60

0040

0600

8120

8110

8100

4000

1410

1700

A

S B

0702

1400

Tool

8330

8450

0701

0010

A.0500.551 – IM-TGMAG/02.00 EN (02/2008)

TG MAG

Axial clearance C

[mm]

15-50 0.120 – 0.200

23-65 0.125 – 0.215

58-80 0.150 – 0.250

86-100 0.165 – 0.275

185-125 0.190 – 0.320

4.3.5 Assembly of the bearing bracket

1. Place the pump vertically on the workbench with the

separation can (8330) pointed upwards.

2. Screw the 4 guiding pins (tool) into the threaded holes of

the cap head screws (1410).

3. Screw a lifting eye bolt into the shaft end of pump shaft

(0702).

4. Use a crane to fit the bearing bracket (1400) over the

guiding pins to the intermediate cover from the top (see

picture).

5. Remove the guiding pins and fit cap head screws (1410).

Tighten cap head screws (1410) crosswise to fix the

bearing bracket (1400) to the intermediate cover (8450).

6. Mount bearing bracket support (1700) to the bearing

bracket (1400).

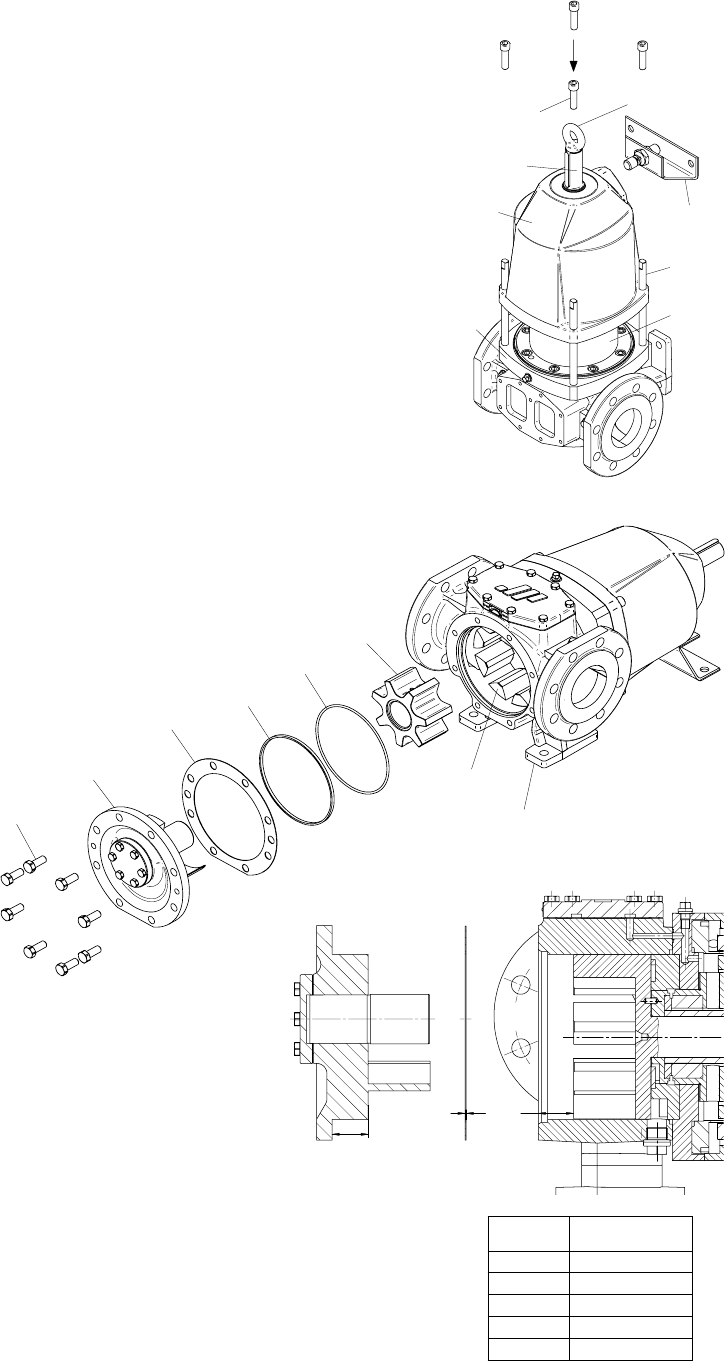

4.3.6 Assembly of the front-pull-out assembly

1. Check that the contact faces and O-ring chamber

are not damaged and free of dirt. Check the condi-

tion of O-ring (8120), in case of doubt replace the

O-ring with a new one.

2. Measure the distances as indicated

on the sketch.

3. Calculate the required thickness of the shim (8100)

between pump cover (4000) and pump casing (0010).

S = A – B + C. Axial clearance C between rotor shaft

(0701) and pump cover (4000) – see table.

Lifting eye bolt