–17–

SMMS-i

Installation Manual

SMMS-i

Installation Manual

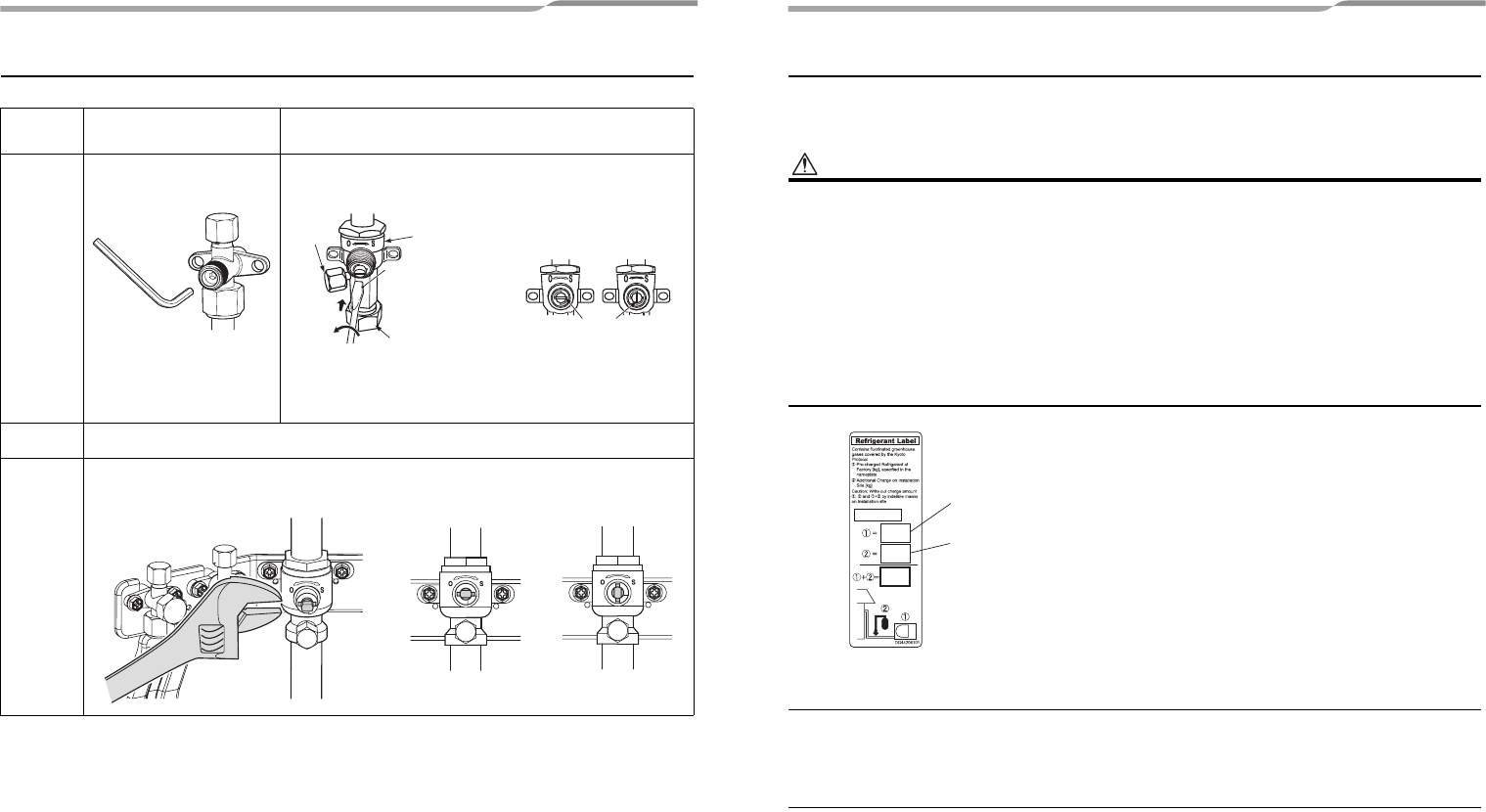

Full opening of the valve

Open the valves of the outdoor unit fully.

MAP080

MAP100

MAP120

MAP140

MAP160

Liquid side

Packed valve

Using a 4mm-hexagonal wrench,

fully open the valve rods.

Ball valve

Using a flathead screwdriver, turn it counterclockwise by 90° until it hits the

stopper. (Full open)

Balance pipe

Balance packed valve

Using a 4mm-hexagonal wrench, fully open the valve rods.

Gas side

Ball valve

Using a minus screwdriver, turn it counterclockwise by 90° until it hits the stopper.

(Full open)

Using flathead

screwdriver, turn it

counterclockwise by

90° until it hits the

stopper. (Full open)

Service

port

Flare nut

Valve unit

(1)

(2)

Fully closed

Fully opened

Slot

Position of screwdriver slot

* When opened fully, do not apply

excessive torque after the screwdriver hits

the stopper; otherwise a problem may be

caused on the valve. (5 N•m or less)

Fully closed

Fully opened

F-GAS label

This product contains fluorinated greenhouse gases covered by the Kyoto Protocol

• Chemical Name of Gas R410A

• Global Warming Potential (GWP) of Gas 1975

CAUTION

1. Stick the enclosed refrigerant label adjacent to the charging and/or recovering location.

2. Clearly write the charged refrigerant quantity on the refrigerant label using indelible ink. Then, place the included

transparent protective sheet over the label to prevent the writing from rubbing off.

3. Prevent emission of the contained fluorinated greenhouse gas. Ensure that the fluorinated greenhouse gas is

never vented to the atmosphere during installation, service or disposal. When any leakage of the contained

fluorinated greenhouse gas is detected, the leak shall be stopped and repaired as soon as possible.

4. Only qualified service personnel are allowed to access and service this product.

5. Any handling of the fluorinated greenhouse gas in this product, such as when moving the product or recharging

the gas, shall comply under (EC) Regulation No. 842/2006 on certain fluorinated greenhouse gases and any

relevant local legislation.

6. Periodical inspections for refrigerant leaks may be required depending on European or local legislation.

7. Contact dealers, installers, etc., for any questions.

Heat insulation for pipe

• Apply heat insulation of pipe separately at the liquid, gas, and balance sides.

• Be sure to use thermal insulator resistant up to 120°C or higher for pipes at the gas side.

Finishing after connecting pipes

• After piping connection work has been finished, cover the opening of the piping/wiring panel with the piping

cover, or fill silicon or putty into the space between the pipes.

• In case of drawing-out the pipes downward or sideward, also close the openings of the base plate and the side

plate.

• Under the opened condition, a problem may be caused due to the entering of water or dust.

R410A

kg

kg

kg

Pre-charged Refrigerant at Factory [kg],

specified in the nameplate

Additional Charge on Installation Site

[kg]

33-EN 34-EN

+00EH99871699_01EN.book Page 17 Thursday, August 26, 2010 4:41 PM