46

A.0500.551 – IM-TGMAG/02.00 EN (02/2008)

3.21.3.4 Filter or suction strainer

Any filters or suction strainers at the bottom of the suction line must be cleaned regularly.

Note! A clogged filter in the suction piping may result in insufficient suction pressure at the inlet.

Clogged filter in the discharge line may result in higher discharge pressure.

3.21.3.5 Anti-friction bearings

TG MAG pumps are equipped with 2RS ball bearings which are grease packed for life. They do not

require periodical greasing. The bearings should be replaced after 25.000 operating hours.

3.21.3.6 Sleeve bearings

We recommend checking the pump regularly for wear on the gear wheels and sleeve bearings to

avoid excessive wear of other parts.

• Aquickcheckcanbedonebyusingthefrontpull-outandbackpull-outsystem.Seetablefor

maximum allowable radial clearance of the sleeve bearings.

• Forreplacementofthesleevebearingscontactyourdistributor.

TG MAG pump size

Maximum allowed

radial clearances

15-50 to 23-65 0.15 mm

58-80 to 86-100 0.25 mm

185-125 0.30 mm

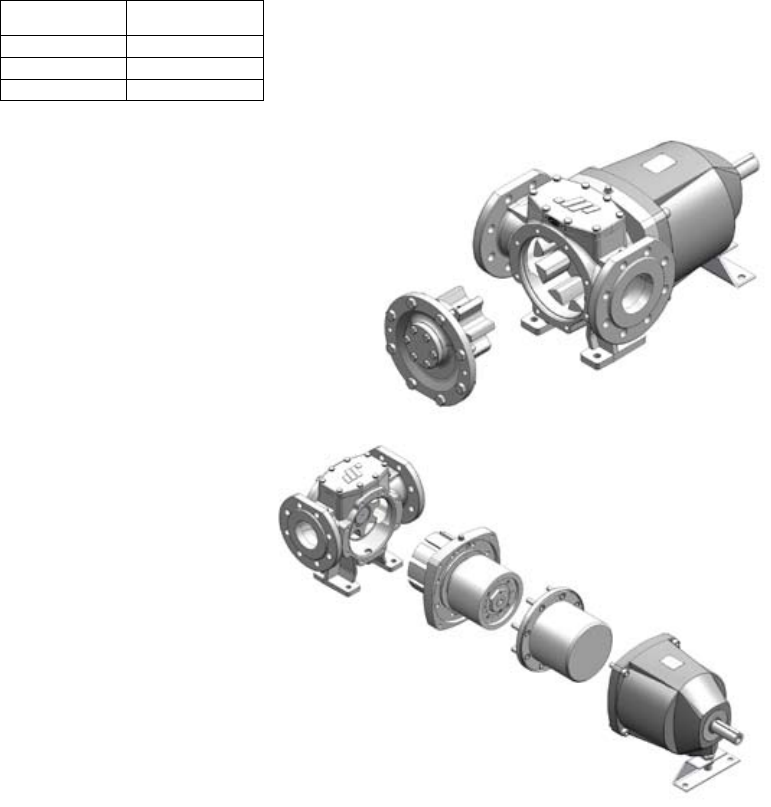

3.21.4 Front pull-out

The TG-pumps have a front pull-out system.

To remove liquid residues or to check the

idler bearing for wear, the pump cover can

be pulled out from the pump housing without

disconnecting suction and discharge pipes.

See chapters 4.0 Disassembly/Assembly and

section 6.6 Weights.

3.21.5 Back pull-out

To flush the pump or to check

the rotor shaft bearing

arrangement the bearing

bracket with outer magnetic

rotor and the rotor shaft/

bearing assembly can be

pulled out backwards without

disconnecting the suction

and discharge pipes.

When a spacer coupling is used, the driving

mechanism need not be moved.

See chapters 4.0 Disassembly/Assembly and section 6.6

Weights. for the mass (weight) of the components.

3.21.6 Clearance adjustment

The TG pumps are delivered with the correct axial clearance setting. In some cases, however, the

axial clearance needs to be adjusted:

• When uniform rotor and idler wear need to be compensated by re-setting the axial clearance.

• When pumping low viscous liquids the slip can be reduced by decreasing the axial clearance.

• When the liquid is more viscous than expected, the friction inside the pump can be reduced by

increasing the axial clearance.