34

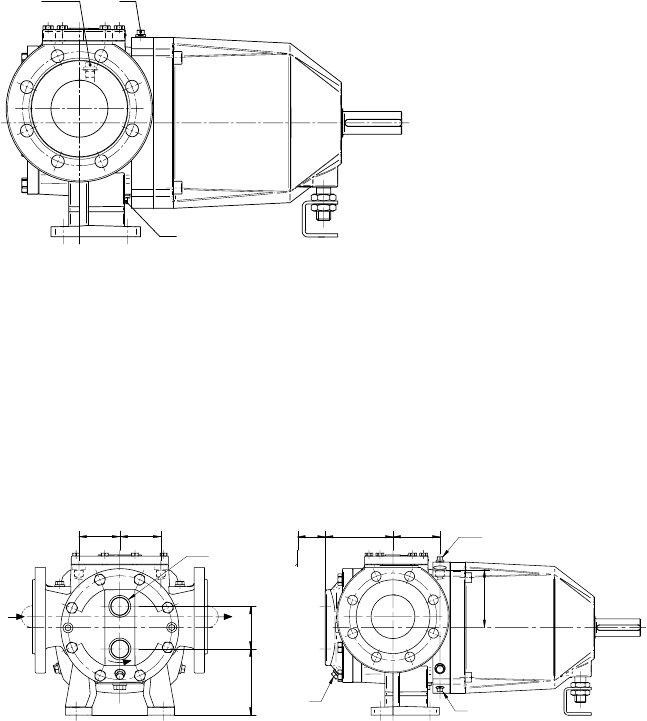

2xBl

ma zg

Bh

dhdg

zh

Bg

dk dk

2xBf

dl

2x Be

Bb

Ba

A.0500.551 – IM-TGMAG/02.00 EN (02/2008)

3.18.5.4 Strainer

Foreign particles can seriously damage the pump. Avoid the entry of these particles by installing a

strainer.

• Whenselectingthestrainerattentionshouldbegiventothesizeoftheopeningssothatpres-

sure losses are minimised. The cross-sectional area of the strainer must be three times that of

the suction pipe.

• Installthestrainerinsuchawaythatmaintenanceandcleaningarepossible.

• Makesurethatthepressuredropinthestraineriscalculatedwiththerightviscosity.Heatthe

strainer if necessary to reduce viscosity and pressure drop.

For the maximum allowable particle size see section 3.15.

3.18.6 Secondary piping

For dimensions of connections and plugs see chapter 6.0.

3.18.6.1 Drain lines

The pump is provided with a drain plug.

3.18.6.2 Heating jackets

1. S-type jackets

The S-jackets are designed for use with saturated steam (max 10 bar, 180°C) or with non-dangerous

media. They are provided with threaded connections Bl (see chapter 6.0 for the dimensions).

The connection can be done by threaded pipes or pipe connections with sealing in the thread

(conical thread applying ISO 7/1) or sealed outside the thread by means of flat gaskets (cylindrical

thread applying ISO 228/1). Thread type see section 3.21.7.

S-jacket on the pump cover

2. T-type jackets

The T-jackets are provided with special steel flanges (delivered with the pump) on which the pipes

should be welded properly by qualified personnel. The jackets are made of nodular iron or other

ductile material. For pipe dimensions of Cf see chapter 6.0.