45

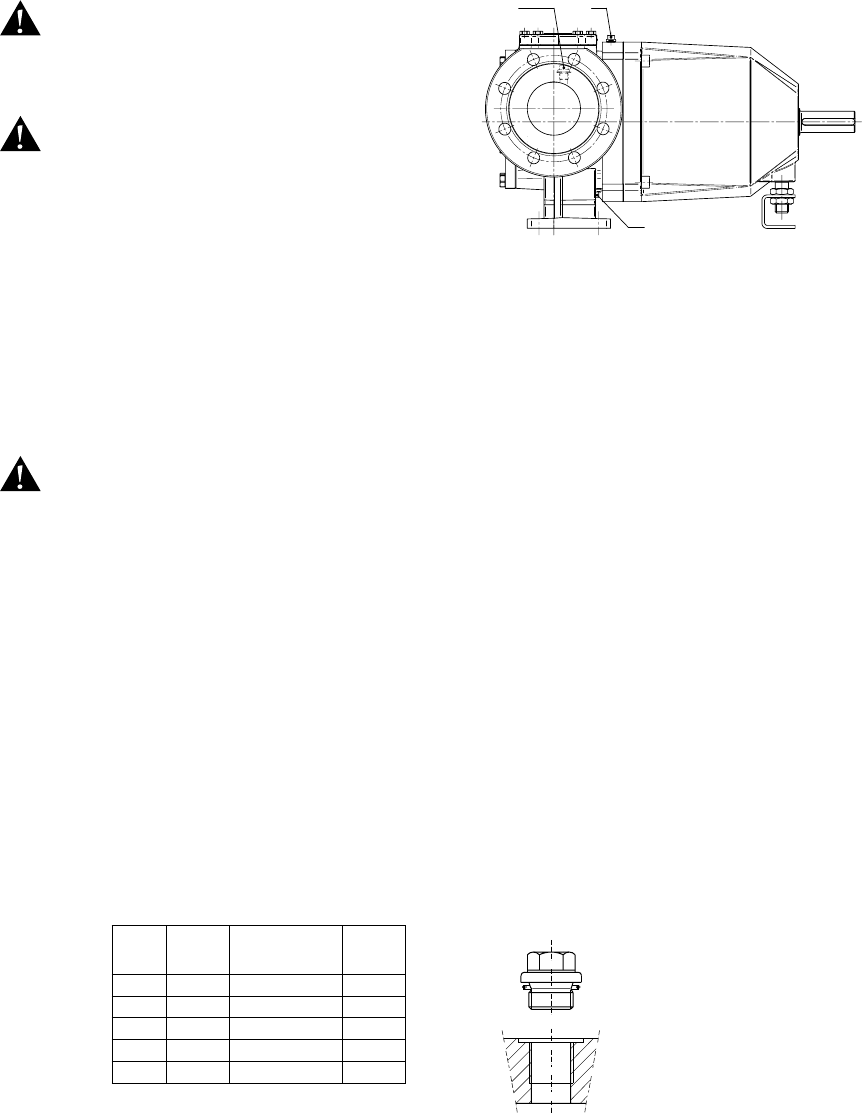

2x Be Bb

Ba

A.0500.551 – IM-TGMAG/02.00 EN (02/2008)

• Foruidsthatsolidifyorbecomeveryviscous

at ambient temperature, it is best to empty

the pump immediately after shutting down

by separating it from the piping. Always wear

safety goggles and gloves.

• Protectyourselfwithaprotectivecap.The

fluid may spray out of the pump.

• OpentheventingplugsBeandBb.

• Ifnodrainlineisprovided,takeprecautions

so that the liquid is not contaminating the

environment.

• OpenthedrainplugBaatthebottomofthepumphousing.

• Letdraintheliquidbygravity.

• Purge pump spaces with flush media or cleaning liquid by connecting a purge system to the

following inlet openings:

- Ba, Be: plugs close to both flanges for purging the pump casing part

- Bb: plug on top of the intermediate cover for purging the magnetic coupling

Note: If toxic liquids were pumped special precautions regarding flushing/cleaning of the pump

and personal protection equipment must be taken before disassembling the pump.

• Re-assembletheplugsandclosethevalves,ifany.

3.21.2.9 Fluid circuits

• Depressurizethejacketsandtheretaininguidcircuits.

• Uncoupletheconnectionstothejackets.

• Ifnecessary,cleanthejacketsandthecircuitswithcompressedair.

• Avoidanyleakageofuidorthermaloilintotheenvironment.

3.21.3 Specific components

3.21.3.1 Nuts and bolts

Nuts and bolts showing damage or parts with defective threading must be removed and replaced

with parts belonging to the same fixation class as soon as possible.

• Preferablyuseatorquewrenchfortightening.

• Forthetighteningtorques,seetablebelow.

3.21.3.2 Plastic or rubber components

• Donotexposecomponentsmadeofrubberorplastic(cables,hoses,seals)totheeffectsofoils,

solvents, cleaning agents or other chemicals unless they are suitable.

• Thesecomponentsmustbereplacediftheyshowsignsofexpansion,shrinkage,hardeningor

other damage.

3.21.3.3 Flat gaskets

• Neverre-useatgaskets.

• Alwaysreplacetheatgasketsandelasticringsundertheplugswithgenuinespares.

Plug with edge and elastic washer

Bolt

Ma (Nm)

8.8 / A4

Plug with

edge and flat

seal

Ma (Nm)

M6 10 G 1/8 10

M8 25 G 1/4 20

M10 51 G 1/2 50

M12 87 - -

M16 215 - -