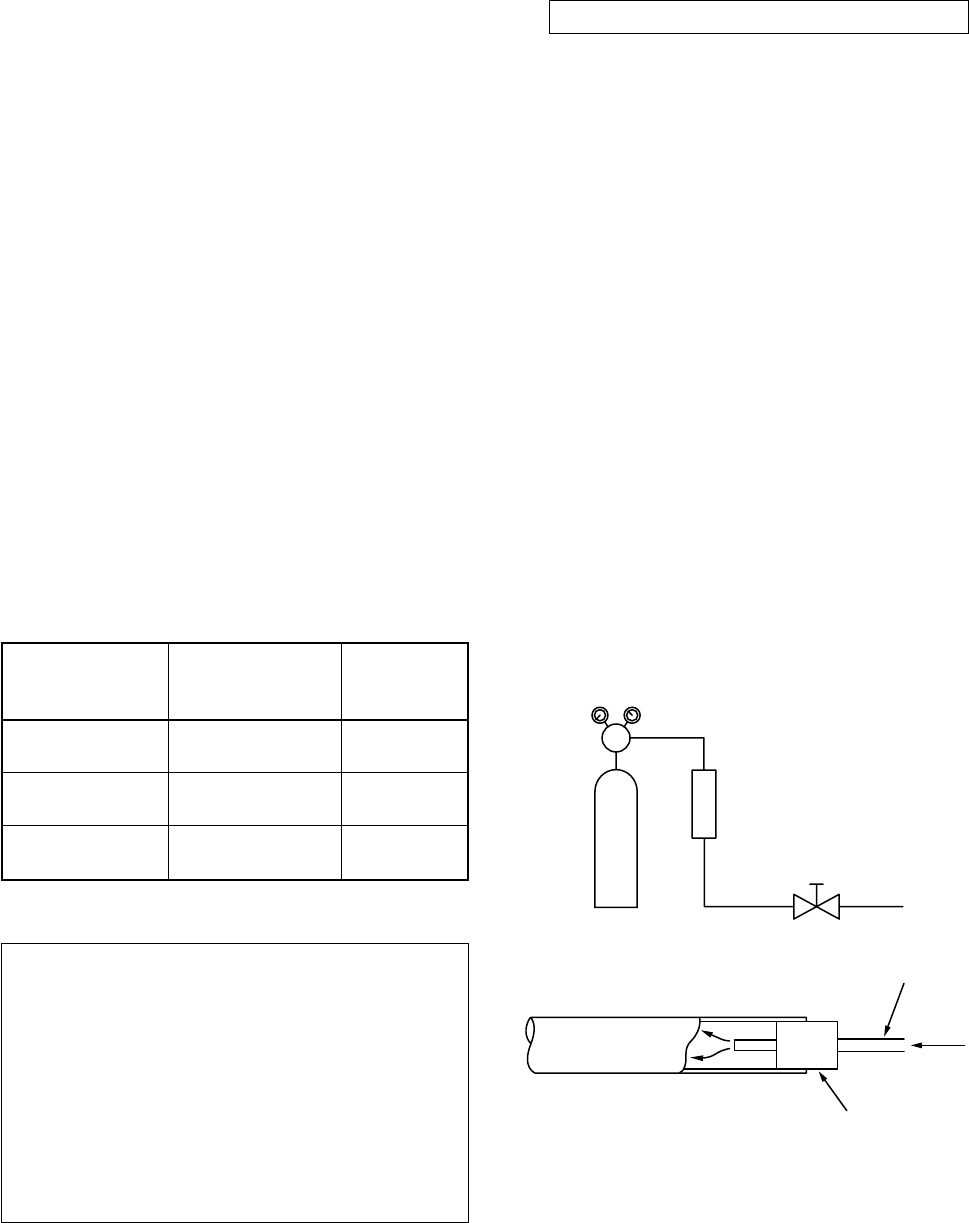

(1) Brazing method to prevent oxidation

Attach a reducing valve and a flow-meter to

the Nitrogen gas cylinder.

Use a copper pipe to direct the piping mate-

rial, and attach a flow-meter to the cylinder.

Apply a seal onto the clearance between the

piping material and inserted copper pipe for

Nitrogen in order to prevent backflow of the

Nitrogen gas.

When the Nitrogen gas is flowing, be sure to

keep the piping end open.

Adjust the flow rate of Nitrogen gas so that it

is lower than 0.05 m³/Hr or 0.02 MPa (0.2kgf/

cm²) by means of the reducing valve.

After performing the steps above, keep the

Nitrogen gas flowing until the pipe cools

down to a certain extent (temperature at

which pipes are touchable with hands).

Remove the flux completely after brazing.

Fig. 7-5-1 Prevention of oxidation during brazing

Nitrogen gas

cylinder

Pipe

Flow meter

M

Stop valve

From Nitrogen cylinder

Nitrogen

gas

Rubber plug