33

A.0500.551 – IM-TGMAG/02.00 EN (02/2008)

3.18.5.2 Piping

• Use piping with a diameter equal to or greater than the connection ports of the pump and with

the shortest possible lengths.

• Thepipediameterhastobecalculatedinfunctionoftheliquidparametersandtheinstallation

parameters. If necessary use larger diameters to limit pressure losses.

• Iftheuidtobepumpedisviscous,pressurelossesinthesuctionanddischargelinesmay

increase considerably. Other piping components like valves, elbows, strainers, filters and foot

valve also cause pressure losses.

• Diameters,lengthofpipingandothercomponentsshouldbeselectedinsuchawaythatthe

pump will operate without causing mechanical damage to the pump/pump unit, taking into

account the minimum required inlet pressure, the maximum allowable working pressure and the

installed motor power and torque.

• Checkthetightnessofthepipesafterconnection.

Suction piping

• Liquidsshouldenterthepumpfromalevelhigherthanthepumplevel,theincliningpipeshould

rise upwards towards the pump without any air pockets.

• Atoosmalldiameteroratoolongsuctionpipe,atoosmallorblockedstrainerwillincrease

pressure losses so that the NPSHa (NPSH available) becomes smaller than the NPSH (NPSH

required).

Cavitation will occur, causing noise and vibrations. Mechanical damage to pump and pump unit

may occur.

• Whenasuctionstrainerorlterisinstalledpressurelossesinthesuctionlinemustbechecked

constantly. Also check if the inlet pressure at the suction flange of the pump is still sufficiently

high.

Self-priming operation

At the start sufficient liquid must be available in the pump filling up the internal clearance volume and

the dead spaces, allowing the pump to build up a pressure difference.

Therefore, for pumping low viscosity fluids, a foot valve with the same or larger diameter than the

suction pipe must be installed or the pump can be installed without foot-valve but in U-line.

Note! A foot valve is not recommended when pumping high viscous liquids.

• Toremoveairandgasesfromsuctionlineandpump,counterpressureatthedischargeside

must be reduced. In case of self-priming operation, start-up of the pump should be performed

with open and empty discharge line allowing air or gases to escape at low backpressure.

• Anotherpossibilityincaseoflonglinesorwhenanon-returnvalveisinstalledinthedischarge

line, is to install a by-pass with isolating valve close to the discharge side of the pump. This valve

will be opened in case of priming and allows air or gas evacuation at low backpressure.

• Thebypassshouldbeleadbacktothesupplytank–nottothesuctionport.

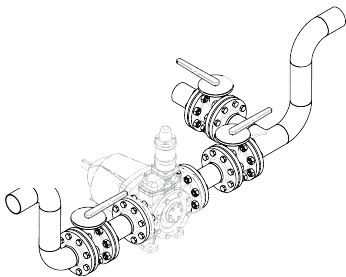

3.18.5.3 Isolating valves

To allow proper maintenance it is necessary to be

able to isolate the pump. Isolation can be done by

installing valves in suction and discharge lines.

• Thesevalvesmusthaveacylindricalpassageof

the same diameter of the piping (full bore). (Gate

or ball valves are preferable).

• Whenoperatingthepump,thevalvesmust

be opened completely. The output must never

be regulated by means of closing valves in

suction or discharge pipes. It must be regulated

by changing shaft speed or by re-routing the

media over a by-pass back to the supply tank.

Discharge

By-pass

Piping

Suction