7

TopGear

Serial No:

Model: TG

SPX Process Equipment BE NV

Evenbroekveld 2-4

BE-9420 Erpe-Mere

www.johnson-pump.com and spxpe.com

A.0500.551 – IM-TGMAG/02.00 EN (02/2008)

1.0 Introduction

1.1 General

This instruction manual contains necessary information on the TopGear pumps and must be read

carefully before installation, service and maintenance. The manual must be kept easily accessible to

the operator.

Important!

The pump must not be used for other purposes than recommended and quoted for without

consulting your distributor.

Liquids not suitable for the pump can cause damages to the pump unit, with a risk of personal injury.

1.2 Reception, handling and storage

1.2.1 Reception

Remove all packing materials immediately after delivery. Check the consignment for damage

immediately on arrival and make sure that the name plate/type designation is in accordance with the

packing slip and your order.

In case of damage and/or missing parts, a report should be drawn up and presented to the carrier at

once. Notify your distributor.

All pumps have the serial number

stamped on a nameplate.

This number should be stated in

all correspondence with your distributor.

The first two digits of the serial

number indicate the year of production.

1.2.2 Handling

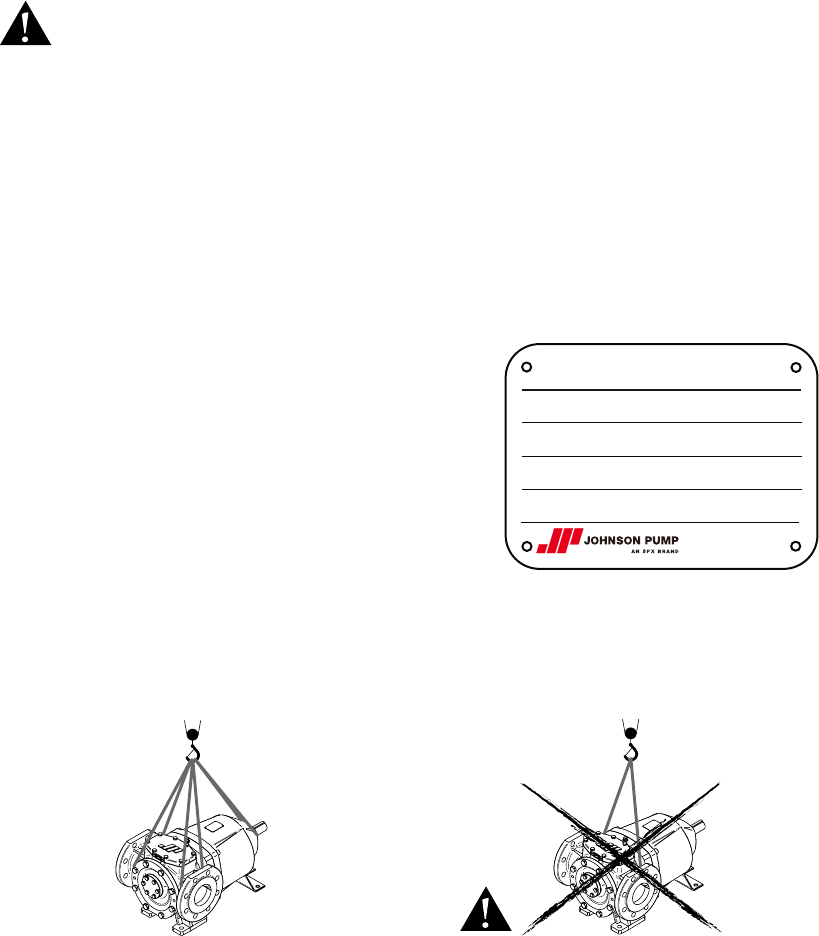

Check the mass (weight) of the pump unit. All parts weighing more than 20 kg must be lifted using

lifting slings and suitable lifting devices, e.g. overhead crane or industrial truck. See section 6.6

Weights – Mass.

Never lift the pump unit with only two fastening

points. Incorrect lift can cause personal injury

and/or damage to the pump unit.

Always use two or more lifting slings. Make sure

they are secured in such a way as to prevent

them from slipping. The pump unit should be

lifted in a horizontal position.

1.2.3 Storage

If the pump is not commissioned immediately, the shaft should be turned a full turn once every week.

This ensures a proper distribution of the protective oil.